Basic knowledge of lead-free soldering Benefits of lead-free process

Date:2022-09-29 14:11:44 Views:2495

Generally speaking, soldering tin is an alloy composed of tin (melting point 232 degrees) and lead (melting point 327 degrees). Soldering tin is an important industrial raw material for wire welding. It is widely used in the electronic industry, common household appliances and so on. It can be said that we cannot live without tin. In order to help you understand, the following contents are organized by the Core Creation Testing Network for your reference.

Solder is mainly divided into three categories: tin wire, tin bar and solder paste.

Solder wire is a linear solder used in standard welding operations, which is often referred to as tin wire. It consists of tin alloy and additives. Solder wire is a tin alloy wire with a certain length and diameter, which can be used in conjunction with electric soldering iron or laser in the welding of electronic original devices.

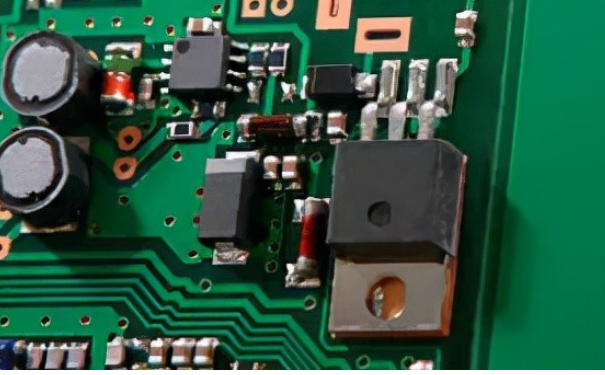

Solder strip is a strip of tin solder, referred to as tin strip, which is used for welding circuit boards.

Solder paste is a new type of welding material. It is a paste mixture formed by mixing solder powder, tin flux, other surfactants, thixotropic agents, etc. It is a gray paste. Solder paste has a certain viscosity at room temperature, which can initially stick electronic components to a given position. At the welding temperature, with the volatilization of solvent and some additives, the components to be soldered will be welded together with the printed circuit pad to form a permanent connection.

There are mainly two types of solder wire, one is lead solder, the other is lead-free solder, and their differences are only the differences in content. Lead solder is an alloy composed of tin (melting point 232 ° C) and lead (melting point 327 ° C). The solder composed of 63% tin and 37% lead is called eutectic solder, and the melting point is 183 ° C; Lead free solder is made of tin copper, tin silver copper and other alloys to meet the ROHS standard proposed by the EU environmental protection requirements, which is more environmentally friendly and safe. It should be pointed out that lead-free does not mean that there is no lead at all. It means that the lead content is relatively low, which can be regarded as lead-free in myopia. The EU defines the lead-free standard as lead content<1000PPm. Considering the possibility of further pollution in welding and subsequent processes, in order to ensure that customers' finished products comply with EU standards, the lead content of general solder wire will be far lower than this standard.

Tin bars can be divided into lead tin bars and lead-free tin bars. Lead free tin bar composition: Sn99.3Cu0.7. The EU standard is less than 1000PPM, the melting point of lead-free tin bar is 223 °, and the English writing of lead-free tin bar is Lead freesolder. Up to now, there is no international general definition, which can be used for reference: the content of solder and lead used for pipe welding is lower than 0.2wt% (America), 0.10.2wt% (Europe).

Lead tin strip: Sn63Pb37. 6337 solder bar melting point: 183 ° 6337 solder bar contains 63 tin, and lead 37 is suitable for wave soldering and hand furnace. After carefully selected electrolytic purification and special refining and melting process, impurities and fine oxides in solder are greatly removed, and trace antioxidant elements are added to 6337 solder bar to ensure excellent quality of solder products. It does not need to pass EU standards, and it is not used in lead-free products. The glossiness is not as bright as lead-free solder bars. 6337 solder rod is a product produced in the lead workshop.

"Lead" is a kind of compound, which not only pollutes water sources, but also causes certain pollution and damage to soil and air. Once the environment is polluted by lead, its governance cycle and funds are very huge, but the harm to human body is more serious. Most of the lead containing solder products sold on the market now will produce a large number of solder slags. On the one hand, the lead containing solder slags not only pollute the soil, but also enter the food chain of animals or humans by infiltrating into the groundwater system, damaging the bone marrow hematopoietic system, nervous system and kidneys in the human body; On the other hand, the production of tin slag is also a loss of resources and property. Now China is accelerating the transformation from lead to lead-free, and lead-free has become an irreversible trend of electronic manufacturing soldering technology.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou