How does X-Ray and SAT reflect their respective expertise in imaging in different packages?

Date:2024-05-11 11:43:16 Views:3324

What is the difference between ultrasonic scanning SAT and X-Ray?

In the same laboratory, SAT and X-Ray are complementary methods, and their main difference lies in the different characteristics of the displayed samples:

X-Ray can observe the interior of the sample mainly based on differences in material density. X-Ray is not very sensitive to stratified air, and cracks and solder joints are difficult to observe through X-Ray unless the material has sufficient physical separation.

The X-ray imaging operation uses a penetration mode to obtain a composite image of the entire sample thickness. During prolonged inspection periods, placing semiconductor devices in close proximity to X-ray sources may result in damage or random electronic errors.

Due to the ability of the air layer to block the transmission of ultrasound, SAT is very sensitive to the presence of an internal air layer.

The image generated based on the reflection echo mode only needs to pass through the surface of the sample (reflection scanning mode) to determine the integrity of the welding layer, bonding layer, filling layer, coating layer, and bonding layer, which is the unique performance of SAT.

At the same time, the ultrasonic frequency used by SAT is higher than 20000 Hz, and this range of ultrasonic waves will not cause cavitation, and there is no damage to the tested components.

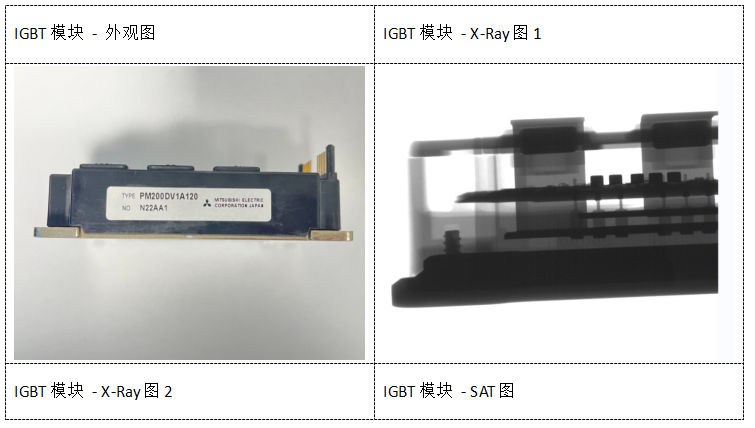

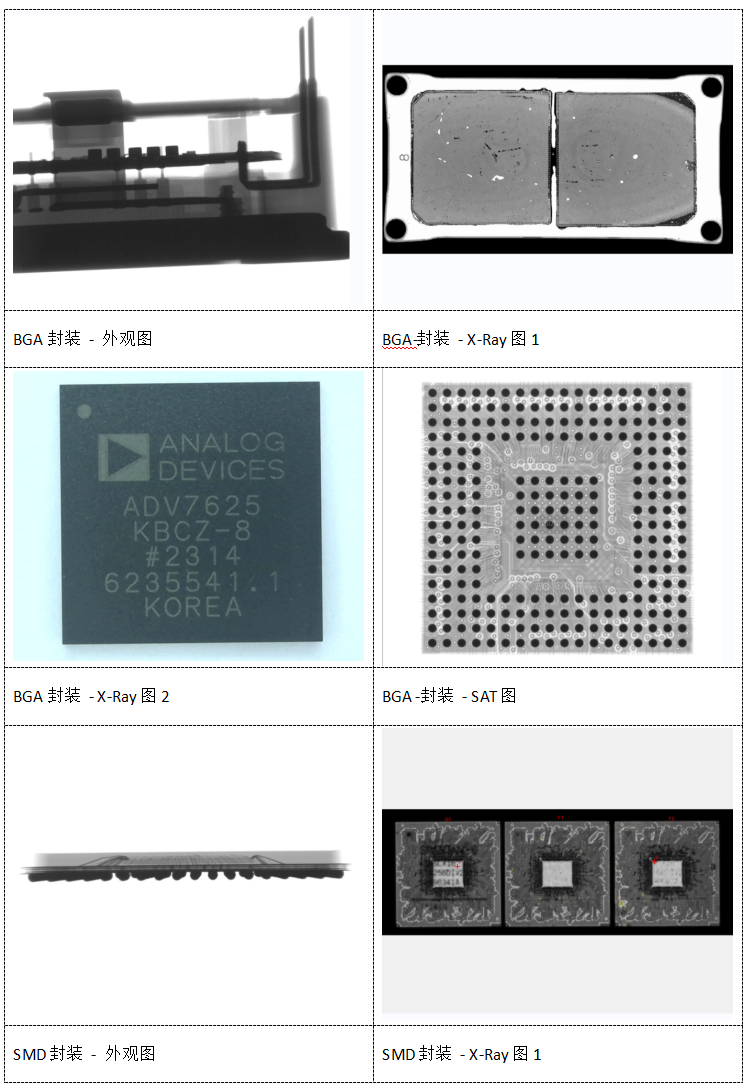

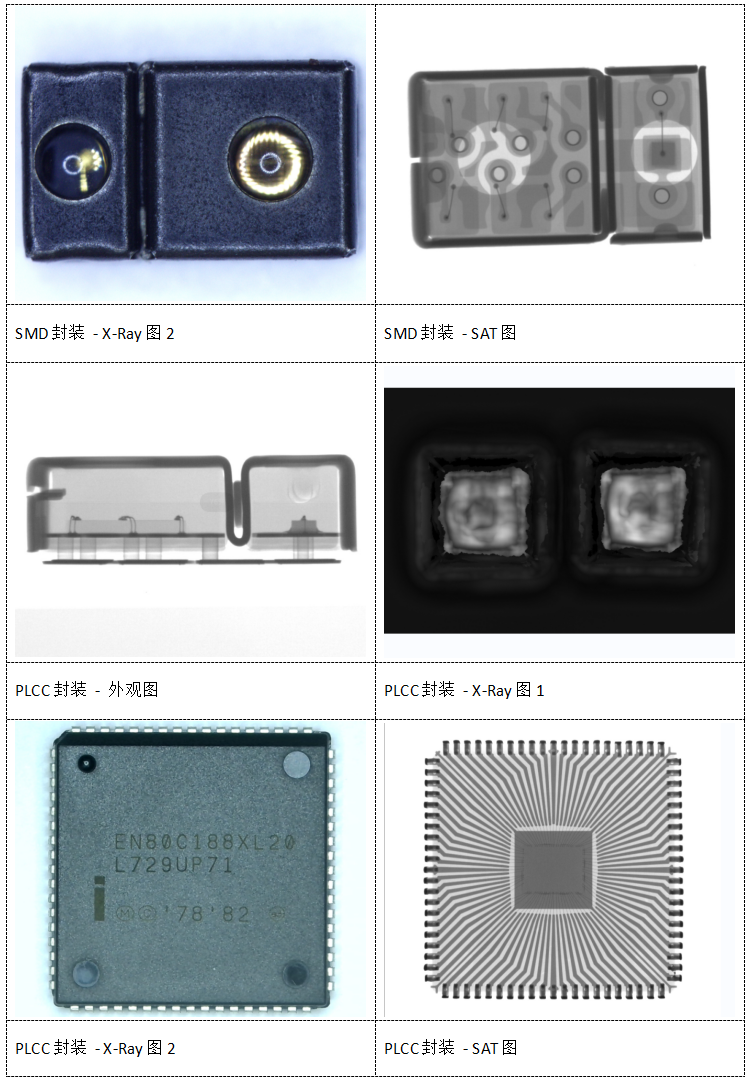

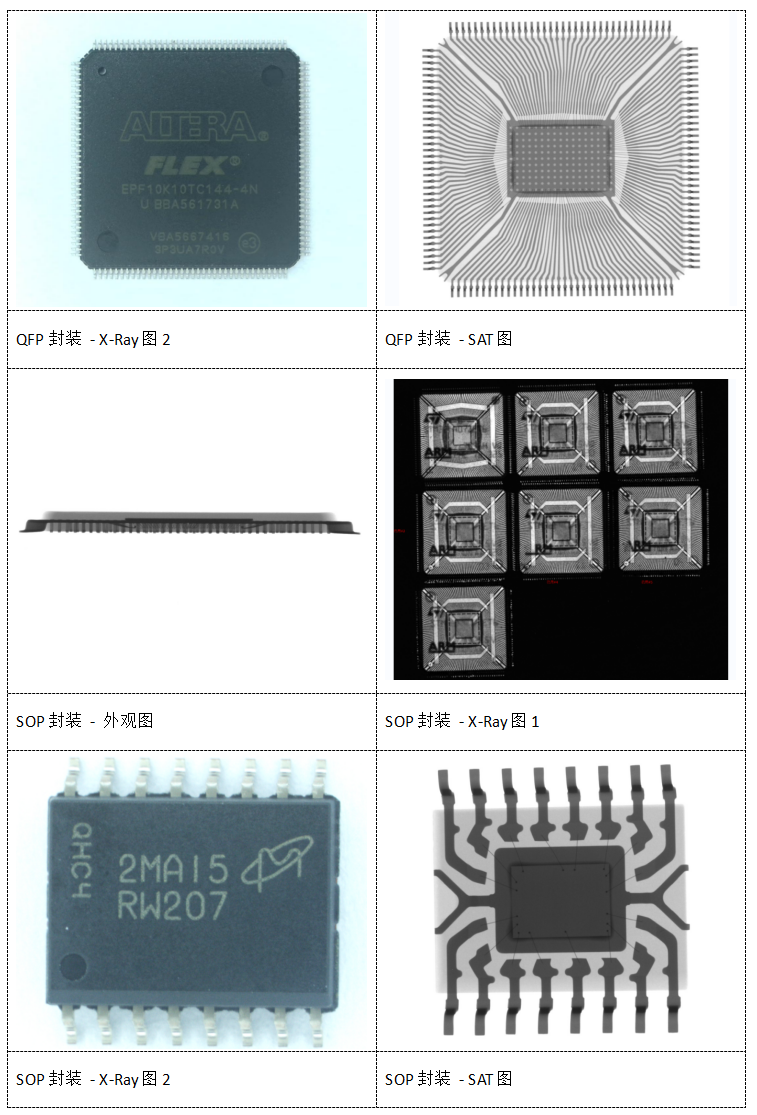

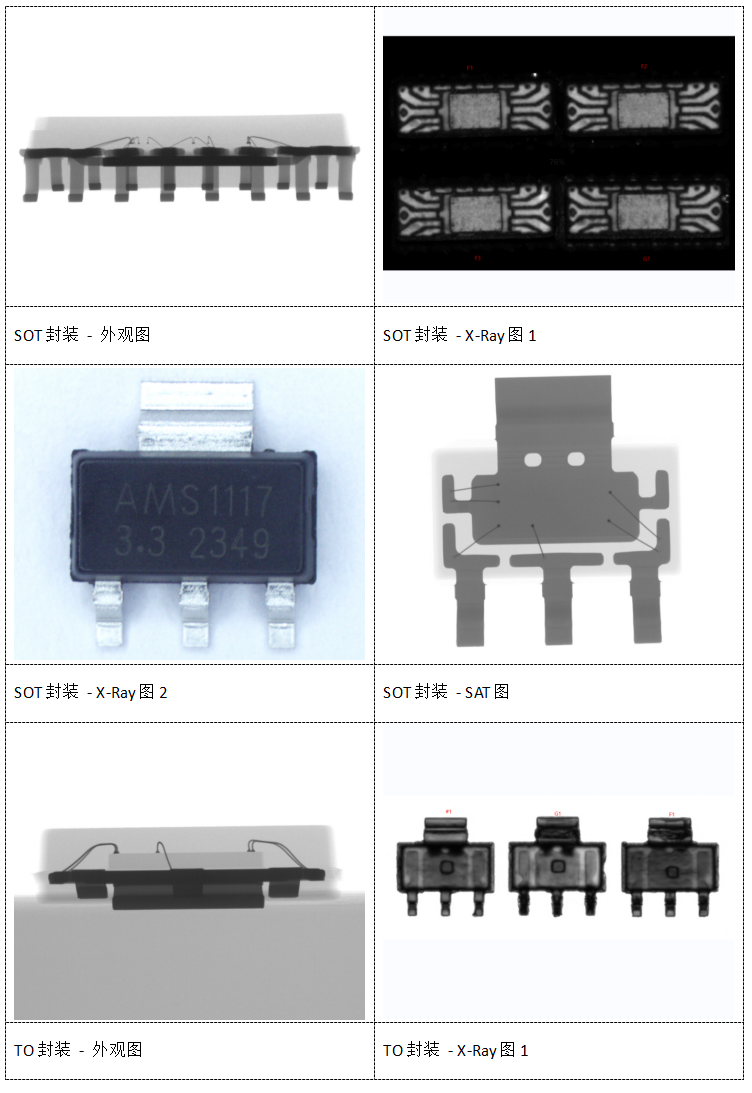

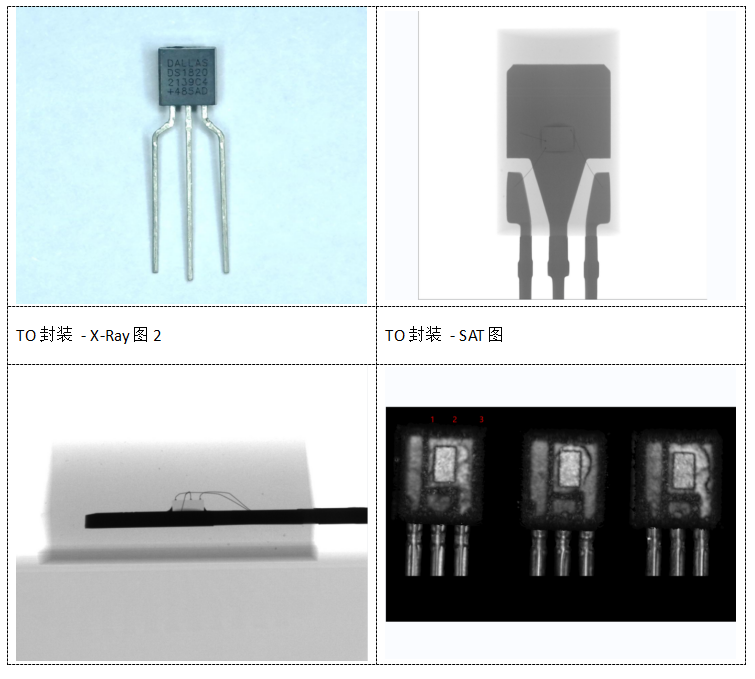

Chuangxin Testing takes you to learn about common X-ray and SAT imaging images of packaging.

(For more information, please consult customer service)

From the imaging image, X-Ray can clearly depict the internal structure of IC packaging, such as broken bonding wires, wafer cracks, and other issues. For the determination of authenticity of materials, X-Ray can also observe the differences in the internal structure for judgment. SAT is based on ultrasound, and imaging involves editing echoes from different parts and materials into grayscale images. SAT is sensitive to internal layering and specializes in detecting internal structural fractures, accurately locating problem points, and determining the size and shape of defects.

Chuangxin Testing Laboratory has a lot of practical experience. For specific cases, please refer to the previous articles on this official account. Chuangxin Testing - IC testing experts around you. If you have testing needs, please feel free to call the national hotline at 4008-655-800 at any time.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou