Product reliability analysis: failure judgment method of hast high pressure accelerated aging test

Date:2021-11-03 16:11:00 Views:5670

With the improvement of semiconductor reliability, most semiconductor devices can withstand long-term THB test without failure. Therefore, the test time used to determine the quality of finished products has increased a lot.

Principle:

Under the harsh environment of high temperature, high humidity and bias pressure, the sample accelerates the moisture to pass through the external protective layer, or along the interface between metal and external protective layer, resulting in the failure of the sample.

Standard:

JESD22-110-B

Module design:

nothing

Equipment material:

1. Controlled environment: hast test chamber that needs to ensure pressure, temperature and relative humidity when rising to or falling from a specific test environment.

2. Temperature curve recording: it is necessary to record the temperature curve of each test cycle to ensure that the effectiveness of pressure can be verified;

3. The sample must be located at the place with the minimum temperature gradient, at least 3cm away from the inner wall, and cannot be heated by direct radiation from the heat source;

4. Reduce pollution

5. Remove ionic contamination

6. Deionized water

method:

1. Temperature, relative humidity and time

2. Bias method

a) Reduce power consumption

b) Exchange needle bias as quickly as possible

c) Distribute bit differences on the chip as much as possible

d) Increase the voltage as much as possible within the operational range

e) The following two methods can meet the guidance method:

1) Continuous bias - DC bias needs to be applied all the time

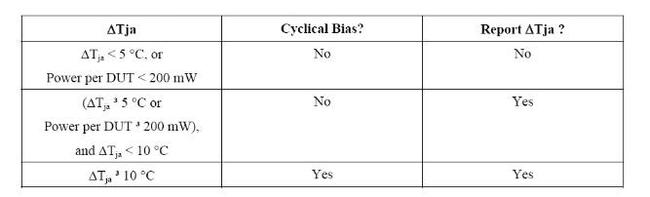

When the failure temperature is ≤ 10 ℃ higher than the ambient temperature of the hast test chamber, or the failure temperature is unknown when the heating loss is less than 200MW, the continuous bias voltage is much stricter than the cyclic bias voltage. When the heating loss reaches 200MW, the failure temperature can be calculated. If the failure temperature exceeds the hast chamber temperature by 5 ℃, it is necessary to record the failure temperature higher than the hast chamber temperature in the results, because the accelerated failure mechanism occurs.

2) Cyclic bias

The DC voltage applied to the sample needs to be interrupted at an appropriate frequency. If the bias setting results in a rise in the temperature of the hast chamber, otia, to 10 ℃, the cyclic bias is more stringent than the continuous bias in order to optimize a specific sample type. Heating caused by energy dissipation will cause the dispersion of moisture and reduce the failure mechanism related to moisture.

When there is no energy dissipation in the sample, the cyclic bias allows moisture to enter when it is interrupted. The 50% cycle is most suitable for most plastic encapsulated circuit boards. For thickness ≥ 2Mn, ≤ 2H is required, while for thickness < 2m, ≤ 30min is required. When the failure temperature exceeds 5 ℃ or more of the hast test chamber, the well-known thermal impedance and dissipation formulas need to be used to calculate the failure temperature.

3. Selection and recording of bias voltage

4. The test sample needs to be exposed to specific temperature, humidity and specific electrical bias environment.It is necessary to avoid overheating, drying or local heating or cooling of the sample.

5. Rise

The time to reach stable temperature and relative humidity shall not exceed 3 hours. Ensure that there is no moisture condensation by ensuring that the temperature in the test chamber always exceeds the temperature of the wet bulb thermometer. The heating rate should not be so fast that the DUT temperature is lower than the wet bulb thermometer temperature. The dry and wet thermometer needs to record the temperature all the time to ensure that the relative humidity is more than 50% at the beginning of main heating. In a dry laboratory, the environment in the hast chamber may be drier than this.

6. Descend

In the first stage, it takes a long time for the sample to drop slightly to a certain standard pressure (wet bulb temperature 104 ℃) to ensure that there are no factors caused by rapid drop. But no more than three hours.

In the second stage, the test chamber needs to discharge pressure from 104 ℃ of wet bulb temperature to room temperature. There is no time limit

The container can also be strongly cooled.

Water condensation is not allowed in the falling part. In order to ensure that the temperature of the test chamber always exceeds the wet bulb thermometer.

When descending, it is necessary to ensure the humidity of the mold plastic packaging hard mold. Therefore, the relative humidity shall not be less than 50% during the descent of the first stage.

Failure determination:

If the limit of parameters is reached, or its functionality cannot be proved under the worst environment, the sample is determined to be invalid in the hast test.

The above is the related content of "judgment failure of hast high pressure accelerated aging test" brought by the core creation test. I hope it will be helpful to you. We will bring more wonderful content in the later stage. Our testing services include: electronic component testing and verification, IC true and false identification, product design and material selection, failure analysis, function testing, factory incoming material inspection, tape braiding and other testing items. Warmly welcome to call, we will serve you wholeheartedly.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou