What are the importance and effective methods of X-ray testing for electronic components?

Date:2024-09-04 11:30:00 Views:1636

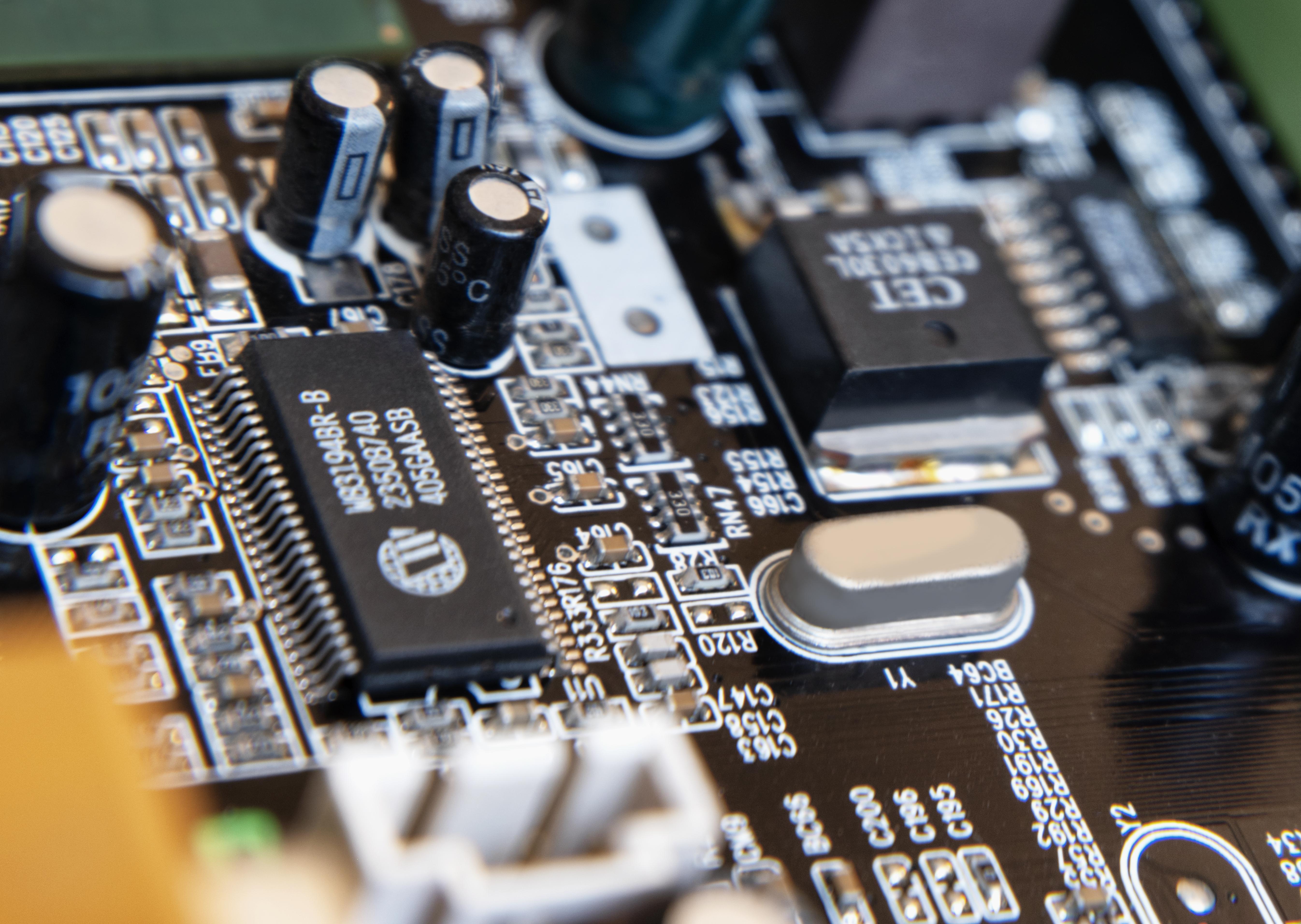

Electronic componentsofXRadiographic inspection plays an important role in modern electronic manufacturing, especially on high-density and high complexity circuit boards. The following is a detailed introduction to its importance and effective methods.

XThe importance of radiographic testing

1. Hidden defect detection:

- XRadiation can penetrate non-metallic materials and detect defects such as bubbles, cracks, and voids in solder joints, internal connections, and packaging, which are difficult to detect in visual inspection.

2. Welding quality assessment:

- adoptXRadiographic testing can evaluate the quality of welded connections, including the shape, size, and integrity of solder joints, to ensure that welding meets standards.

3. Integrity of component packaging:

- Check whether the packaging of the components is complete, ensuring that there is no physical damage or defect affecting their performance.

4. Improve product reliability:

- By early detection of potential defects, the product failure rate can be reduced, and the overall reliability and lifespan of the product can be improved.

5. Compliant with industry standards:

- In some industries such as aviation, healthcare, etc,XRadiographic testing is an important step in ensuring that products meet safety and quality standards.

effectiveXRadiographic testing method

1. real timeXRadiographic imaging:

- Real time imaging technology can quickly obtain internal structural images of circuit boards, suitable for online detection and rapid evaluation.

2. Computerized tomography (CT) scan(CT):

- adoptCTTechnology can obtain three-dimensional images, analyze the internal structure of components in detail, and is suitable for comprehensive inspection of complex circuit boards.

3. Quantitative analysis:

- utilizeXX-ray fluorescence analysis(XRF)Technology can quantitatively analyze the composition of solder to ensure that the welding material meets the requirements.

4. Image processing and analysis software:

- Combined with high-performance image processing software, it can automatically identify defects, evaluate welding quality, and generate inspection reports to improve inspection efficiency.

5. Choose the appropriate oneXRadiation equipment:

- Select suitable products based on their complexity and testing requirementsXRadiation equipment (such as high-resolution)XRadiation machine or portableXX-ray machine).

6. Regular maintenance and calibration:

- ensureXRegular maintenance and calibration of radiation equipment to maintain detection accuracy and reliability.

summary

XRadiographic testing is crucial in the quality control of electronic components, as it can effectively identify hidden defects and improve product reliability. By adopting appropriate testing methods and techniques, efficient and accurate testing can be achieved to ensure that the quality and performance of electronic products meet industry standards.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou