SMT component baking standard: how to bake the chip?

Date:2021-10-21 15:46:00 Views:14762

In some factories, there will also be cases where the chip cannot be controlled, resulting in serious chip moisture. At this time, the chip has to be baked and dehumidified. Try to avoid high-temperature baking of the chip. Low temperature and low temperature baking below 100 ℃ can be selected. This can avoid the expansion caused by the sudden vaporization of water. This paper collects and arranges some baking materials of components, hoping that this paper can have great reference value to all readers.

(1) In the sealed state, the price life of components is 12 months.

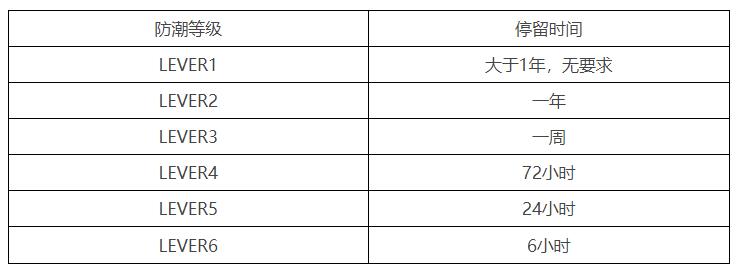

(2) After opening the sealed package, the residence time of the component before passing through the reflow soldering furnace under the environment of less than 30 ℃ and 60% RH is shown in table 2-12.

Residence time before reflow soldering furnace for SMD chips with different moisture-proof grades

(3) After opening the sealed package, if it is not produced, it shall be immediately stored in a drying oven with less than 20% RH.

(4) Conditions requiring baking: (applicable to materials with moisture-proof grade of level2 and above)

① When opening the package, read the humidity indicator card at room temperature, and the humidity is 20%.

② When the package is opened, the retention time exceeds the requirements of the above table and the components have not been pasted and welded.

③ When the package is opened, it is not stored in a drying oven less than 20% RH as required.

④ Components more than one year since the sealing date.

(5) Baking time:

① Bake in a low-temperature oven with a temperature of 40 ℃ + 5 ℃ / - 0 ℃ and a humidity of less than 5% RH for 192 hours.

② Bake in an oven at 125 ℃± 5 ℃ for 24 hours.

SMT chip IC baking standard:

IC baking time (3 hours), rewarming time (2 hours).

1. Device baking in tray

1. Open the outer package of components.

Ⅱ. Check whether each pallet can withstand the baking temperature. Usually, this value should be injected at the end of the pallet. More than 125 ℃ or above is acceptable.

Ⅲ. The required components shall be installed in the oven, and the date, time, part number and position on the shelf shall be recorded in the record book.

Ⅳ. Turn on the power switch and turn on the oven switch.

Ⅴ. After a few seconds, the number in the lower part of the display shall be indicated as "125"; If this value is incorrect, use the up and down arrow keys to correct it.

Ⅵ. The number on the upper part of the display indicates the actual temperature inside the oven. Before putting the device into the oven, if the oven was} cold before, check whether this number is correct; If the oven was previously hot, it shall be maintained at 125 ℃.

Ⅶ. After 24 hours, turn off the power switch.

Ⅷ wait for the oven to cool sufficiently, and then take out the components. The components must be taken out within 1 hour after the oven temperature reaches room temperature, and the date and time of taking out the components shall be recorded according to the corresponding records in the record book.

Ⅸ. Put the baked components into the drying oven, mark the part number accordingly, and indicate that they have been baked.

ESD electrostatic discharge precautions must be observed when putting or removing devices into or out of the oven. ESD electrostatic shoes (or electrostatic overshoes) and grounded wrist strap must be worn.

2. Baking of devices on the material tray

The devices on the tray cannot be baked in the same way as the devices in the tray.

The maximum baking temperature of the tray is 40 ℃, and the duration is 8 days.

Ⅰ. Remove the device from the outer package.

Ⅱ. Put the required devices in the oven and record their date, time, part number and position on the shelf in the record book.

Ⅲ. Turn on the power switch and turn on the oven switch.

Ⅳ. After a few seconds, the number in the lower part of the display shall be indicated as "40"; If this value is incorrect, use the up and down arrow keys to correct it.

Ⅴ. The number on the upper part of the display indicates the actual temperature inside the oven. Before putting the device into the oven, if the oven was cold before, check whether this value increases; If the oven was previously hot, it shall be maintained at the set temperature of 40 ℃.

Ⅵ. After 8 days (192 hours), turn off the power switch and turn off the oven.

Ⅶ. Wait for the oven to cool sufficiently, and then take out the components. Components must be taken out within 1 hour after the oven temperature reaches room temperature. Record the date and time of taking out the components according to the corresponding records in the record book.

Ⅷ. Put the baked devices into the drying oven, properly mark the part number and indicate that they have been baked.

When components are put into or taken out of the oven, ESD electrostatic discharge precautions must be observed. ESD electrostatic shoes (or electrostatic overshoes) and grounded wrist strap must be worn.

The above is the related content of "chip baking" brought by the core creation test. I hope it will be helpful to you. We will bring more wonderful content in the later stage. Our testing services include: electronic component testing and verification, IC true and false identification, product design and material selection, failure analysis, function testing, factory incoming material inspection, tape braiding and other testing items. Warmly welcome to call, we will serve you wholeheartedly.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou