Introduction to Common Welding and Assembly Techniques for Electronic Components

Date:2024-08-07 15:00:00 Views:1897

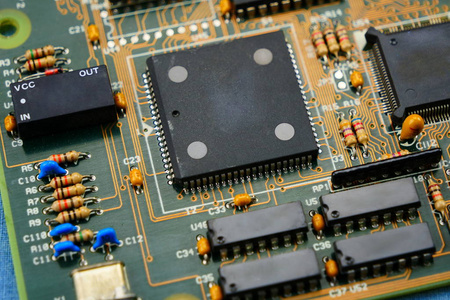

Electronic componentsWelding and assembly are key processes in electronic product manufacturing, involving various technologies and techniques. Here is an introduction to some common welding and assembly techniques:

1. welding technique

a. Manual welding

· describeManual soldering of components using a soldering iron and solder, suitable for small batches and repair work.

· advantageHigh flexibility and suitable for complex layouts.

· shortcomingLow efficiency and quality affected by operator skills.

b. Wave soldering

· describeHeat the solder to a molten state and use peaks toWelding of components at the bottom of PCB.

· advantageSuitable for large-scale production and fast welding speed.

· shortcoming: YesPCB design has requirements and is difficult to handle complex components.

c. Reflow soldering

· describeApply solder paste ontoOn the PCB, place the components and heat them until the solder paste melts, then cool and solidify.

· advantageSuitable for surface mount technology(SMT), Weld evenly.

· shortcomingRequires expensive equipment and high process control requirements.

d. Laser welding

· describeUsing laser beams for welding, suitable for applications that require high precision.

· advantageThe welding heat affected zone is small, suitable for miniature components.

· shortcomingThe equipment cost is high.

2. Assembly technology

a. Surface mount technology(SMT)

· describeDirectly mount the components ontoThe PCB surface is usually mounted using an automatic mounting machine.

· advantageSpace saving, suitable for high-density circuit design.

· shortcomingHigh requirements for welding and cleaning.

b. Through-hole insertion technology(THT)

· describeInsert the pins of the component intoInsert the holes in the PCB and then perform soldering.

· advantageSuitable for high-power components, with a stable structure.

· shortcomingLarge space occupation, not suitable for high-density layout.

c. Mixed assembly

· describe: CombiningSMT and THT technologies are suitable for complex circuits.

· advantageBalancing the advantages of both technologies.

· shortcomingThe process is complex and the production cost is high.

3. welding material

· Solder alloy Common soldering alloys includeSn Pb (lead tin alloy) and Sn Ag Cu (lead-free alloy).

· soldering pasteSolder paste used for reflow soldering, containing solder powder and flux.

· scaling powderUsed to remove oxides and improve welding quality.

4. Welding process control

· temperature controlTemperature control is crucial during the welding process to avoid overheating or insufficient temperature.

· time controlThe welding time should be adjusted according to the components and welding method.

· Cleanliness: EnsureClean the surface of PCB and components to improve soldering quality.

5. Testing and Quality Control

· Visual inspectionVisually inspect the solder joints and component positions.

· X-ray inspectionUsed to inspect the quality and defects of internal welding.

· functional testingEnsure that the assembled circuit board is functioning properly.

6. Common Problems and Solutions

· Poor solder jointsCheck the selection of temperature, time, and materials.

· Short circuit and open circuitEnsure the welding process andThe PCB design is reasonable.

· Component damageControl the welding temperature and time to avoid overheating.

By mastering these welding and assembly techniques, the welding quality and assembly efficiency of electronic components can be improved, ensuring the reliability and performance of products.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou