Common semiconductor reliability testing and inspection methods

Date:2024-09-09 15:00:00 Views:2181

semiconductorThe reliability testing and inspection methods are important steps to ensure its stable performance and long lifespan in practical applications. Here are some common semiconductor reliability testing and inspection methods:

1. Accelerated aging test(Accelerated Life Testing)

· methodAccelerate the aging process of semiconductors under high temperature, high humidity, or high voltage conditions to predict their lifespan under normal operating conditions.

· objectiveEvaluate the reliability of the product in long-term use.

2. Thermal cycle test(Thermal Cycling Test)

· methodRepeatedly cycling semiconductor samples between high and low temperatures, usually in-Between 40 ° C and 125 ° C.

· objectiveEvaluate the thermal stress and thermal fatigue performance of materials.

3. Damp heat test(Humidity Testing)

· methodIn high humidity environments (such asTest semiconductors at 85 ° C and 85% relative humidity.

· objectiveEvaluate the performance and reliability of semiconductors in humid environments.

4. Electrical stress testing(Electrical Stress Testing)

· methodOperate semiconductors for extended periods of time under rated current and voltage conditions to evaluate their electrical performance.

· objectiveDetect the influence of current density and voltage on semiconductor performance.

5. Electrostatic discharge(ESD testing

· methodSimulate the effect of electrostatic discharge on semiconductors, usually usingESD testing equipment is used.

· objectiveEvaluate the tolerance of semiconductors to electrostatic discharge.

6. Mechanical stress testing(Mechanical Stress Testing)

· methodTesting semiconductors through mechanical stress such as vibration and impact.

· objectiveEvaluate the reliability of semiconductors in mechanical shock and vibration environments.

7. High acceleration life test(HALT)

· methodRapid testing of semiconductors under extreme conditions such as high temperature, high humidity, high voltage, etc., to identify potential failure modes.

· objectiveAccelerate the identification of design defects and reliability issues.

8. Thermal runaway test(Thermal Runaway Testing)

· methodSimulate the thermal behavior of the chip under overload or short circuit conditions and observe its temperature changes.

· objectiveEvaluate the security of chips under extreme conditions.

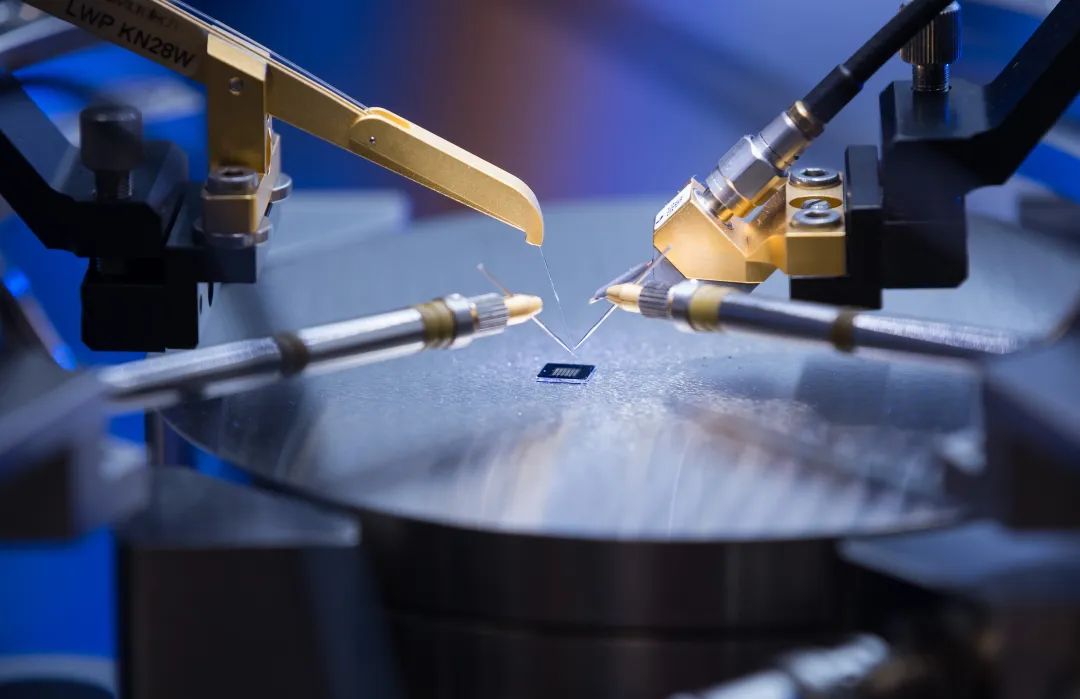

9. X-ray and microscopic examination

· method: UseInspect the internal structure of the chip using X-rays or microscopes to identify potential defects.

· objectiveDetect welding defects, internal structural issues of chips, etc.

10. Failure analysis(Failure Analysis)

· methodDetailed analysis of failed semiconductors to identify the cause of failure, usually combined with techniques such as electron microscopy and optical microscopy.

· objectiveUnderstand failure mechanisms, improve design and manufacturing processes.

11. Life testing(Life Testing)

· methodContinuously operate the semiconductor under standard working conditions and record its performance changes.

· objectiveEvaluate the actual service life of semiconductors.

Through these reliability testing and inspection methods, the performance and reliability of semiconductor devices can be comprehensively evaluated, providing important basis for their performance in practical applications.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou