Third party testing organization: failure analysis and testing method and principle of metal materials

Date:2021-09-18 14:54:59 Views:3333

In recent years, as metal materials are more and more widely used in various fields of production and life, the problem of material failure is becoming more and more prominent. Material failure mainly refers to the mechanical component can not fully complete the predetermined function due to the change of size, shape or material organization and performance. The failure modes of metal materials in various engineering applications are mainly composed of fracture, corrosion, wear and deformation. The scope of metal material testing and analysis involves mechanical performance testing, chemical composition analysis, metallographic analysis, precision dimension measurement, nondestructive testing, corrosion resistance test and environmental simulation test of ferrous metals, non-ferrous metals, mechanical equipment and parts.

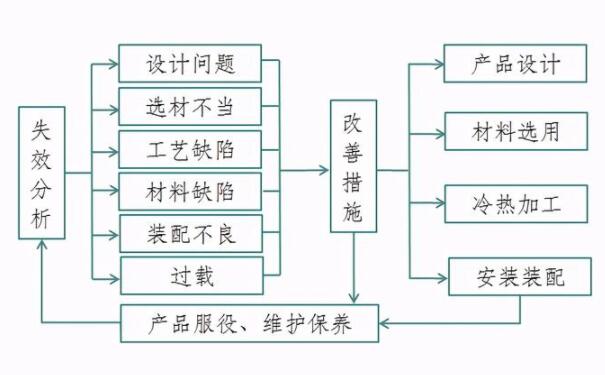

In order to improve the product reputation, we must make the product quality reliable, but it is impossible to require the product to be completely reliable in design, processing and production technology, so it is required to reduce the accident rate of the product as much as possible. For the failure phenomena such as fracture, deformation, wear and corrosion often occur in the use of mechanical products, to find out the causes of failure and put forward improvement measures, we must carry out the study of failure analysis examples.

_20210918145424_519.jpg)

Principle of metal material detection and analysis

The five elements usually refer to manganese, phosphorus, silicon, carbon and sulfur in iron and steel. They are the most important and basic elements in iron and steel. They distinguish the brand and quality of ordinary iron and steel. Their content directly affects the mechanical properties of iron and steel. Common metal element analysis samples include: all kinds of water quality, soil, minerals, waste, textiles, cosmetics, rubber and plastic materials, etc.

Metal element analysis is very common in the fields of metallurgy, casting, machinery and minerals in China. The laboratory is equipped with inductively coupled plasma emission spectrometer (ICP-OES), atomic absorption spectrometer (AAS), X-ray fluorescence spectrometer (XRF), potentiometric titrator, spectrophotometer, nitrogen oxygen meter, carbon sulfur meter and other high-precision chemical detection instruments. The elements that can be analyzed include carbon, sulfur, silicon, manganese, phosphorus, chromium, calcium, nickel, copper, molybdenum, vanadium, titanium, niobium, tantalum, tungsten, cadmium, iron, zinc, magnesium, aluminum, lead, tin, arsenic, antimony, bismuth, nitrogen, hydrogen Oxygen, cobalt, etc.

1、 Test material range

1. Carbon steel, low alloy steel, medium alloy steel, high alloy steel, stainless steel, tool steel, powder metallurgy steel.

2. Iron, aluminum alloy, nickel alloy, titanium alloy, zinc alloy, electroplating material, copper alloy.

3. Steel materials: structural steel, stainless steel, heat-resistant steel, superalloy, precision alloy, chromium, manganese and their alloys.

4. Metals and their alloys: light metals, heavy metals, precious metals, semi metals, rare metals and rare earth metals.

5. Special metal materials: functional alloys, metal matrix composites.

6. Imported metal materials: pig iron, ingot, billet, profile, wire rod, metal products, non-ferrous metals and their products.

Test material analysis items

Routine element analysis: quality (composition analysis), silicon (SI), manganese (MN), phosphorus (P), carbon (c), sulfur (s), nickel (Ni), chromium (CR), copper (Cu), magnesium (mg), calcium (CA), iron (FE), titanium (TI), zinc (Zn), lead (PB), antimony (sb), cadmium (CD), bismuth (BI), arsenic (as), sodium (NA), potassium (k), aluminum (AL), brand determination and moisture content.

Analysis of precious metal elements: silver (Ag), gold (AU), palladium (PD), platinum (PT), rhodium (RH), ruthenium (RU), iridium (IR), osmium (OS).

Metal mechanical strength test: yield strength, elongation, bending test, Rockwell strength, tensile strength, breaking load, stress relaxation test, galvanizing amount test, adhesion test, copper immersion test, high and low temperature tensile test, compression test, shear test and torsion test.

Key analysis items

Chemical properties: corrosion resistance and oxidation resistance.

Physical properties: density, melting point, thermal expansion.

Mechanical properties: tensile strength, compressive strength, flexural strength, shear strength, plasticity, hardness, fatigue, impact toughness, durability, elastic modulus and toughness.

2、 Analysis of metal type and unknown metal composition

1. Stainless steel composition analysis - stainless steel brand identification: 304, 304L, 316 and other stainless steels; Element content detection: Ni, Cr, Mo, Fe, etc.

2. Alloy composition analysis and detection - copper alloy, aluminum alloy, zinc alloy, solder and other alloys: carbon C, nitrogen n, sulfur s, phosphorus P, silicon Si, copper Cu, iron Fe, aluminum Al, tin Sn, molybdenum Mo, nickel Ni, chromium Cr, manganese Mn, titanium Ti, tungsten w, lead Pb, zinc Zn.

3. Conventional metal element analysis and detection, oxygen, nitrogen and hydrogen gas element detection, precious metal detection, heavy metal detection, ROHS detection and metal composition detection of other materials in metal materials.

Material: iron base alloy (carbon steel, stainless steel, tool steel, cast iron, etc.).

Copper base alloy (pure copper, brass, white copper, bronze, etc.).

Aluminum base alloy (variant aluminum, cast aluminum, pure aluminum, etc.).

Magnesium based alloys (magnesium aluminum zinc, magnesium aluminum silicon, etc.).

Nickel base alloy (superalloy, precision alloy, etc.).

Titanium based alloy (pure titanium, t, TC11, etc.), tin based alloy (pure tin, lead tin alloy, lead-free solder, etc.), zinc based alloy (pure zinc, zinc aluminum alloy, etc.).

3、 Failure analysis method of metal materials

In order to obtain better analysis results, failure analysis should not only accurately understand the product use background, but also be supplemented by a series of other inspection methods, such as nondestructive testing, mechanical property test, metallographic inspection, chemical analysis, X-ray analysis, fracture toughness test, electronic energy spectrum analysis, simulation test, etc. Finally, the above analysis and test results and data are comprehensively analyzed, the improvement measures are put forward, and the failure analysis report is written.

(1) Collection of original data

The whole experience of the component before service, the service history of the component and the on-site situation at the time of failure, etc. In addition, samples with analytical value should be selected from scattered failure debris or associated samples.

(2) Selection and storage of failed samples

Failure samples are the first-hand data of failure analysis and the basis of failure analysis. After failure, they should be collected carefully, properly stored and remember to avoid pollution.

(3) Failure sample analysis

In failure accidents, fractures, cracks or other poor appearance are generally formed. Therefore, the analysis of bad parts is the most important analysis means of failure analysis. Fracture analysis includes macro fracture observation and micro fracture analysis.

(4) Other inspection and analysis

In order to better obtain the analysis results, in addition to the observation and analysis of key parts, chemical, mechanical, physical and other experimental analysis must be carried out. Chemical analysis includes routine, local, surface and micro area chemical analysis; Metallographic examination; Structural analysis; Simulation test, such as the simulation of the influence of environmental factors such as temperature and medium concentration on failure.

(5) Comprehensive analysis

When failure analysis reaches a certain stage, it is necessary to conduct a comprehensive analysis and Research on the results and basic test data obtained from various inspections and tests.

4、 Significance of failure analysis of metal materials:

1. Failure analysis can reduce and prevent the occurrence of similar failure phenomena, so as to reduce economic losses and improve product quality.

2. Provide information for enterprise technology development and technological transformation, increase the technical content of enterprise products, and obtain greater economic benefits.

3. Analyze the failure causes of mechanical parts to provide scientific and technical basis for accident liability identification, detection of criminal cases, determination of compensation liability, insurance business, modification of product quality standards, etc.

The above is the relevant content of "metal material failure analysis and test" brought by the core detection. Through this paper, I hope it can be helpful to you. If you like this article, you might as well continue to pay attention to our website, and we will bring more wonderful content later. If you have any needs related to the inspection and testing of electronic products, please call Chuangxin testing, and we will serve you wholeheartedly.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou