How to troubleshoot and deal with the failure of electromagnetic relay?

Date:2021-07-27 09:38:00 Views:5191

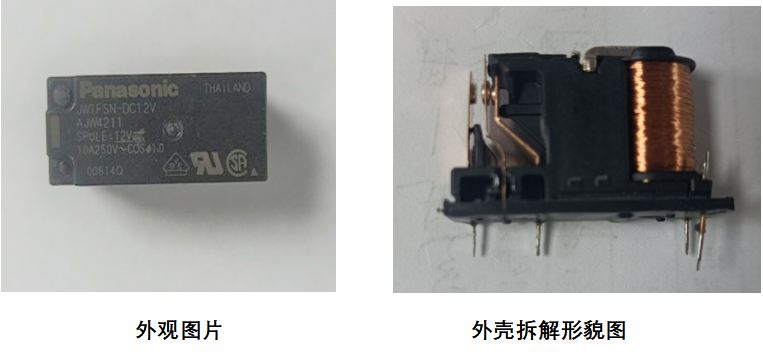

lately,Innovative detection received a batch of fault relays,According to the customer's description,These relaysSome do not work during workshop commissioning, the defect rate is 10%. The appearance of the fault relay is shown in the figure below. It belongs to Panasonic brand and the model is jw1fsn-dc12v ajw4211. It is a common and widely circulated electromagnetic relay product in the market.

For this batch of faulty relays,We disassembled it for internal inspectionTo find out the cause of the fault. Before solving the problem, let's take a look at the basic principle of the relay and understand the common faults of the relay, so as to better understand this case.

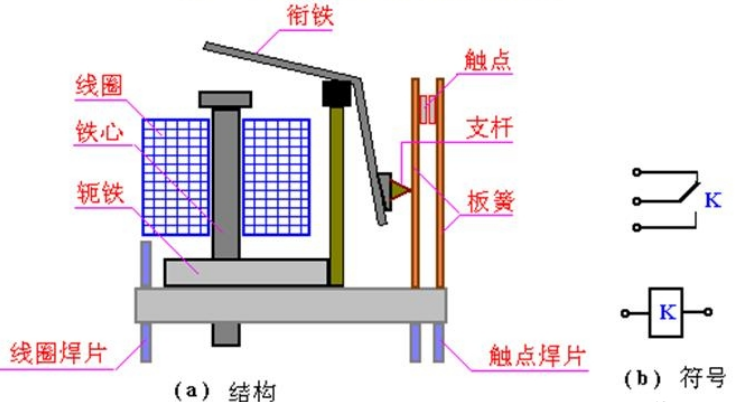

In automatic circuits,The relay plays the role of circuit switching and circuit preservation,The figure above shows a type of relay,Schematic diagram of electromagnetic relay,AlsoWebookIn this caseProblematicrelay。

The electromagnetic relay is mainly composed ofironcore, coil, armature, contact, etc. After the coil is energized,Produce electromagnetic effects,Under the action of electromagnetic force, the armature will overcome the tension of the return spring and attract to the iron core to make the contact get rid of the original position; When the coil is powered off, the electromagnetic attraction disappears, the armature returns to the original position, and the electric shock returns to the original closed state. In application, as long as the circuit to be controlled is connected to the contact, the relay can be used to control the circuitOn and off of。

Electromagnetic relay has classic structure and wide application, and its easy fault has been summarized thoroughly. After long-term use, the electromagnetic relay is prone to loose contacts, ash accumulation, oxidation and other phenomena, resulting in poor contact and relay failure.

in addition to, relay failure will also be caused by over compression of dimension spacing, insufficient screening of product reliability test, insufficient bending resistance of materials and other factors in the process of packaging and assembly.So what is the reason for the failure of this batch of relays we tested this time,Please follow our disassembly。

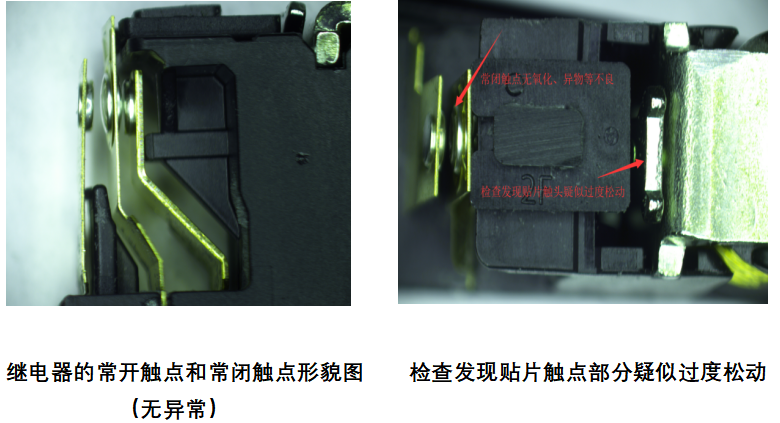

Disassemble as shown in the figure,The coil, electric shock and other key structures of fault relay are all exposed in front of us. After checking all parts, we found that the normally open contact and normally closed contact of the relay were normal, and the patch contact was suspected to be excessively loose. What caused the loosening, we then checked.

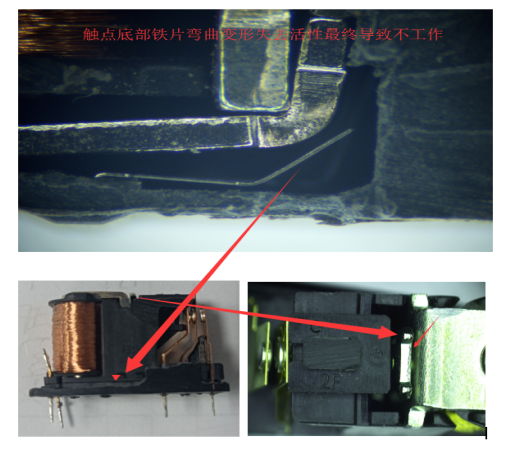

Let's follow the vine and touch the melonObserve the iron plate at the bottom of the auxiliary electric shock of this relayConfirm that the movable iron sheet at the bottom has mechanical deformation, resulting in poor contact of auxiliary contacts, which leads to relay failure. As for the deformation of the bottom iron sheet, it may be caused by corrosion, aging after long-term use, insufficient material strength, oxidation of the bottom patch of the auxiliary contact and other factors, which is more complex.

[Conclusion]:

The customer in this case did not do it for his own special reasonsEDS & material analysis, communicate with the factory site personnel on the use environment, storage, design, etc., check and confirm that there is no error, and finally confirm that the product fault is the application failure caused by insufficient packaging or material strength.

terms of settlement:

Improve the packaging manufacturing process, improve the physical strength of the material, and screen the bad products through the aging life.

[suggestions for core testing]:

Recommend that the customer according to their product needs,Select one with sufficient strengthrelay,And screen out defective products through aging life test,At the same time, improve the product manufacturing process,Avoid damaging key components。 The implementation of the above measures can avoid the adverse impact of failed components on the whole project to the greatest extent.

The above is the interpretation of the failure analysis case of this electromagnetic relay. I hope you can understand the principle and common fault causes of this kind of products. If you find any faulty components during your daily production and trade activities, you are welcome to contact Chuangxin Online Testing Center for testing.

visithttps://www.iclabcn.com, detailedunderstandChuangxin online testing center.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou