Reliability failure analysis of connector and connector basic component detection

Date:2022-04-25 14:25:00 Views:2736

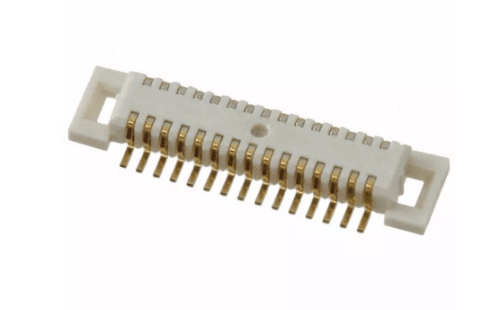

Connectors are also called connectors. Also known as connector and socket in China, it generally refers to electrical connector. That is, a device connecting two active devices to transmit current or signal. The male terminal and the female terminal can transmit information or current through contact, which is also called a connector. Connector reliability is its most important performance. When using connectors, we can record some common factors affecting connector reliability, carefully study and analyze the causes of failure, and put forward some ideas on how to improve connector reliability after finding the causes. Here we have sorted out five common causes of connector failure. Let's have a look.

According to the failure modes and causes of connectors and connectors, the following measures can be taken:

1、 Increase of contact resistance

1. Elastic materials shall be materials with good elasticity, hard stiffness, high strength and stress relaxation resistance.

2. Improve the electroplating quality. The plated metal material requires not only good conductivity, but also wear and corrosion resistance.

3. Improve the machining and assembly accuracy and ensure the correct fit of pins and jacks.

4. Use and operate correctly to avoid forced plugging and straightening.

2、 Open circuit problem

1. Use appropriate crimping tools to avoid damaging the crimping cavity and conductor.

2. Improve the accuracy of base, pin and Jack and the concentricity of pin and Jack.

3. The pin material shall be the material with good mechanical properties and not easy to bend and deform.

3、 Short circuit to ground and insulation resistance drop

1. Insulating materials shall be materials with good environmental stress resistance, moisture-proof performance, excellent dielectric performance and good processing performance.

2. During processing, avoid contamination of insulating materials and potting materials, and prevent inclusion of metal particles or other conductive substances in the materials.

3. For clean production, particles such as conductive metal chips shall be prevented from being left between contacts during processing.

4. Improve the mold and processing technology to avoid bubbles and cracks in insulating parts.

5. Operate and use correctly, and do not insert or unplug forcibly to prevent pin loosening, deformation or damage.

4、 For the problems of increasing plug-in force and decreasing service life

1. The base material shall be the material with good dimensional stability, stiffness and strength.

2. Improve the machining accuracy and consistency of base, pin and Jack.

3. Select high-quality corrosion-resistant coating materials and improve the plating quality.

5、 On the problem of increasing voltage standing wave ratio

1. Cable joints shall be reinforced.

2. Take various measures to eliminate the unstable factors of contact resistance.

3. Pay attention to the alignment of plug and socket contacts and the proper size of male and female contacts during plugging.

4. The medium between inner and outer conductors shall be made of materials with stable performance.

5. Pay attention to the frequency in use, which shall comply with the use regulations.

I hope the above summary can help you. The reasons for the reliability failure of connectors and connectors are different, so the solutions are also different. Whether the insertion force increases, the service life decreases or the contact resistance increases, the problems can be effectively solved by research methods. Shenzhen Chuangxin Online Testing Technology Co., Ltd. is a well-known professional testing organization for electronic components in China. It has three standardized laboratories with an area of more than 1000 square meters. X-ray testing, functional verification of electronic components and parts, and X-ray testing of electronic components and parts, as well as testing of genuine and fake products.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou