The main steps of integrated circuit failure analysis

Date:2024-08-05 14:00:00 Views:2187

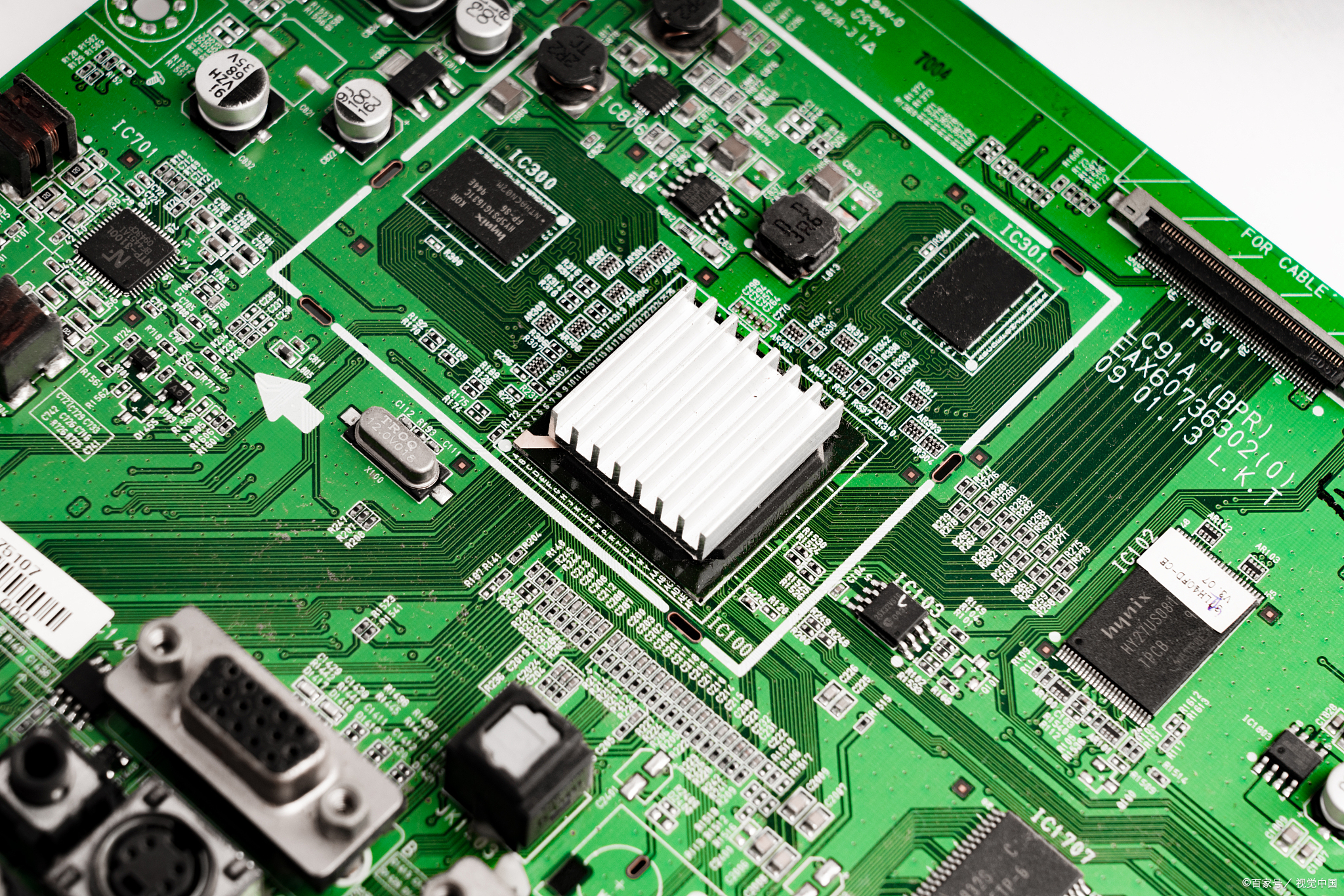

Integrated circuitThe failure analysis of IC is a systematic process aimed at identifying and addressing the root causes of IC failure. The following are the main steps of integrated circuit failure analysis:

1. data collection

· Failure recordCollection FailureInformation on the usage environment, working conditions, and fault phenomena of the IC.

· Historical data analysisView relevant failure history records to determine if there are similar issues.

2. Preliminary assessment

· Appearance inspectionUsing a microscope for inspectionOn the surface of the IC, search for signs of physical damage, cracks, burning, etc.

· functional testing: Regarding failureConduct basic functional testing on the IC to confirm its failure nature.

3. Hierarchical analysis

· Graded classificationAccording to the failure modeICs are classified into different categories (such as electrical failure, mechanical failure, thermal failure, etc.).

4. depth analysis

· Material analysisUsing chemical analysis and energy spectrum analysis(EDS and other technologies are used to analyze the composition and characteristics of IC materials.

· Failure Mode AnalysisAdopting Failure Mode and Effects Analysis(Use methods such as FMEA or Fault Tree Analysis (FTA) to analyze failure modes.

· Electrical characteristic testing: MeasurementIdentify abnormal behavior based on the electrical parameters of the IC.

5. Root cause analysis

· Fault Tree Analysis(FTA)Build a fault tree to identify the root cause of failure.

· fishbone diagramOrganize possible causes through fishbone diagram method and conduct systematic analysis.

6. Verification and Confirmation

· Reproduce failureAttempt to reproduce the failure situation under laboratory conditions and verify the analysis results.

· Simulation testing: YesIC undergoes accelerated aging testing to observe its performance under extreme conditions.

7. Report and Suggestions

· Write a failure analysis reportDetailed records of the failure analysis process, identified causes, and suggested improvement measures.

· introduce an improvementBased on the analysis results, suggest improvements in design, materials, or processes.

8. Follow up

· Implement improvementsImplement improvement measures based on suggestions and monitor their effectiveness.

· Continuous improvementRegularly review the failure analysis process, optimize analysis methods and tools.

Through these steps, the failure analysis team can effectively identify and solve the failure problems of integrated circuits, improving the reliability and quality of products.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou