Understand the development and implementation steps of failure analysis

Date:2022-04-29 14:20:00 Views:2485

Basic concept of failure analysis: failure analysis is of great significance to the production and use of products. Failure may occur at all stages of the product life cycle, involving product R & D and design, incoming inspection, processing and assembly, test screening, use and other links. Through the analysis of process waste products, early failure, test failure, pilot test failure and field failure samples, confirm the failure mode and analyze the failure mechanism, Clarify the causes of failure, and finally give preventive countermeasures to reduce or avoid the recurrence of failure.

Classification of failures

In terms of failure mode and failure mechanism, the failures we often talk about are generally classified according to the following methods:

1. Fracture failure: fracture failure is often divided into ductile fracture and brittle fracture, and brittle fracture is divided into low-temperature brittle fracture, radiation brittle fracture, hydrogen damage (hydrogen embrittlement), stress corrosion, liquid metal embrittlement, liquid erosion damage, high-temperature stress fracture (i.e. creep fracture) and fatigue fracture.

2. Non fracture failure: it is basically divided into wear failure, corrosion failure and deformation failure. Wear failure generally includes abrasive wear and adhesive wear. Corrosion failure is divided into oxidative corrosion and electrochemical corrosion, and deformation aging is divided into elastic deformation and plastic deformation failure.

3. Composite failure mechanism, as the name suggests, is the failure caused by the comprehensive action of various failure mechanisms. For example, the fracture caused by low cycle fatigue is the combination of ductile fracture and fatigue fracture. Another example is that the failure phenomenon of ablation and thermal corrosion will occur under the combined action of high temperature stress and electrochemical corrosion.

Development process of failure

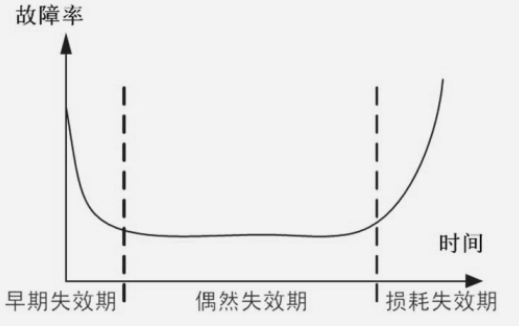

The development process of product failure generally follows the "bathtub curve", which can be divided into three periods:

1. Early failure period refers to the early stage of product use, which leads to obvious failure due to design defects or manufacturing defects.

2. Accidental failure period: under ideal conditions, the product should not have "failure", and the potential defects caused by the environment, operation methods, poor management and other reasons will lead to accidental failure in a certain period, which is called accidental failure period.

3. Wear failure period, which is the curve growth of the product after failure germination to the final failure period, also known as loss failure.

The classification of products according to their failure development process is very useful for reliability engineering.

Implementation steps of failure analysis

1. Protection failure site; The basic principle is to protect all evidence on the scene and maintain its original state.

2. Reconnoiter the failure site and collect background materials; On site reconnaissance and recorded items include but are not limited to the following:

(1) Size, shape and scattering direction of failed parts and fragments;

(2) Metal chips, powder, oxide scale, lubricating residues and all suspicious substances scattered around;

(3) Surface features of failed parts;

(4) Characteristics of equipment or components;

(5) Ambient conditions.

3. Listen to the description of failure by the operator and supporting personnel:

(1) Formulate failure analysis plan;

(2) Implement failure analysis plan;

(3) Comprehensive evaluation of failure analysis results;

(4) Study remedial and preventive measures;

(5) Draft, review and finally put forward failure analysis report.

Failure analysis is the systematic work after the failure of mechanical and electrical products. It can provide technical basis and preconditions for subsequent product development, equipment operation and maintenance, and is the safety guarantee in the production process. Shenzhen Chuang electronic component testing Co., Ltd. has 3 well-known online testing laboratories with an area of more than 1000 square meters. The scope of testing services covers: testing and verification of electronic components, identification of IC authenticity, product design, material selection, failure analysis, function testing, factory incoming material inspection, X-ray testing of components, tape braiding and other testing items.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou