Lock the source of chip failure from the outside in and tell you how to prevent the popcorn effect

Date:2024-04-02 16:47:00 Views:2664

A small component, from transportation, storage, to production line processes, ultimately being successfully installed on the machine is not as simple as imagined. There are important points to pay attention to in every aspect. If the failure of components causes the PCBA to malfunction, the troubleshooting work will be very cumbersome. Moreover, for general terminal manufacturers, even if a specific component issue is identified, due to limitations, it is not possible to thoroughly investigate its root cause.

Chuangxin Testing has accumulated experience in long-term customer service, and our work is not only to accurately identify the cause of failure, but also to provide practical and feasible suggestions to help customers avoid similar problems.

1、 Case background

The PCBA of a certain electrical product from the end customer was found to have no output after SMT testing, and it was ultimately found to be caused by the lack of output from the operational amplifier. This issue has led to an emergency online shutdown, and customers urgently need to identify the root cause of the failure. After receiving user requirements and intervening, Chuangxin Testing started with the failed operational amplifier and identified the cause through methods such as appearance inspection, electrical characteristic testing, X-ray testing, SAT analysis, and cover opening inspection.

2、 Analysis process

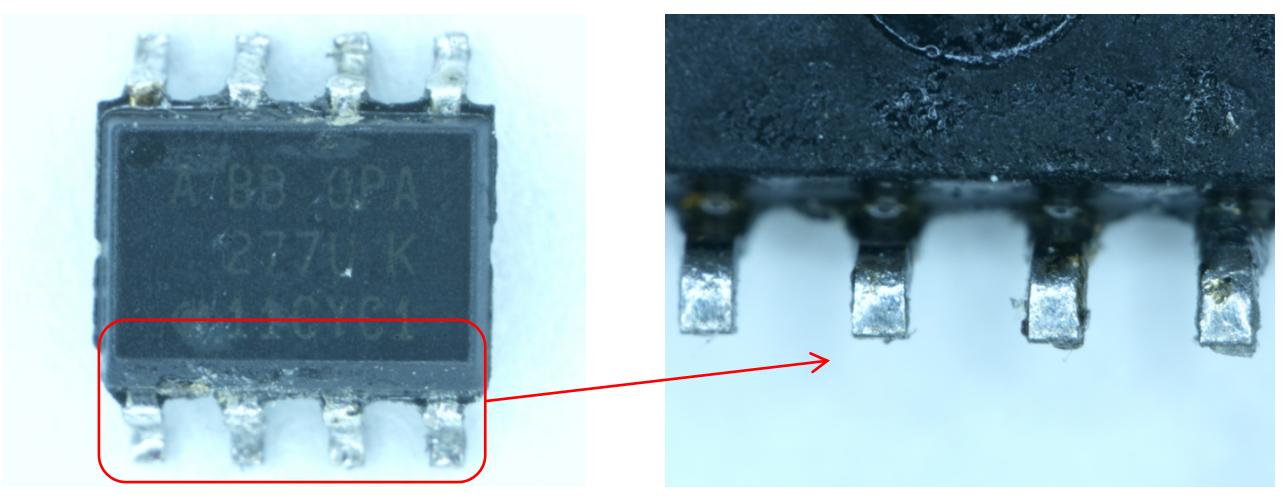

1. Visual inspection

A visual inspection was conducted on the defective amplifier, and no obvious abnormalities such as edge collapse, cracks, holes, or polishing were found in the packaging of the amplifier; The pin coating is intact and shows no obvious signs of oxidation or corrosion.

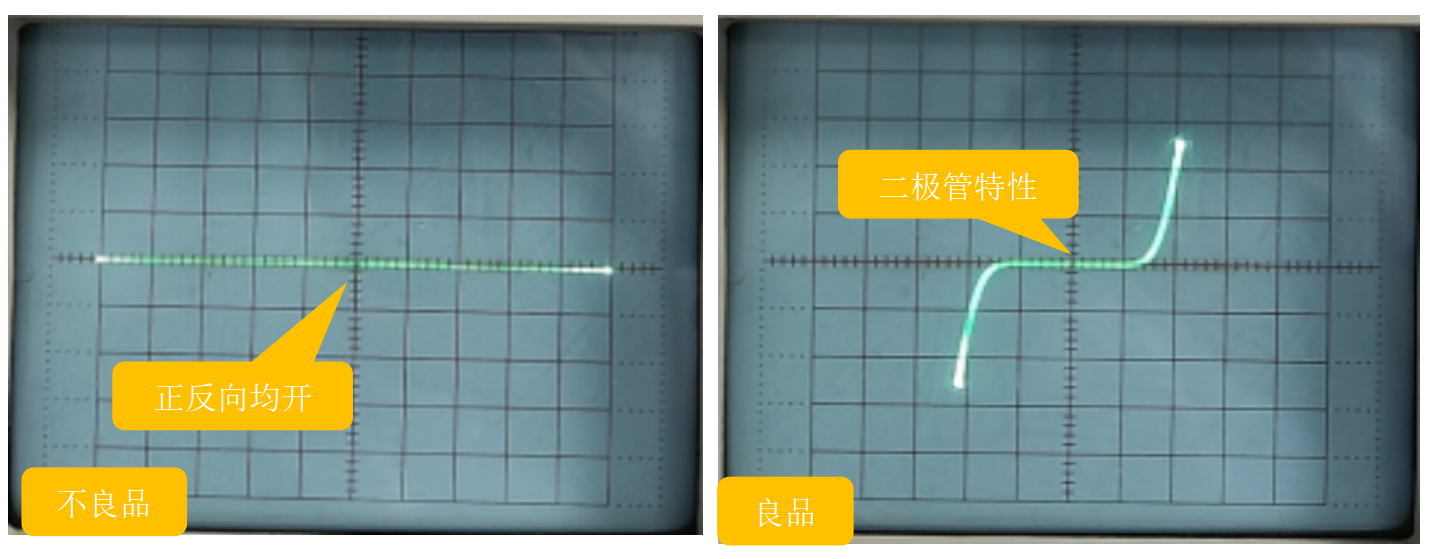

2. Electrical characteristic testing

The electrical characteristics of the defective operational amplifier and the good product were tested, and the characteristic curves of the same pin to ground or power pin were compared for any significant differences. The results showed that a certain IO pin of the defective product had a significant open circuit to the VCC, while the good product had normal diode characteristics. Therefore, it is suspected that the defective product may have an internal bonding open circuit.

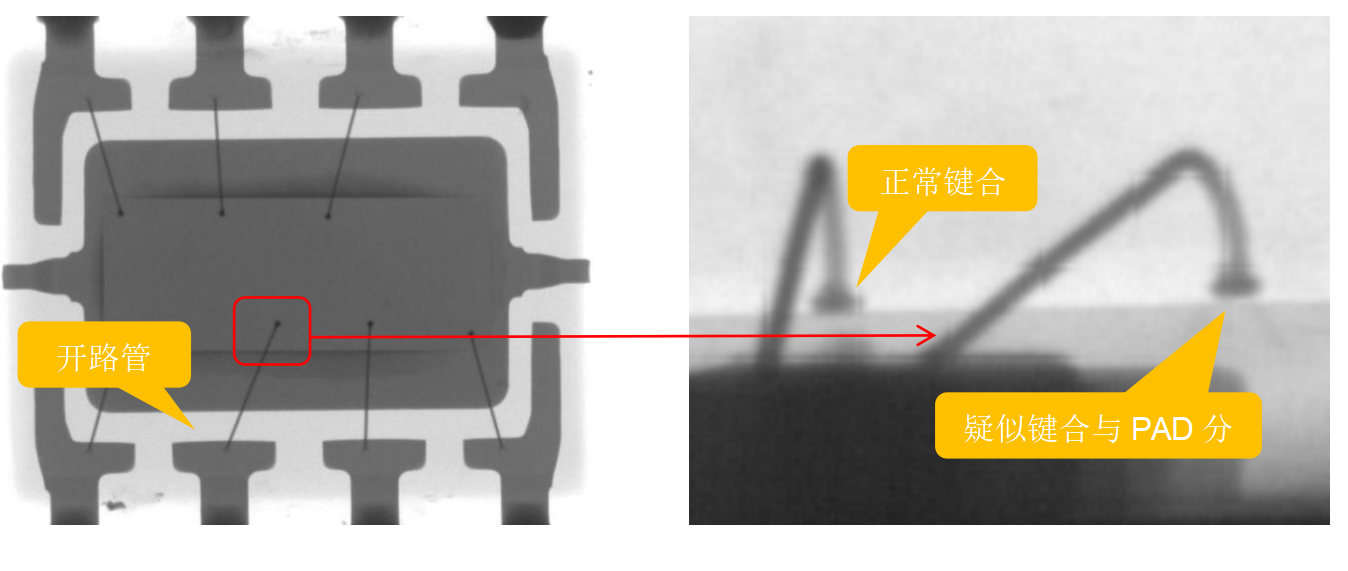

3. X-ray examination

Due to the analysis of electrical characteristics, it was found that the defective pin had a significant open circuit to the power supply. Therefore, X-ray inspection was conducted on it, with a focus on observing the internal bonding morphology. It was found that the first bonding of the pin was suspected to be separated from the PAD.

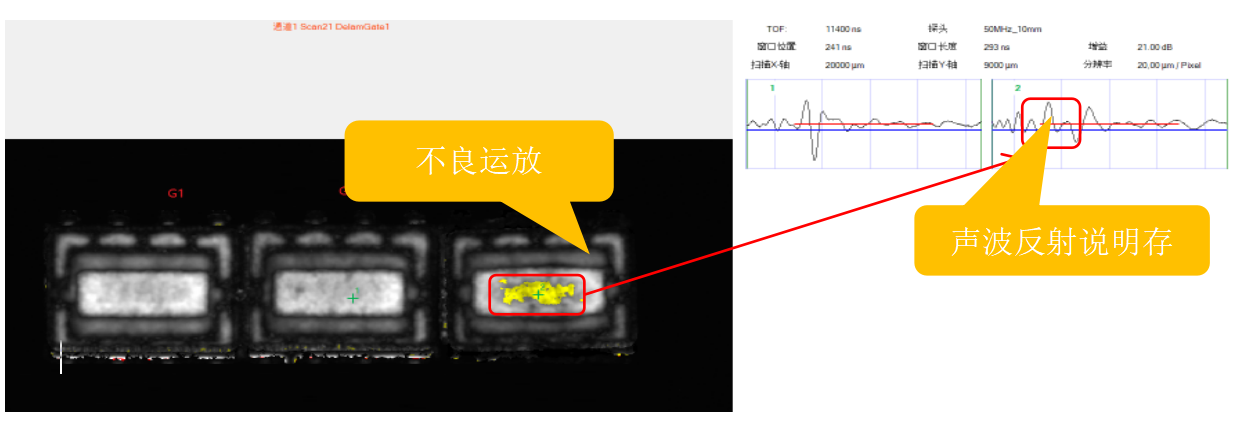

4. SAT analysis

Based on the electrical characteristics and X-ray analysis results, perform ultrasonic scanning (SAT) on defective products. This test is based on the principle that different materials have different echoes, and is particularly suitable for detecting structural layering inside packaging. We explored the possibility of bonding cracking caused by delamination of the plastic packaging body through SAT testing, and found that there was a slight delamination between the surface of the defective amplifier die and the plastic packaging body, while the good product did not exhibit this behavior. Based on this, we speculate that the delamination phenomenon of the defective product is related to bonding cracking, and this delamination phenomenon is similar to the popcorn effect.

5. Open lid inspection

To accurately and thoroughly identify the cause of failure, we conducted an open cover inspection on the defective operational amplifier, focusing on observing the suspected open circuit bonding point. Under a 3D microscope, it can be observed that the bonding point has completely detached from the PAD (pad that receives the pin), indicating that the pin is indeed in an open circuit state.

3、 Identify the failure mechanism

From the analysis results, it can be seen that the direct cause of poor operational amplifier failure is the separation of pin bonding and PAD; The root cause is the popcorn effect, which causes delamination between the plastic packaging and the die surface, thereby exerting an upward force on the bonding wire, ultimately leading to open circuit failure of the bonding. The hidden dangers of the popcorn effect have already been buried in the storage and transportation of electronic components.

Popcorn effect: In general, materials are prone to moisture absorption during storage, and water vapor in the atmosphere slowly diffuses into the interior of the IC plastic packaging. In the SMT process, the heating of water vapor increases the internal pressure of the IC, causing delamination and separation between the plastic packaging and the die surface at a certain pressure node.

4、 Preventive measures: Always pay attention to moisture-proof measures

The core of preventing the popcorn effect is to pay attention to moisture prevention. Generally, integrated circuits (ICs) are non airtight moisture sensitive devices (MSDs) that are connected to the PCB through pins. For moisture sensitive devices, there is a standardized moisture sensitivity level (MSL) classification that specifies the storage conditions for each type of device:

Level 1- Less than or equal to 30 ℃/85% RH infinite workshop life

Level 2- workshop life less than or equal to 30 ℃/60% RH for one year

Level 2a - Less than or equal to 30 ℃/60% RH four week workshop life

Level 3- workshop life less than or equal to 30 ℃/60% RH 168 hours

Level 4- workshop life less than or equal to 30 ℃/60% RH 72 hours

Level 5- workshop life less than or equal to 30 ℃/60% RH for 48 hours

Level 5a - workshop life less than or equal to 30 ℃/60% RH for 24 hours

Level 6- Before use, it must be baked and refluxed within the time limit specified on the moisture sensitive label.

In practical operation, we suggest that the storage and use of components should directly follow the following points:

Moisture proof: Use moisture-proof bags, desiccants, moisture-proof boxes, etc. for storage, ensuring that the RH (relative humidity) is less than 10%.

Sealing: Vacuum packaging is used for sealing packaging during transportation, storage, and other processes.

Baking: If the transportation and storage environment of components cannot meet their moisture sensitivity level (MSL), baking should be carried out before SMT, usually at 125 ℃ * 8H. The baking temperature and time can also be adjusted according to the actual situation.

Professional troubleshooting, professional advice and guidance, and Chuangxin Testing are right beside you! If customers have various needs such as appearance inspection, failure analysis, reliability verification, etc., please feel free to call Chuangxin Testing. We will provide dedicated service. National hotline: 4008-655-800.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou