Application of machine vision inspection technology in component surface inspection

Date:2021-09-14 17:33:30 Views:2546

With the progress of society and the development of science and technology, automatic detection methods begin to replace the traditional manual methods to improve enterprise production efficiency and product quality. Based on automatic detection, it not only solves the false detection and missing detection caused by the low efficiency and slow speed of manual methods, as well as the subjective constraints of inspectors, but also many systems have realized nearly 100% defect detection. At present, automatic defect detection based on machine vision is widely used. The quality of optical elements mainly depends on the surface quality, and the detection of surface shape deviation, surface roughness and surface defects are the main items to evaluate the surface quality of optical elements. Today we will introduce machine vision detection technology.

As an emerging detection technology that effectively integrates computer vision and image processing technology, machine vision uses digital image as detection means to identify objects through machines instead of human vision system, and then uses image processing methods to extract useful information, such as surface morphology, various parameter values, etc.

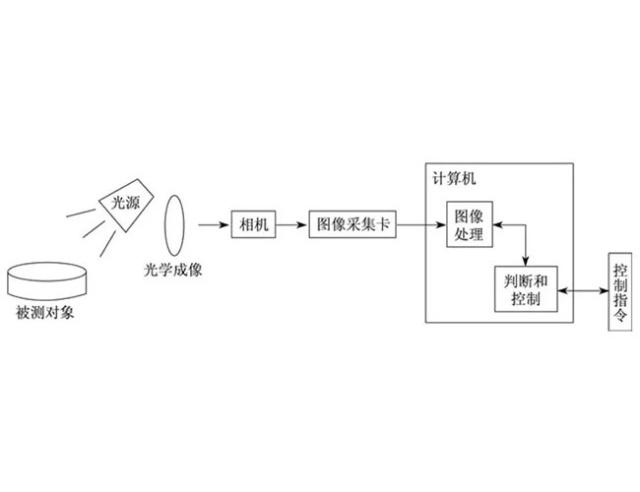

This technology can be applied to control, measurement, detection and other related fields, and can automatically obtain and analyze the images of specific things through the computer. General machine vision system consists of the following units: light source, imaging lens, CCD camera, image processing unit, image processing software and external communication unit. The structural diagram is shown in the figure:

Using machine vision detection technology, it can distinguish the defect image from the background image by using different light sources, different irradiation angles and cameras with different pixels according to different product materials, defect conditions and customer needs, and then use the color, gray, shape and size of the defect image to identify the defect, Through the picture effect, the software is written with different algorithms, and the software is developed in combination with customer needs. It can effectively improve the detection speed and accuracy of the production line, greatly improve the output and quality, reduce the labor cost, and prevent misjudgment caused by human eye fatigue. Making full use of its advantages of non-contact, real-time, flexibility and accuracy, it can be more integrated into the production process or life.

The above is the whole content of the application of machine vision detection technology in component surface detection. Through this article, I hope it can be helpful to you. If you like this article, you might as well continue to pay attention to our website, and we will bring more wonderful content later. If you have any needs related to the inspection and testing of electronic products, please call Chuangxin testing, and we will serve you wholeheartedly.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou