What specialty does failure analysis belong to? What is the importance of scientific development?

Date:2022-03-22 14:10:34 Views:3438

Failure analysis is to analyze the causes of mechanical product failure and put forward countermeasures to prevent its technical and management activities. With the rapid development of science and technology, the variety and quantity of mechanical products are increasing. Although the functions of various products are very different, they all have a common attribute - having a certain specified function. For various reasons, mechanical products often lose their original functions. According to the international definition, "the phenomenon that a product loses its specified function is called failure". When and how mechanical products fail is a random event, which people can't predict at all. This paper collects and arranges some relevant materials, hoping to have great reference value to all readers.

What specialty does failure analysis belong to? FA Engineer is called failure analysis engineer in English and failure analysis engineer or failure analysis engineer in Chinese. Its responsibility is mainly to analyze product faults, which can be defective products on the production line or returned products. The responsibility is to find out the source of the fault, and then make corrective suggestions to assist in the implementation and operation of the quality system. FA engineers can also be divided into different majors, such as chemical engineering, mechanical engineering, electronic engineering, system engineering, etc.

Importance of failure analysis to scientific development

(1) The main driving force for the development of science and technology is failure analysis

Since the steam turbine provided the power source for production, various machines and equipment have sprung up. With the emergence of modern industry, productivity has developed rapidly, in which failure analysis plays an important role.

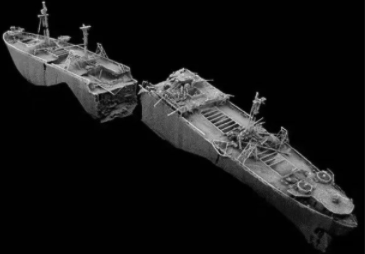

In the Second World War, the United States built 5000 all welded "free wheels", but more than 1000 brittle fracture accidents occurred in use, of which 328 "free wheels" were completely scrapped. These events have attracted great attention from government departments, scientists and engineers. Relevant departments in the United States have organized national forces to conduct failure analysis and research. Through the failure analysis of marine steel plate, the basic theory of low-temperature brittle fracture of steel has been established.

In the 1940s, a Royal Air Force plane crashed, causing a sensation. After more than a year of investigation and evidence collection, Academician Li Xun, a famous Chinese metallurgist and the first director of the Institute of metals of the Chinese Academy of Sciences, put forward the problem of hydrogen embrittlement failure of metals to the academic community for the first time. In addition, the establishment and development of tribology, corrosion, material strength, surface engineering, metallurgy, fractography and other disciplines are closely related to the failure and failure analysis of mechanical products.

Brittle fracture failure of American "free wheel" (simulated recovery diagram)

(2) Failure analysis is an important means to improve product quality

Product quality is not only the pass for enterprises to open the market, but also the most concerned problem of customers. In the strong market competition, enterprises can only survive by quality, reputation and economic benefits. There are many factors affecting product quality. If they are controlled regardless of primary and secondary, it will cause a sharp increase in cost and affect sales. Through failure analysis, we can establish a quality control system economically and effectively, accurately find out the root causes affecting product quality, and take measures in time.

As early as 1936-1945, the American Society for quality management (ASQC) called on American enterprises to pay attention to failure analysis, and required that failure analysis be included in the enterprise quality management system. For a time, enterprises in many European and American countries have made every effort to carry out failure analysis. Some companies are even willing to buy back the failed parts for analysis at a high price, which not only increases the quality of the original products, but also promotes the research and development of new products through the enlightenment brought by the analysis. The serious and responsible work style of enterprises not only does not make them lose customers due to product failure, but also wins the reputation and expands the market.

"Father of quality" J. M. Juran and his quality management manual

(3) Failure analysis can bring huge economic benefits

Failure analysis can not only help enterprises improve product quality, improve market influence and bring economic benefits, but also bring huge economic benefits to the whole national economy. With the booming level of industrial development, the amount spent by the state on product maintenance and replacement every year is also very huge. If the failure analysis is carried out smoothly, the funds for maintenance and replacement of new products will be greatly reduced.

While discussing the economic benefits that failure analysis can bring, enterprises should not only see the economic benefits of immediate, specific, existing cases or products, but also consider the long-term, temporarily insignificant and economic benefits brought by the improvement of product quality of the whole enterprise. Therefore, the failure analysis of mechanical products is an important link to promote the overall optimization of the whole enterprise, occupy the leading position in the industry and promote the development of the whole machinery industry.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou