What is the cause of connector failure? Precautions during test

Date:2022-08-02 18:08:39 Views:3601

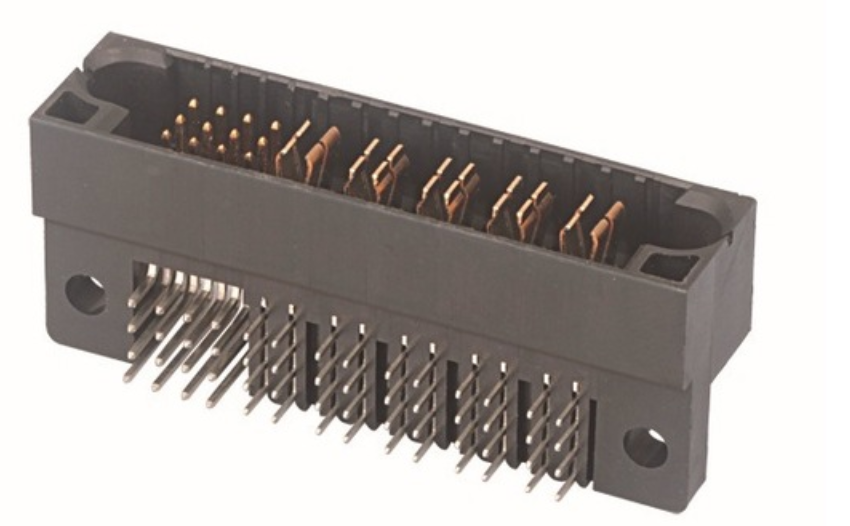

In the process of using connectors, it is inevitable to encounter the failure of connectors. Although each connector has a rated service life, for connectors used in industrial machinery and equipment, some factors will also lead to premature failure of connectors, and even damage to expensive machinery and equipment. This article will introduce the causes of connector connection failure. In addition, this paper will also describe the matters needing attention in the test of board to board connectors.

There are only four reasons for connector failure: degree of wear, improper selection, extreme temperature, and improper design and installation. The following is a detailed introduction:

1. Wear degree of connector

The repeated connection and disconnection of the connector will cause the metal on the contact to wear and corrode when exposed to water, dust, dirt and other irritant elements, which may cause the pin to fail to engage correctly when inserted into the connector housing.

2. Improper connector selection

For example, select special industrial connectors suitable for humid environments. If standard connectors are used instead of IP68 or ip69 grade or sealed design connectors, water will cause connector failure. Choosing a connector that is too small will also reduce efficiency and shorten the service life of the connector.

3. Extreme temperature of connector

If the rated temperature of connectors is not very high or low, they will eventually fail. Because the connector is not suitable for high temperature, the insulation fails and the conductivity reaches the peak. If operating at continuous high temperature, these spikes will raise the temperature, which may lead to corrosion and eventually reduce the contact force. This will affect the electrical signals transmitted through the connector and cable assembly.

Although low temperature will not affect the connector as seriously as high temperature, if you know that your application needs low temperature design, you should consider low temperature design. Exposure to continuous low temperature will cause the tinned connector material to soften and increase the contact resistance. In addition, low temperature will affect other parts of the connector, such as making the plastic shell brittle.

4. Improper connector design and installation

If the application of connectors is affected by impact, vibration and other destructive factors, the safety design that can produce a strong latch is very important. If the installation is not firm, the connector contacts, mating housing and even cables may be damaged. In addition, the connector and cable assembly must have proper stress relief and installation wiring, and the use of guide grooves, cable supports and cable glands helps to ensure the rated life of the connector assembly.

Precautions for board to board connector testing

1. When the board to board connector is working, the current will generate heat at the contact point, resulting in temperature rise, so the working temperature of the board to board connector should be equal to the sum of ambient temperature and contact temperature rise.

2. The insulation performance of the board to board connector will be affected by moisture and moisture intrusion, and the metal parts will also be corroded. Therefore, it is necessary to specify the test conditions, with a relative humidity of 90% - 95% and a temperature of +40 ± 20 ℃.

3. When the board to board connector works in the environment containing salt spray, the contact surface and metal structural parts may produce electrochemical corrosion, which will affect the electrical performance of the board to board connector and cannot be used directly.

The board to board connector is used in pairs with the male and female seats, and the plugging force is an important mechanical property, so the connection and current transmission of the male and female seats are also required to be stable in the test.

Another advantage of the shrapnel microneedle module is that it can use different head types to deal with the test of the male and female seat of the board to board connector. The specific performance is: use the sawtooth shrapnel to contact the male seat of the board connector, and make multi-point contact with the shrapnel on the top of the male seat to maintain the stability of contact; Keep contact with both sides of the board to board connector female base with pointed shrapnel to keep the connection stable for a long time.

The above is the related content of "connector failure cause analysis and test precautions" brought by this core creation test. I hope it can be helpful to you. We will bring more wonderful content later. The company's testing services cover: electronic component testing and verification, IC true and false identification, product design and material selection, failure analysis, function testing, factory incoming material inspection, taping and other testing items. Welcome to call Chuangxin testing, and we will serve you wholeheartedly.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou