What is chip slicing? How to conduct testing?

Date:2024-07-17 12:00:00 Views:1708

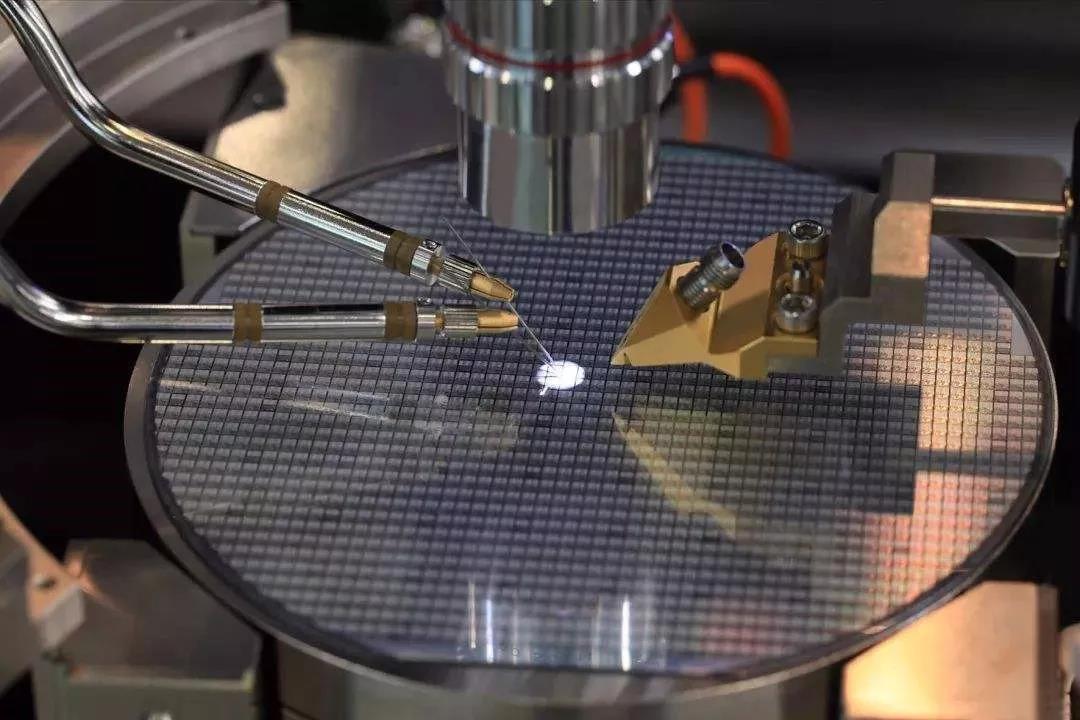

Chip slicingIt refers to cutting the entire chip into small chips or chip blocks, usually carried out during the chip production process for subsequent testing, packaging, and assembly. The main purpose of chip slicing is to divide a large chip into multiple small chips for finer processing and testing in subsequent process steps.

After slicing the chip, each small chip is usually referred to as a chip block or chip. These chip blocks can be further packaged, tested, and assembled to ultimately form finished chips for integration into electronic products.

After slicing the chip, the following testing steps are usually performed:

Visual inspection: Conduct a visual inspection of each chip block to ensure good cutting quality and no obvious damage or defects.

Electrical performance testing: Conduct electrical performance testing on each chip block, including functional testing, electrical characteristic testing, timing testing, etc., to ensure that the electrical performance of each chip block meets specifications.

Finished product testing: After the chip packaging and assembly are completed, the entire finished chip will undergo final testing to verify its functionality and performance.

Reliability testing: In some cases, reliability testing is also conducted on chip blocks, including aging testing, thermal shock testing, etc., to evaluate the performance of chips in long-term use and extreme environments.

Chip slicing and testing are crucial steps in the chip manufacturing process, ensuring the quality and performance of each chip block and improving the overall reliability and stability of the product. By conducting precise testing and validation on each chip block, potential issues can be identified early and the quality of the final finished chip can be ensured to meet requirements.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou