Professional testing organization: the difference between X-ray testing and slice testing in SMT patch processing

Date:2021-11-10 14:56:03 Views:3998

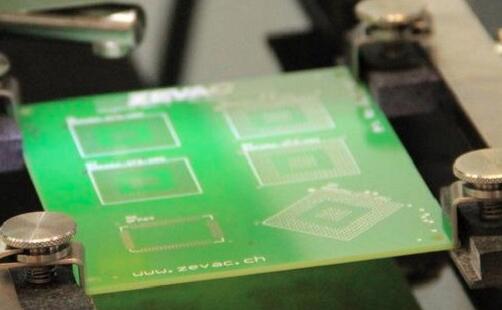

In SMT processing, because many high-precision PCBA circuit boards have a large number of BGA and IC chips, the internal welding status of the core devices of this package can not be seen directly from the surface after welding. Therefore, SMT processing plant must be equipped with relevant testing equipment. The testing equipment for this kind of welding here is mainly X-ray.

So our topic today, what does slice detection do? Its main application link is still on the PCB circuit board, and the quality of the PCB circuit board is detected by slicing. However, in case of major quality abnormalities in SMT patches, it is also necessary to detect the slices of special parts of the whole welded circuit board. Both of them weld the internal situation of the circuit board, but the application links are different.

X-ray is mainly used to generate X-ray by emitting high-energy electrons from the transmitter in the machine for sample penetration imaging. Because the density of each structure in the sample is different, the images presented when X-ray penetrates different objects will have black-and-white gray differences, so as to display the defect position and shape in the sample. X-ray inspection is a non-destructive sample analysis, and other tests can be performed later.

1、 X-ray checks can be applied to:

1. Observation of internal defects of IC packaging parts (broken wiring, holes, cracks and other abnormalities of packaging materials)

2. Observation on welding condition of assembled electronic circuit board (abnormal air welding, pilling, bridge connection, etc.)

3. Analysis on the proportion of pores in welding points

4. Observation of front, side and inclination angles of various materials

5. Observation of filling condition in porous materials

2、 Cross section test

It is mainly for destructive testing of abnormal parts of the sample. First, sample the abnormal parts, then seal and solidify the modified parts with resin, then grind and polish, and finally conduct amplification testing under the microscope.

Compared with the use frequency of X-ray, the use probability of slice test is very low, and we are not very common.

The above is the related content of "the difference between X-ray test and slice test in SMT patch processing" brought by the core test. I hope it can be helpful to you. We will bring more wonderful content later. The company's testing services cover: electronic component testing and verification, IC authenticity identification, product design and material selection, failure analysis, function testing, factory incoming material inspection, tape braiding and other testing items. Welcome to call Chuangxin testing, we will serve you wholeheartedly.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou