Welding temperature of various electronic components

Date:2023-04-23 16:35:24 Views:5908

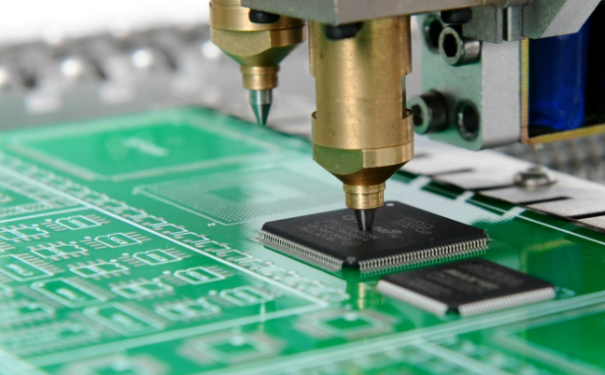

Welding is a very important step in the electronic manufacturing process, which involves the assembly and connection of electronic components. Welding temperature is an important parameter that affects the performance and quality of electronic components. In this article, we will introduce the welding temperatures of various electronic components and how to choose the appropriate welding temperature.

Welding temperature of solder and solder

Solder and solder are commonly used welding materials in electronic manufacturing. The welding temperature of solder is usually between 260 and 320 ° C, while the welding temperature of tin solder is usually between 200 and 250 ° C. Too high a welding temperature can lead to the melting and volatilization of solder and solder, thereby affecting the welding effect. If the welding temperature is too low, it may cause solder and solder to not firmly connect electronic components, thereby affecting the performance and quality of the components.

Welding temperature of electronic components

The welding temperature of electronic components is also very important. Different types of electronic components require different welding temperatures. For example, the welding temperature of a PCB (printed circuit board) is usually between 260 and 320 ° C, while the welding temperature of a capacitor is usually between 280 and 300 ° C, and the welding temperature of an inductor is usually between 250 and 280 ° C. If the welding temperature is not appropriate, it may lead to a decrease in the performance of electronic components and even damage them.

Measurement of welding temperature

The measurement of welding temperature is also very important. Usually, thermocouples or infrared detectors can be used to measure welding temperature. Thermocouples can directly measure the temperature of solder and solder, while infrared detectors can measure the temperature around electronic components. When selecting measurement equipment, it is necessary to consider the type of welding equipment and the type of welding material.

Control of welding temperature

The control of welding temperature is very important for electronic manufacturing. During the welding process, it is necessary to ensure that the welding temperature is within the appropriate range to ensure the welding effect and the quality of electronic components. Usually, the welding temperature can be controlled through a control system. The control system can monitor the welding temperature in real-time and make adjustments as needed.

Welding temperature is a very important parameter in electronic manufacturing, which can affect the performance and quality of electronic components. When selecting the welding temperature, it is necessary to consider the welding temperature of solder and solder, the welding temperature of electronic components, and the welding temperature of welding equipment. In addition, it is necessary to ensure that the welding temperature is within the appropriate range to ensure the welding effect and the quality of electronic components.

The above is the content related to the "welding temperature of various electronic components" brought by this core detection. We hope it can be helpful to everyone, and we will bring more exciting content in the future. The company's testing services cover various testing projects, including electronic component testing and verification, IC authenticity identification, product design and material selection, failure analysis, functional testing, factory incoming material inspection, and tape weaving. Welcome to call Chuangxin Testing, we will be happy to serve you.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou