What are the common component analysis and testing methods for electronic components?

Date:2024-07-30 14:00:00 Views:1373

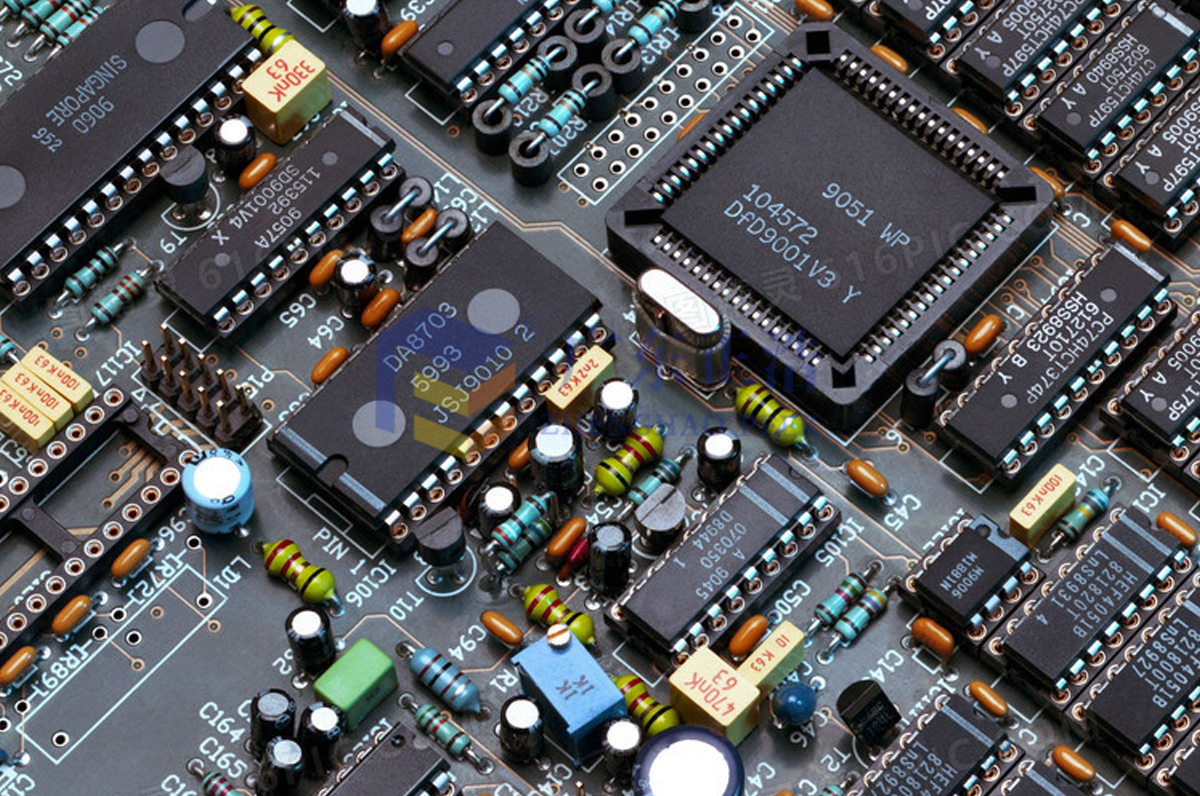

Electronic componentsComponent analysis and testing can help identify the composition, quality, and compliance of materials. Common detection methods include:

1. spectral analysis

· X-ray Fluorescence Spectroscopy (XRF)Used for rapid analysis of the elemental composition of materials, suitable for detecting both metallic and non-metallic elements.

· Energy dispersionX-ray Spectroscopy (EDS)Usually used with scanning electron microscopy(Combining SEM can provide more detailed elemental analysis.

2. chemical analysis

· Chemical titration Suitable for quantitative analysis of specific elements.

· Chromatographic methodLike gas chromatography(GC and HPLC are used for analyzing organic compounds and impurities.

3. thermal analysis

· Differential scanning calorimetry(DSC)Used to analyze the thermal properties of materials, such as melting point, glass transition temperature, etc.

· Thermogravimetric analysis(TGA)Used to measure the change in mass of materials during heating and analyze their thermal stability.

4. Microscopic analysis

· Scanning electron microscope(SEM)Used to observe the microstructure and surface characteristics of materials.

· Transmission electron microscope(TEM)Provide higher resolution microstructure analysis.

5. Mass spectrometry analysis

· Mass spectrometry method(MS)Used for analyzing molecular weight and molecular structure, suitable for component analysis of complex compounds.

6. FTIR spectroscopic analysis

· Fourier transform infrared spectroscopy(FTIR)Used for analyzing the molecular structure of materials, identifying organic compounds and polymers.

7. Comparison of Material Composition Database

· Compare the test results with the database of known materials to confirm the composition and quality of the materials.

8. Standards and specifications

· Ensure compliance with relevant industry standards and regulations (such asRoHS, REACH, etc. are tested to ensure material compliance.

9. Professional laboratory

· When high-precision and professional analysis is required, it is recommended to send it to a professional testing laboratory for comprehensive analysis.

Through these methods, the composition of electronic components can be effectively analyzed to ensure their quality and compliance. The selection of appropriate detection methods usually depends on specific analysis requirements and material properties.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou