Which is better, selective wave soldering or manual soldering? What are the differences?

Date:2023-01-13 11:40:06 Views:2955

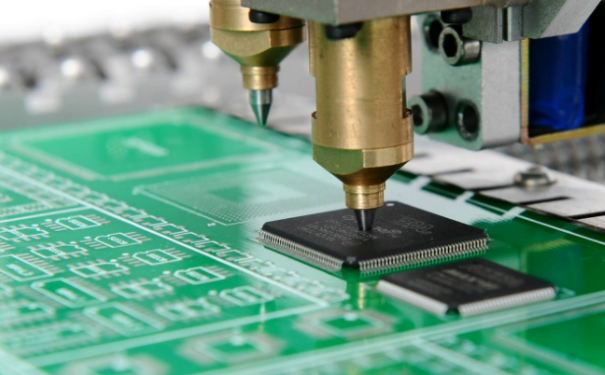

In PCBA processing, there are two processing methods for plug-in materials: selective wave soldering and manual soldering. In the electronic product manufacturing enterprises that pursue efficiency, wave soldering is generally used for most of them. There are also some solder joints that can not be welded by wave soldering, which can only be combined with wave soldering and manual soldering. Which is better, selective wave soldering or manual soldering? What are the differences? To help you understand, the following content is organized by Chuangxin Testing Network for your reference.

1、 Welding quality

From the perspective of welding quality alone, selective wave welding must be better than manual welding. Although the quality of hand welding has been improved based on the application of high-quality intelligent electric soldering iron, there are still some factors that are not easy to control. For example, the control of solder amount and welding wetting angle, the control of welding uniformity, and the requirements for the rate of passing tin of the metallized hole. Especially when the lead wire of the component is gold-plated, it is necessary to remove gold and tin from the parts requiring tin-lead welding before welding, which is a very complicated matter.

There are still human factors and other disadvantages in manual welding, and it is difficult to meet the high quality requirements; For example, with the increase of the density of the circuit board and the increase of the thickness of the circuit board, the welding heat capacity is increased, and the soldering iron welding is easy to cause insufficient heat, resulting in faulty soldering or the climbing height of the through-hole soldering tin does not meet the requirements. If the welding temperature is too high or the welding time is prolonged, it is easy to damage the pcb circuit board and cause the pad to fall off.

2、 Welding efficiency

In the traditional sense, manual soldering requires many people to use point-to-point soldering for PCB. The selective wave welding adopts the industrial batch production mode of pipeline type. The welding nozzles of different specifications can be used for batch welding of drag welding. Generally, the welding efficiency is tens of times higher than that of manual welding.

3、 Welding flexibility

Selective wave soldering is based on the use of programmable and movable small tin cylinder and various flexible welding nozzles, so during welding, certain fixed screws and stiffeners on the B side of PCB can be avoided through program setting to prevent damage caused by contact with high-temperature solder, and customized welding tray is not required; Therefore, it is particularly suitable for a variety of products and small-batch production methods, especially in aerospace and military industries and other industries with very broad application value!

4、 High quality of selective wave soldering

When selective wave soldering is used for welding, the welding parameters of each solder joint can be "customized", and there is sufficient space for process adjustment to adjust the welding conditions of each solder joint, such as the amount of flux spray, welding time, welding wave peak height and wave peak height to appropriate, and the error rate can be significantly reduced or even the zero-defect welding of through-hole components can be realized, compared with manual welding, through-hole reflow welding and traditional wave soldering, The error rate (DPM) of selective wave soldering is the lowest.

From the comparison between selective wave soldering and manual soldering, it is not difficult to find that selective wave soldering has many advantages such as good welding quality, high efficiency, strong flexibility, low error rate, less pollution and diversified welding components. It is the only choice for highly reliable electronic products PCBA welding to replace manual soldering. So today's content will be shared here. If you feel that the content is helpful to you, please pay attention to Chuangxin Testing. We will provide you with more industry information!

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou