Analysis of failure causes and fault detection methods of common components

Date:2022-07-28 16:00:00 Views:3671

Electronic components often fail in the process of use. Failure means that the circuit may fail, thus affecting the normal operation of the equipment. The failure causes and common faults of common components are analyzed here. Most of the faults in electronic equipment are ultimately caused by the failure of electronic components. If you are familiar with the failure causes of components and locate the failure causes of components in time, you can eliminate the faults in time and make the equipment operate normally.

_20220728144351_924.jpg)

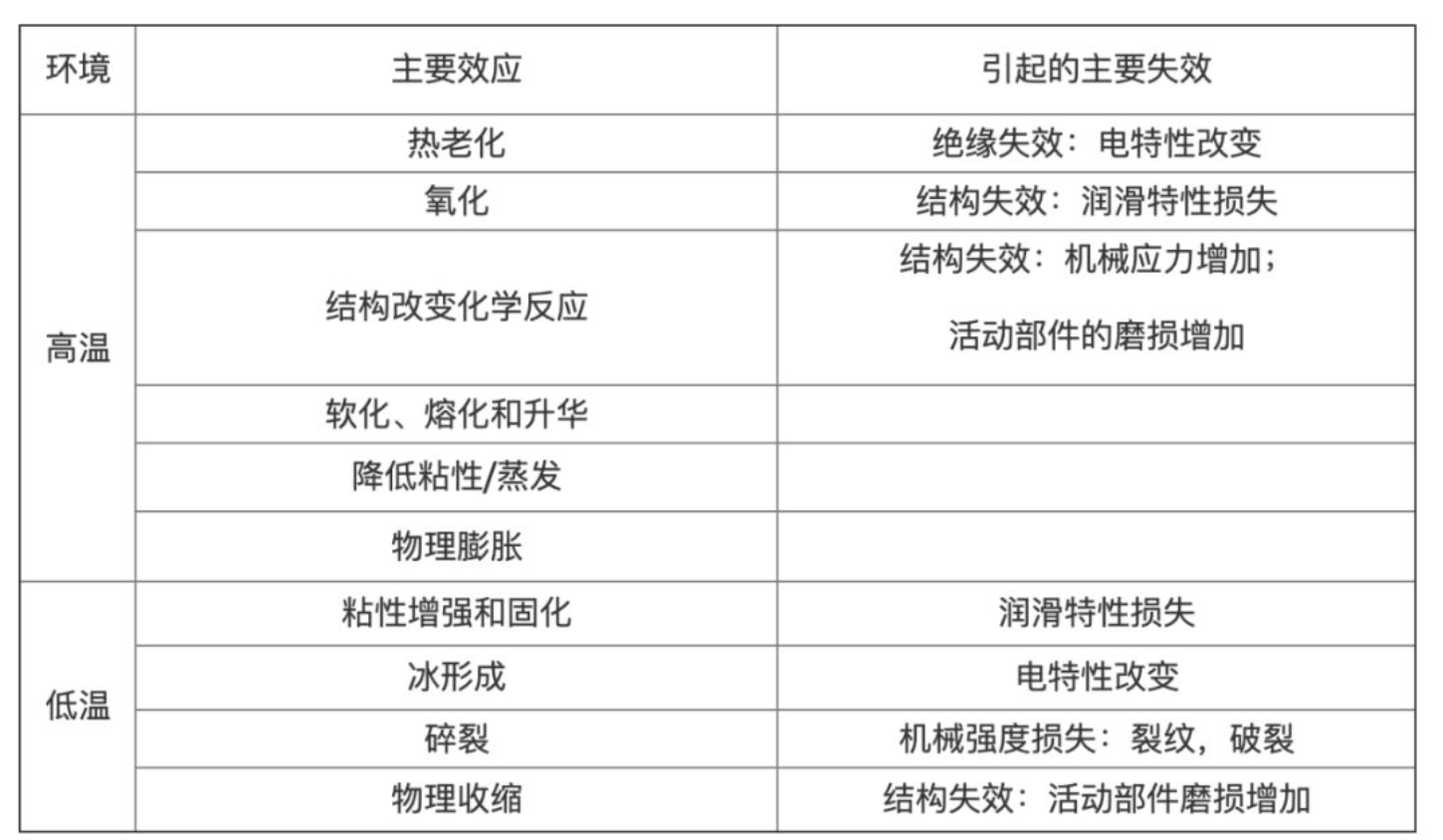

Temperature leads to failure: one of the important factors of component failure is the influence of ambient temperature on components.

Influence of temperature change on semiconductor devices:

Because the forward voltage drop of p-n junction is greatly affected by temperature, the voltage transmission characteristics and anti-interference degree of bipolar semiconductor logic elements (TTL, HTL and other integrated circuits) composed of p-n as the basic unit are also closely related to temperature. When the temperature increases, the forward voltage drop of the p-n junction decreases, and its opening and closing levels will decrease, which makes the low-level anti-interference voltage tolerance of the component smaller with the increase of temperature; The tolerance of high-level anti-interference voltage increases with the increase of temperature, resulting in output level offset, waveform distortion, steady-state imbalance, and even thermal breakdown.

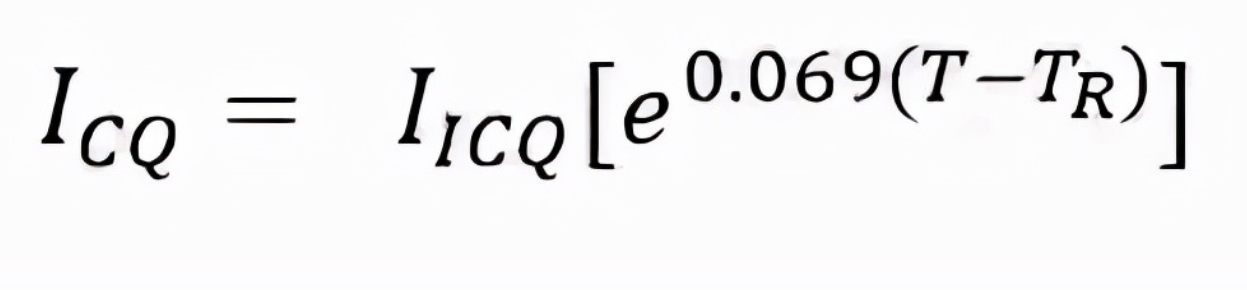

The p-n junction, the basic unit of bipolar semiconductor devices, is very sensitive to temperature changes. When the p-n junction is reverse biased, the reverse leakage current formed by a few carriers is affected by temperature changes, and its relationship is:

Where:

ICQ: reverse leakage current at temperature t0c

Icqr: reverse leakage current at temperature tr ℃

T-tr: absolute value of temperature change

It can be seen from the above formula that ICQ will double for every 10 ℃ increase in temperature. This will cause the working point of the transistor amplifier to drift, the transistor current amplification coefficient to change, the characteristic curve to change, and the dynamic range to become smaller.

The relationship between temperature and allowable power consumption is as follows:

Where:

PCM: maximum allowable power consumption

TA: ambient temperature

TJ: junction temperature of transistor

RJA: thermal resistance between junction and environment

It can be seen from the above formula that the increase of temperature will reduce the maximum allowable power consumption of the transistor.

Effect of temperature change on resistance:

The influence of resistance temperature change is mainly when the temperature rises. An increase in temperature will cause, for example, an increase in the thermal noise of the resistance, a deviation of the resistance from the nominal value, a decrease in the probability of allowable dissipation, etc. For example, when the temperature of RXT series carbon film resistance rises to 100 ℃, the allowable dissipation probability is only 20% of the nominal value.

This characteristic of resistance is not only bad. For example, specially designed resistors: PTC (positive temperature coefficient thermistor) and NTC (negative temperature coefficient thermistor), their resistance values are greatly affected by temperature and can be used as sensors. For PTC, when its temperature rises to a certain threshold, its resistance value will increase sharply. Using this feature, it can be used in the overcurrent protection circuit of the circuit board. When the current passing through it increases to its threshold current due to some fault, the temperature of PTC rises sharply, and at the same time, its resistance value increases, limiting the current passing through it, so as to achieve the protection of the circuit. After troubleshooting, the current through it decreases, the temperature of PTC returns to normal, and its resistance value also returns to its normal value. For NTC, its characteristic is that its resistance value decreases with the increase of temperature.

Influence of temperature change on capacitance:

The change of temperature will cause the change of capacitance to dielectric loss, which will affect its service life. When the temperature rises by 10 ℃, the service life of the capacitor will be reduced by 50%. At the same time, the resistance capacitance time constant will change, and even thermal breakdown will occur due to excessive dielectric loss.

Humidity leads to failure: one of the important factors of component failure is the influence of environmental humidity on components.

When the humidity is too high, when the dust containing acid and alkali falls on the circuit board, it will corrode the solder joint and wiring of components, causing the solder joint to fall off and the joint to break. High humidity is also the main cause of leakage coupling. Low humidity is easy to generate static electricity, so the humidity of the environment should be controlled at a reasonable level.

High voltage leads to failure: one of the important factors of component failure is the influence of high voltage on components.

The important condition to ensure the normal operation of components is to ensure the stability of the voltage applied to the components. Too high voltage will increase the heat loss of components at least, and will cause electrical breakdown of components at most. Take the capacitor for example, its failure rate is proportional to the 5th power of the voltage applied to both ends of the capacitor. For an integrated circuit, a voltage exceeding its maximum allowable voltage will cause direct damage to the device.

Voltage breakdown refers to that electronic devices have the highest withstand voltage value that can be borne. If the allowable value is exceeded, there is a risk of device failure. The forms of failure of active components and passive components are slightly different, but there are also upper voltage limits. Transistor components have withstand voltage values. Exceeding the withstand voltage value will damage the components, such as diodes, capacitors, etc. exceeding the withstand voltage value of the components will lead to their breakdown. If the energy is large, it will lead to thermal breakdown, and the components will be scrapped.

Vibration and impact lead to failure: one of the important factors of component failure is the impact of vibration and impact on components.

Mechanical vibration and impact will accelerate the failure of some internal defective components, resulting in catastrophic failures. Mechanical vibration will also loosen the welding points and crimping points, resulting in poor contact; If the vibration causes undue contact of the conductor, it will have some unexpected consequences.

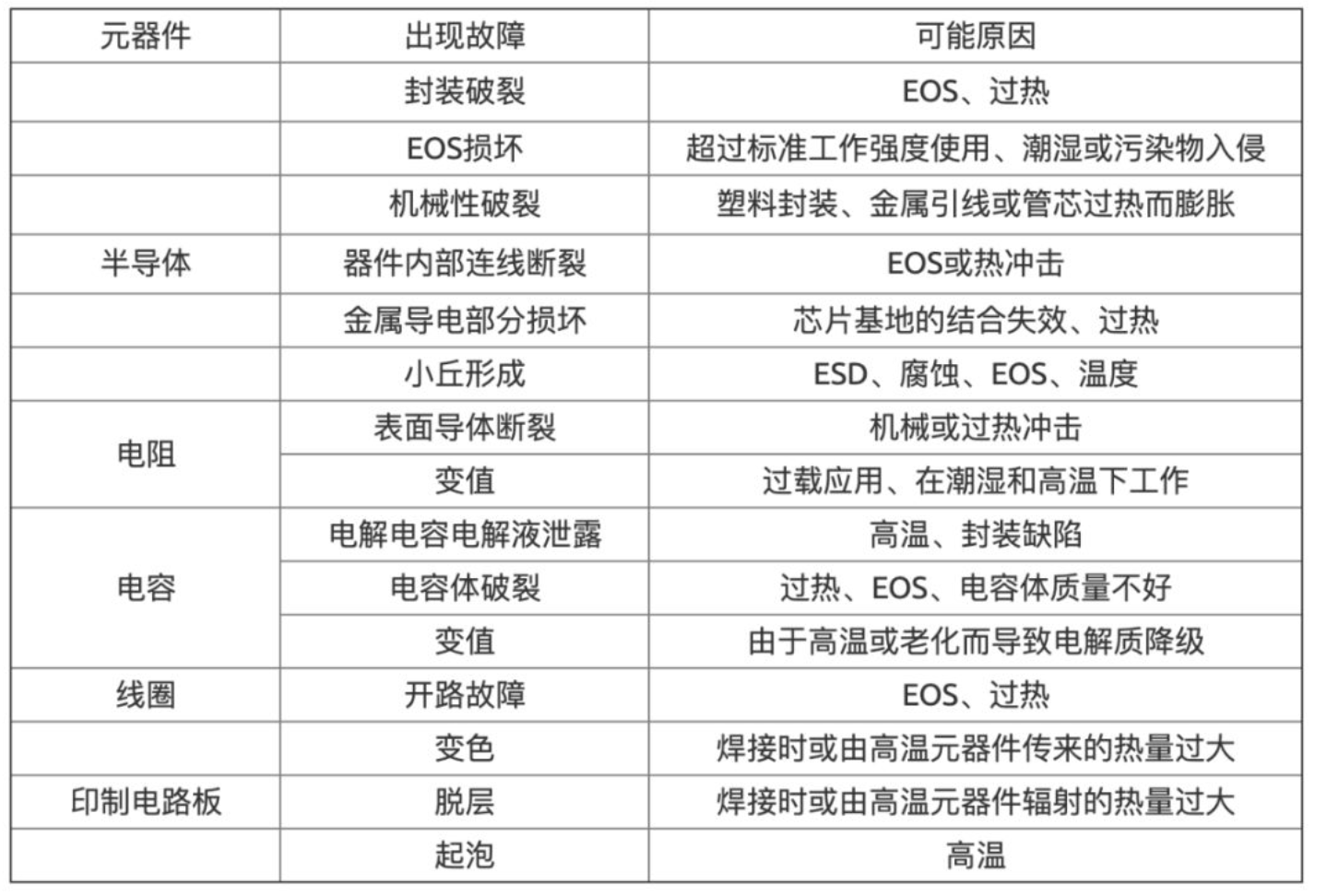

Possible failure modes and failure analysis:

Resistance failure analysis:

The failure mechanism of resistor potentiometer varies according to the type. The main failure modes of non-linear resistors and potentiometers are open circuit, resistance drift, lead mechanical damage and contact damage; The main failure modes of wire wound resistors and potentiometers are open circuit, mechanical damage of leads and contact damage. There are four main categories:

● carbon film resistor. Lead fracture, matrix defect, poor uniformity of film layer, groove defect of film layer, poor contact between film material and lead end, film and matrix pollution, etc.

● metal film resistor. Uneven resistance film, broken resistance film, loose leads, decomposition of resistance film, silver migration, oxide reduction of resistance film, electrostatic charge effect, broken leads, corona discharge, etc.

● wire wound resistor. Poor contact, current corrosion, loose leads, poor wire insulation, solder joint melting, etc.

● variable resistor. Poor contact, poor welding, broken contact * * or lead falling off, impurity pollution, poor epoxy adhesive, shaft inclination, etc.

The resistance is prone to deterioration and open circuit faults. After the resistance is deteriorated, the resistance value tends to drift. Generally, the resistance is not repaired, but directly replaced with a new resistance. Wire wound resistance when the resistance wire is burnt out, in some cases, the burnt out treatment can be used after re welding.

Resistance deterioration is mostly caused by poor heat dissipation, excessive humidity or defects during manufacturing, while burnout is caused by abnormal circuits, such as short circuit, overload and other reasons. There are two common phenomena of resistance burnout. One is that the excessive current causes the resistance to heat, causing the resistance to burn out. At this time, the surface of the resistance can be seen as a burnt paste, which is easy to find. Another case is that the resistance is open circuit or the resistance value becomes larger due to the instantaneous high voltage being added to the resistance. In this case, the resistance surface generally does not change significantly, and the resistance of this fault phenomenon can often be found in high-voltage circuits.

Variable resistors or potentiometers are mainly wired and non wired. Their common failure modes are: parameter drift, open circuit, short circuit, poor contact, high dynamic noise, mechanical damage, etc. However, the actual data show that the main failure modes between laboratory test and field use are quite different. The majority of laboratory failures are parameter drift, while the majority of field failures are poor contact and open circuit.

The failure of poor contact of potentiometer is common in field use. For example, it accounts for 90% in telecommunication equipment and 87% in television, so poor contact is a fatal weak link for potentiometer. The main causes of poor contact are as follows:

● contact pressure is too small, * * stress relaxation, sliding contact deviates from the track or conductive layer, mechanical assembly is improper, or large mechanical load (such as collision, fall, etc.) leads to contact * * deformation, etc.

● the conductive layer or contact track forms various non-conductive films at the contact due to oxidation and pollution.

● the conductive layer or resistance alloy wire is worn or burned, resulting in poor contact of the sliding point.

The open circuit failure of potentiometer is mainly caused by local overheating or mechanical damage. For example, the conductive layer or resistance alloy wire of the potentiometer is oxidized, corroded, polluted, or overloaded due to improper technology (such as uneven winding, uneven thickness of the conductive film, etc.), resulting in local overheating, causing the potentiometer to burn out and open circuit; The sliding contact surface is not smooth, and the contact pressure is too large, which will cause serious wear and tear of the winding and disconnect, resulting in an open circuit; The potentiometer is improperly selected and used, or the failure of electronic equipment endangers the potentiometer, making it work under overload or large load. These will accelerate the damage of potentiometer.

Capacitor failure analysis:

The common fault phenomena of capacitors mainly include breakdown, open circuit, electrical parameter degradation, electrolyte leakage and mechanical damage. The main causes of these failures are as follows:

● breakdown. There are defects, defects, impurities or conductive ions in the medium; Aging of media materials; Electrochemical breakdown of dielectric; Flashover at the edge of the electrode under high humidity or low pressure; Dielectric transient short circuit under mechanical stress; Metal ions migrate to form conductive channels or edge flashover discharges; Dielectric breakdown caused by internal air gap breakdown of dielectric materials; Mechanical damage of medium during manufacturing; Changes in the molecular structure of dielectric materials and the applied voltage higher than the rated value.

● open circuit. Breakdown causes electrode and lead insulation; The anode outgoing foil of electrolytic capacitor is corroded and broken (or mechanically broken); The oxide layer at the contact point between the outgoing line and the electrode causes a low-level open circuit; Poor contact or insulation between outgoing line and electrode; The metal foil from the anode of electrolytic capacitor is corroded, resulting in an open circuit; Drying or freezing of working electrolyte; Instantaneous open circuit between electrolyte and dielectric under mechanical stress.

● electrical parameter degradation. Humidity and dielectric aging and thermal decomposition; Metal ion migration of electrode materials; The existence and change of residual stress; Surface contamination; Self healing effect of metallized electrode of material; Volatilization and thickening of working electrolyte; Electrolytic corrosion or chemical corrosion of electrodes; The contact resistance between lead and electrode increases; Influence of impurities and harmful ions.

Because the actual capacitor works under the comprehensive action of working stress and environmental stress, one or several failure modes and failure mechanisms will be produced, and one failure mode will lead to the occurrence of other failure modes or failure mechanisms. For example, temperature stress can not only promote surface oxidation, accelerate the influence degree of aging, accelerate the degradation of electrical parameters, but also promote the decline of electric field strength and accelerate the early arrival of dielectric breakdown, and the influence degree of these stresses is a function of time. Therefore, the failure mechanism of capacitors is closely related to product types, material types, structural differences, manufacturing processes, environmental conditions, working stress and other factors.

The breakdown fault of capacitor is very easy to find, but it is difficult to determine the specific fault component when there are multiple components in parallel. The open circuit fault of the capacitor can be determined by connecting the capacitor with the same model and capacity in parallel with the detected capacitor and observing whether the circuit function is restored. It is troublesome to check the changes of capacitance electrical parameters, which can generally be carried out according to the following methods.

First, one of the leads of the capacitor should be burned off the circuit board to avoid the influence of surrounding components. Secondly, different methods are used to check the capacitor according to different conditions.

● inspection of electrolytic capacitor. Put the multimeter in the resistance gear, and the range depends on the capacity and withstand voltage of the electrolytic capacitor being measured. Measure the electrolytic capacitor with small capacity and high withstand voltage, and the measuring range should be at R × 10kW gear; Measure the electrolytic capacitor with large capacity and low withstand voltage, and the measuring range should be at R × 1 K W gear. Observe the size of the charging current, the length of the discharge time (the speed at which the needle returns) and the resistance value last indicated by the needle.

The identification methods of electrolytic capacitor quality are as follows:

The charging current is large, the rising speed of the meter needle is fast, the discharge time is long, and the return speed of the meter needle is slow, indicating that the capacity is sufficient.

The charging current is small, the rising speed of the meter needle is slow, the discharge time is short, and the return speed of the meter needle is fast, indicating that the capacity is small and the quality is poor.

If the charging current is zero and the meter needle does not move, it indicates that the electrolytic capacitor has failed.

At the end of the discharge, the resistance value indicated by the meter needle when it returns to the end is large, which indicates that the insulation performance is good and the leakage is small.

At the end of the discharge, the resistance value indicated by the meter needle when it returns to the end is small, indicating poor insulation performance and serious leakage.

● general capacitor inspection with capacity above 1mf. Use multimeter resistance block (R × 10 kW) multiple measurements of the same polarity to check the degree of leakage and whether there is breakdown. Touch the two probes of the multimeter with the two leads of the measured capacitance, and observe whether the probe swings slightly. For capacitance with large capacity, the needle swings obviously; For capacitors with small capacity, the needle swing is not obvious. Then touch the lead of the capacitor with the probe again, three times or four times (the probes are out of tune), and observe whether the needle swings slightly each time. If the needle swings every time it is touched from the second time, it indicates that the capacitor has leakage. If the needle does not move when touching several times in succession, it indicates that the capacitor is good. If the gauge needle swings to the end point at the first collision, it indicates that the capacitor has been broken down. In addition, for capacitors with a capacity of 1mf~20mf, some digital multimeter can measure.

● check capacitors with a capacity of less than 1 MF. The capacitance measuring gear of the digital multimeter can be used to measure the actual value of the capacitor more accurately. If there is no digital multimeter with capacitance measurement function, you can only use ohm block to check whether it has breakdown and short circuit. Use a good capacitor with the same capacity in parallel with the suspected capacitor and check whether it is open circuit.

● accurate measurement of capacitor parameters. LCR bridge can be used to accurately measure the capacity of a single capacitor, and transistor characteristic tester can be used to measure the withstand voltage value.

Failure analysis of inductance and transformer:

Such components include inductance, transformer, oscillation coil, filter coil, etc. Its faults are mostly caused by external reasons. For example, when the load is short circuited, the current flowing through the coil exceeds the rated value, and the transformer temperature rises, causing coil short circuit, open circuit or insulation breakdown. When the ventilation is poor, the temperature is too high or affected with moisture, electric leakage or insulation breakdown will also occur.

For the transformer fault phenomena and causes, the following are common: when the transformer is powered on, if the iron core makes a buzzing sound, the fault cause may be that the iron core is not clamped or the transformer is overloaded; If there is high heat, smoke, scorching smell or fuse burnout, the coil may be short circuited or overloaded.

The following methods are generally adopted for the fault inspection of inductance and transformer components:

● DC resistance measurement method. Use the resistance block of the multimeter to measure the quality of inductive components. When measuring antenna coil and oscillation coil, the measuring range should be set at the minimum resistance (such as R × 1 W gear); When measuring the circumference and output input transformer, the range should be placed at the low barrier (R × 10W or R × 100 W gear), the measured resistance value is compared with the maintenance data or daily accumulated experience data. If it is very close, it means that the tested element is normal; If the resistance value is much smaller than the empirical data, it indicates that the coil has a local short circuit; If the needle indicates zero, the coil is short circuited. It should be noted that the secondary resistance of the oscillation coil, antenna coil and mid circumference is very small, only a few tenths of an ohm. Be particularly careful when reading, and do not misjudge it as a short circuit. Block with high (R × 10kW) when measuring the resistance between the primary coil and the secondary coil, it should be infinite. If there is a certain resistance value between the primary and secondary, it means that there is leakage between the primary and secondary.

● power on inspection method. The power transformer can be checked by energizing to see whether the secondary voltage drops. If the secondary voltage, it is suspected that there is a local short circuit in the secondary (or primary). When the transformer burns rapidly or has a burning smell, smoke and other phenomena after being powered on, it can be judged that there must be a local short circuit in the transformer.

● instrument inspection method. High frequency Q meter can be used to measure the inductance and its Q value, and inductance short-circuit meter can also be used to judge the local short-circuit phenomenon of low-frequency coil. The megger can measure the insulation resistance between the primary and secondary of the power transformer. If the transformer is found to have leakage, it may be caused by poor insulation or moisture. At this time, the transformer can be removed to remove moisture and dry. In addition, all kinds of carbon brushes or copper brushes of the voltage regulating transformer are very easy to wear out in the case of improper maintenance and use. Their fragments and carbon deposits often burn the transformer due to the burning of the coil of the short-circuit part, so pay attention to maintenance at ordinary times.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou