What are the common failure analysis methods for electronic products?

Date:2021-08-09 15:47:00 Views:3836

Failure analysis is a developing emerging discipline, which has been popularized from military industry to ordinary enterprises in recent years. It is generally an activity to simulate and reproduce the failure phenomenon, find out the cause of failure and dig out the failure mechanism according to the failure mode and phenomenon through analysis and verification. It has strong practical significance in improving product quality, technology development and improvement, product repair and arbitration of failure accidents. The rapid development of electronic component technology and the improvement of reliability have laid the foundation of modern electronic equipment. The fundamental task of component reliability is to improve the reliability of components.

Failure analysis object

1. Various materials and parts (metal, plastic, ceramic, glass, etc.)

2. Electronic components (resistance, capacitance, resistance network, inductance, relay, electrical connector, contactor, etc.)

3. Semiconductor discrete devices (diode, triode, FET, thyristor, crystal oscillator, optocoupler, diode stack, IGBT, etc.)

4. Electromechanical devices (relays, mechanical switches, MEMS)

5. Cables and connectors (aviation connectors, various types of cables)

6. Microprocessor (51 series single chip microcomputer, DSP, SOC, etc.)

7. Programmable logic devices (Gal, pal, ECL, FPGA,, CPLD, EPLD, etc.)

8. Memory (EPROM, SRAM, DRAM, MRAM, DDR, flash, nor flash, NAND flash, FIFO, etc.)

9. AD / DA (DAC7611, max525, ADC0832, ad9750, etc.)

10. General digital circuit (CMOS 4000 series, 54 series, 80 Series)

11. Simulator (operational amplifier, voltage comparator, follower series, voltage controlled oscillator, sample holder, etc.)

12. Microwave devices (frequency multiplier, mixer, receiver, transceiver, up converter, voltage controlled oscillator, amplifier, power divider, coupler, etc.)

13. Power supply (linear voltage regulator, switching power converter, power monitor

14. Power management, led, PWM controller, DC / DC, etc.)

Failure analysis and test items

Morphology analysis technology: stereomicroscope, metallographic microscope, X-ray fluoroscopy, acoustic scanning microscope, scanning electron microscope, transmission electron microscope and focused ion beam

Component detection technology: X-ray energy spectrum EDX, auger energy spectrum AES, secondary ion mass spectrometry Sims, spectrum, chromatography and mass spectrometry

Electrical analysis technology: I-V curve, semiconductor parameters, LCR parameters, integrated circuit parameters, spectrum analysis, ESD parameters, electron probe, mechanical probe, insulation withstand voltage and relay characteristics

Unsealing sample preparation technology: chemical unsealing, mechanical unsealing, plasma etching, reactive ion etching, chemical etching and slicing

Defect location technology: liquid crystal hot spot, infrared thermal image, voltage contrast, light emission micrograph, OBIRCH

Failure analysis related standards

Gjb548b-2005 test methods and procedures for microelectronic devices

Gjb450a General requirements for equipment reliability

Gjb841 fault reporting, analysis and correction system

Gjb536b-2011 quality assurance program for electronic components

QJ3065. 5-98 management requirements for failure analysis of components

GJB 33a-1997 general specification for semiconductor discrete devices

GJB 65b-1999 general specification for electromagnetic relay with reliability index

GJB 597a-1996 general specification for semiconductor integrated circuits

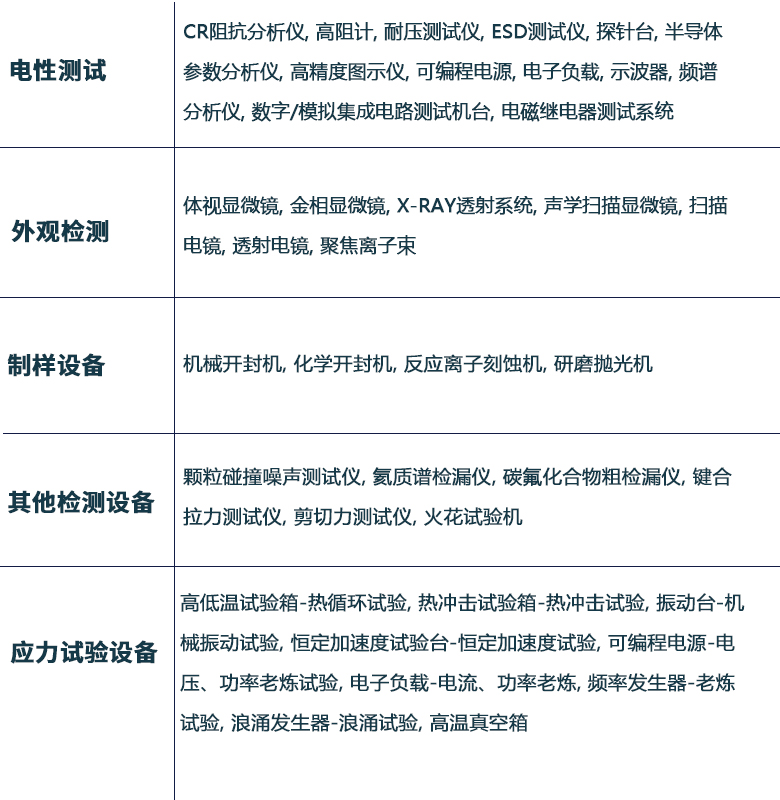

Common equipment for failure analysis

The above is the relevant content of "electronic product failure analysis" brought by the core creation test. Through this article, I hope you have a certain understanding of the content and can be helpful to you. If you like this article, you might as well continue to pay attention to our website, and we will bring more wonderful content later. If you have any needs related to the inspection and testing of electronic products, please call Chuangxin testing, and we will serve you wholeheartedly.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou