Common types of electronic component testing

Date:2024-07-10 15:00:00 Views:1451

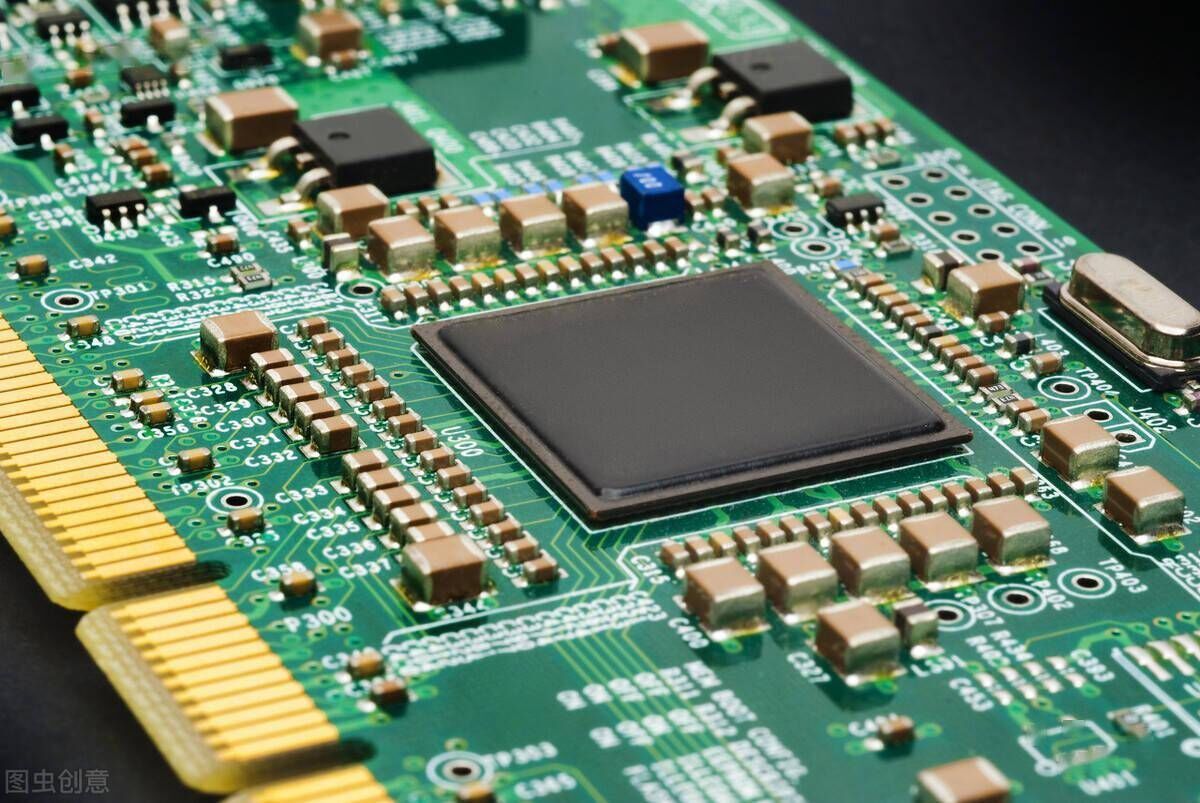

Electronic component testing is an important step in ensuring the reliability and performance of electronic devices. These tests typically involve various electrical, functional, and environmental tests on electronic components. The following are some common types of electronic component testing:

Electrical testing: including testing of parameters such as resistance, capacitance, inductance, voltage, current, etc., to ensure that the components meet the specification requirements.

Functional testing: Verify that the components are working properly according to their designed functions. For example, conducting logic functional testing on integrated circuits to ensure they operate in the manner described in the specification sheet.

Environmental testing: Testing the performance of components under different environmental conditions, such as temperature, humidity, vibration, and impact. This helps to evaluate the stability of components in various working environments.

Reliability testing: including life testing, thermal stress testing, temperature cycling testing, etc., to evaluate the reliability of components in long-term use.

EMC testing: Electromagnetic compatibility testing to ensure that components do not cause interference or are subject to external interference, and comply with relevant electromagnetic compatibility standards.

Safety testing: Verify the safety performance of components under normal and abnormal conditions to ensure that they do not pose a danger to users during use.

Cost benefit testing: Evaluate the balance between cost and performance of components to ensure the selection of the most suitable components in production.

These tests are crucial for ensuring the quality and performance of electronic products, and can help manufacturers provide reliable products to consumers.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou