From "catching up" to "breaking through": the transformation of China's innovation paradigm behind the breakthrough of electron beam lithography machines

Date:2025-09-09 16:13:36 Views:9505

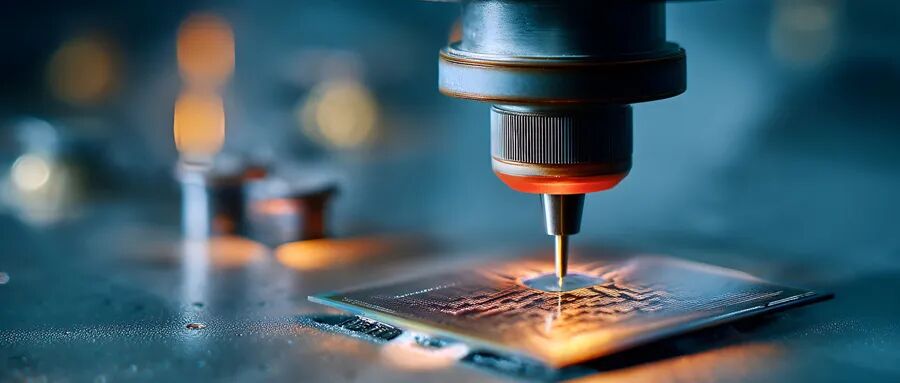

In August, in a laboratory located in the West Hangzhou Science and Technology Innovation Corridor, China's first independently developed 100kV electron beam lithography machine, "Xizhi," was officially put into application testing. This "nano magic pen" that can carve the entire city map on the cross-section of hair strands with a precision of 0.6 nanometers not only marks a historic breakthrough in China's high-end semiconductor equipment field, but also reveals a deeper transformation - China's semiconductor industry is shifting from the traditional innovation paradigm of "introduction, digestion, and absorption" to a new path of "independent innovation+differentiation breakthrough".

After the 2018 US China trade war, ASML's ban on the export of EUV lithography machines from China continued to escalate, causing the Chinese semiconductor industry to face a "bottleneck" crisis. Data shows that by 2024, China's self-sufficiency rate for semiconductor equipment will only be 35%, while the National Integrated Circuit Industry Development Promotion Outline requires it to reach 50% by 2025. This gap forces China to break through the traditional "catching up" path. The third phase of the National Development Fund has a capital scale of over 160 billion yuan, with a focus on investing in bottleneck links such as semiconductor equipment and materials. In the West Hangzhou Science and Technology Innovation Corridor, the government has adopted the "two new integration" model to combine enterprise needs, university research and development, and full process accompanying operations, accelerating the transformation of achievements. This mechanism of "demand driven+government accompanying" has shortened the R&D cycle of "Xizhi" by 30% and reduced costs by 40%.

Unlike ASML's EUV lithography route, "Xizhi" focuses on electron beam direct writing technology, achieving a "bend overtaking" in the fields of quantum chips and third-generation semiconductors. With a precision of 0.6 nanometers, it can accurately etch the quantum bit insulation barrier layer, increasing the yield from 30% to 65%. It also supports the optimization of micro scale platform structures for gallium nitride/silicon carbide devices, resulting in a significant increase in the yield of gallium oxide power devices to 85%. The project is led by the Quantum Research Institute of Zhejiang University, forming an innovative consortium with the University of Science and Technology of China and private enterprises. It relies on the provincial key laboratory to overcome core patents such as electron beam deflection control algorithm and magnetic field shielding technology, and constructs a collaborative innovation model of "enterprise proposal, university unveiling, and government accompanying". This mode has increased the efficiency of technology conversion by 50%, and the localization rate of key equipment has exceeded 40%. Xizhi is not only a device, but also an ecological node. It collaborates with domestic nanoimprint equipment to build a "precision research and development+mass production" technology loop, and cooperates with enterprises such as CSSC Special Gas to promote the localization of supporting materials such as electronic special gas and optical components. Data shows that the project has driven a direct industrial scale of 5 billion yuan and indirect economic benefits exceeding 20 billion yuan.

Although the precision of "Xizhi" surpasses international competitors, its efficiency is only 1/10 of EUV lithography machines. In the future, it is necessary to improve mass production efficiency through technologies such as multi electron beam parallel scanning and AI algorithm optimization, while breaking through the quantum effect error suppression technology caused by electron beam energy fluctuations, and further stabilizing atomic level engraving accuracy. At present, high-purity electronic gases, special silicon wafers and other materials still rely on imports. Taking CSSC Special Gas as an example, it has achieved domestic substitution of gases such as nitrogen trifluoride and tungsten hexafluoride through joint research with the "Xizhi" team, and its global market share has increased from 5% to 10%. In the future, it is necessary to establish a full chain collaborative mechanism of "equipment material design". With the expansion of the application of "Xizhi" in emerging fields such as biochips and photonic chips, China's semiconductor industry is moving from "technological breakthrough" to "standard setting".

The breakthrough of 'Xizhi' is not only a victory for a device, but also a transformation of innovative paradigms. From "market for technology" to "technology for market", from "single point breakthrough" to "system breakthrough", China's semiconductor industry is writing its own innovative narrative. This path may be long, but as the "Xizhi" team said, "This is not an ordinary machine, but a Chinese carving knife that can carve the future in the nano world

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou