Corrosion failure analysis

Date:2021-07-30 17:34:00 Views:3765

catalogue

| What is corrosion analysis? | Type of corrosion failure | Scope of corrosion failure analysis |

| Steps and methods of corrosion failure analysis | Corrosion failure analysis and testing standard | Significance of corrosion failure analysis |

Introduction to corrosion failure items

Corrosion failure corrosion refers to the damage phenomenon caused by chemical or electrochemical reaction on the surface of metal or alloy materials. Although metal corrosion plays a beneficial role in pickling, chemical power supply, electrochemical machining, metallographic etching and so on, it has caused serious losses in the national economy. Because corrosion is the phenomenon that mechanical components lose their original design function, it is called corrosion failure.

Type of corrosion failure

Direct chemical corrosion failure; Electrochemical corrosion failure; Pitting corrosion failure; Local corrosion failure; Intergranular corrosion failure; Selective corrosion failure; Crevice corrosion failure; Biological corrosion failure; Wear corrosion failure; Hydrogen damage failure; Stress corrosion failure, etc.

Corrosion failure analysis scope

Metal corrosion failure analysis, pipe fracture, copper pipe leakage, welding layer cracking, bellows seal failure, spring fracture, quick opening valve cracking, plate corrosion deformation, anti-corrosion coating failure, rolling bearing corrosion failure, etc.

Steps and methods of corrosion failure analysis

1. Field investigation

Protecting all evidence of corrosion failure site is a prerequisite to ensure that corrosion failure analysis can be carried out smoothly and effectively. Evidence collection shall be carried out for the corrosion failure site, and the introduction of relevant equipment principals and operators shall be listened to, the service conditions shall be understood, and the relevant background information shall be collected (such as medium type, temperature, pressure and material of equipment or pipeline, and an appropriate amount of corrosion products shall be collected). The observation and recording can be carried out by means of photography, video recording, recording, drawing and text description. It should be noted that the observation and recording items mainly include:

(1) Name, size, shape, material brand, manufacturer and all manufacturing process history of failed equipment (understand smelting, casting, processing, heat treatment and assembly), operation date, operation records, maintenance records, process flow and operation procedures, etc.

(2) Structural and manufacturing characteristics of failed equipment or components and corrosion appearance of failed components and fragments, such as collection of attachments and corrosion products, observation of all suspicious sundries and traces, etc. In addition, when the corrosion characteristics cannot be directly observed by naked eyes, flaw detection and on-site metallographic observation can be used to further understand and observe the corrosion in detail.

(3) For service conditions and service history (medium environment, temperature, pressure and previous relevant monitoring conditions) of corrosion failed equipment or pipeline, special attention shall be paid to environmental details and abnormal working conditions, such as sudden overload, temperature change, pressure and accidental contact with strong corrosive medium. If necessary, a suitable medium can be selected for laboratory analysis.

(4) Listen to the operators and witnesses to introduce the situation of corrosion failure and its corresponding treatment methods.

(5) Collect past corrosion failures of similar or similar components.

2. Laboratory analysis

Only in rare cases can the cause of corrosion failure be obtained through the analysis of field and background materials. Most failure cases need to further formulate the corrosion failure analysis plan of the laboratory according to the on-site evidence collection and the comprehensive analysis results of background materials, and determine the purpose, content, method and implementation mode of further corrosion failure analysis test. The convincing material evidence on the failed parts and residues is very limited. Therefore, before the test, the test items and sequence, sampling parts, sampling methods and sample quantity shall be fully considered to reasonably determine the location, size, quantity and sampling method of the cut samples. The following analysis methods are usually used:

(1) Macroscopic observation: mainly by means of naked eye or other simple instruments, check whether the surface of corrosion failure parts is smooth, whether there are cracks, whether there are corrosion and corrosion products, and record their size, color, shape and distribution. This method is simple and intuitive, and can simply determine the type of corrosion. The internal surface of equipment or pipeline that cannot be directly seen by the naked eye can be inspected by means of endoscope technology or local damage.

(2) Microstructure analysis: mainly observe the microstructure of corrosion failure parts with metallographic microscope and electron microscope, analyze the influence of microstructure on performance, and check whether the casting, forging, welding and heat treatment processes are appropriate, so as to analyze the causes of corrosion failure from the internal factors of materials.

(3) Chemical composition analysis: spectral method is mainly used to determine whether the materials of corroded parts meet the technical requirements, whether there are useless wrong materials or composition deviation, and trace element analysis or micro area composition analysis can be carried out if necessary.

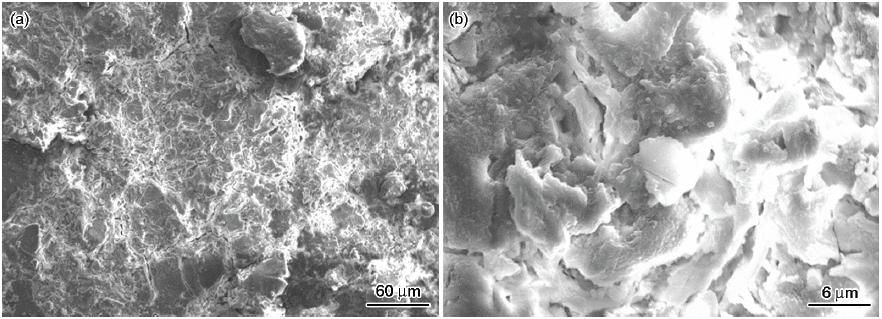

(4) Observation of corrosion morphology: the corrosion morphology truly reflects the whole process of material corrosion. Through the observation of material corrosion surface morphology, we can further understand the corrosion process in detail and speculate the formation process of material surface corrosion characteristics. Therefore, for corrosion failure parts, corrosion morphology analysis is the most important part. Through the analysis of corrosion morphology, we can not only get the information about the service conditions and corrosion failure characteristics of parts, but also understand the properties and conditions near the corrosion failure point, determine the properties and forms of corrosion, and find out the main causes of corrosion failure.

For corrosion morphology analysis, first observe the characteristics of the corrosion surface from various angles with the naked eye or low-power solid microscope and stereo microscope, and roughly estimate the size of corrosion spots or pits on the corrosion surface with the grid, and then deeply observe the representative parts with electron microscope (especially scanning electron microscope) to understand the micro characteristics of the corrosion surface, At the same time, the X-ray energy spectrometer or spectrum analysis (EDX) function attached to the electron microscope can be used to qualitatively and quantitatively analyze the micro area trace elements on the material surface, and analyze the point distribution and surface distribution of elements.

(5) Corrosion product analysis: the observation of surface morphology should be combined with the corresponding corrosion product analysis results in order to more effectively analyze the causes of material failure. For the analysis of corrosion products, chemical burning method, X-ray diffractometer, Auger electron spectroscopy (AES) and photoelectron spectroscopy (XPS) can be used for element or compound analysis.

(6) Medium analysis: conduct chemical analysis on the environmental medium (such as water sample or oil sample) of failed parts obtained on site.

(7) Other test items: when necessary, mechanical property tests of some items can be carried out, including material hardness test and tensile or bending test, to verify whether the mechanical properties of the parts meet the technical requirements. In addition, X-ray diffractometer can be used for qualitative analysis (e.g σ Phase) or quantitative (such as retained austenite content) analysis, stress analysis of parts with complex stress, etc.

(8) Simulation test: for major corrosion failure analysis items, after the failure cause is preliminarily determined, the reproducibility test (simulation test) shall be carried out in time to verify the reliability of the preliminary conclusion. Using the results of medium analysis and material chemical composition analysis, configure the corrosion medium with the same composition in the laboratory, select the same material as the corrosion failure parts, carry out the same heat treatment, and then simulate the field environment (temperature and pressure) for simulated corrosion test to further verify the corrosion formation process and corrosion mechanism. The online bypass test kettle installed on the key corrosion equipment can also be used to monitor the corrosion status of the device (the monitoring time is about 3 to 6 months). The monitoring results can eliminate the short-term effects such as material fluctuation of the device, and more truly reflect the actual corrosion status of the device by selecting test pieces of different materials. If a corrosion failure occurs in a part of the monitoring system, the corrosion failure analysis can be better carried out with the help of long-term monitoring data, and reliable test data can be provided for later material selection.

After completing the above tests, comprehensively analyze the field investigation data and various test results, find out the failure process and determine the cause of failure.

In most cases, there may be many causes of failure, and efforts should be made to distinguish between primary and secondary causes. If there are more than two failure types of a part, the main corrosion failure types and the characterization parameters of the main failure resistance shall be analyzed and found out.

3. Propose remedial or preventive measures

The purpose of corrosion failure analysis is not only to clarify the failure causes, but also to put forward effective remedial and preventive measures. Remedial and preventive measures may involve production process and equipment materials, equipment structure, manufacturing and management. Putting forward and implementing correct measures can reduce the probability of corrosion, greatly reduce the cost of inspection and maintenance, and prolong the operation cycle of equipment or devices. At the same time, rich experience is accumulated from the analysis of a large number of similar and similar failure cases, which is also conducive to the proposal of remedial or preventive measures.

Corrosion failure analysis and testing standard

Aci 423.4r-1998 corrosion and repair of unbonded single strand steel strand

ASTM g161-2000 (2006) guide for failure analysis of corrosion

GB / T 4157-2017 laboratory test method for resistance of metals to sulfide stress cracking and stress corrosion cracking in hydrogen sulfide environment

GB / T 20120.1-2006 corrosion fatigue testing of metals and alloys Part 1: cyclic failure test

ISO 11782-1-1998 corrosion of metals and alloys - corrosion fatigue testing - Part 1: cycle of failure test

Significance of corrosion failure analysis

Failure will occur when the material properties cannot meet the mechanical, chemical, thermal and other external conditions during service (or manufacturing, commissioning, storage and transportation). Corrosion is one of the main failure modes for metal structural materials widely used in petroleum industry. Therefore, the purpose of corrosion failure analysis is not only to judge the nature of corrosion failure and confirm the causes of corrosion failure, but also to actively find effective ways to prevent repeated corrosion failure, prevent the occurrence of major failure accidents and ensure the safe operation of equipment or devices. At the same time, corrosion failure analysis can also provide information, direction, ways and methods for technological development and technological transformation. It is an important scientific information source for macroeconomic and technological decision-making.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou