Composition, working principle and application field of X-ray detection equipment

Date:2021-05-10 17:29:00 Views:7659

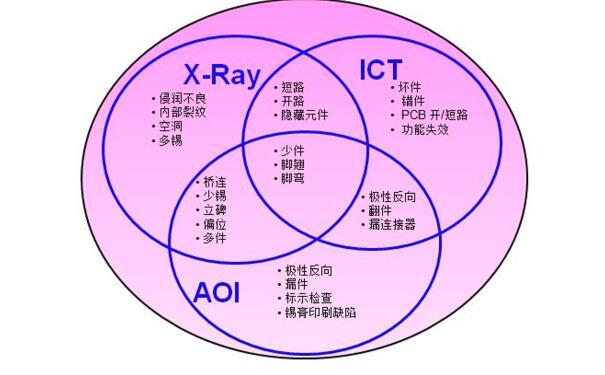

In view of the great changes in modern electronic assembly industry, higher process requirements, more and more attention to product reliability, larger and larger investment scale, and higher requirements for production and testing equipment.The discovery and development of X-ray provides a new way for industrial nondestructive testing, and its emergence has also successfully become a means to realize quality testing, quality control and quality assurance in modern industrial production.Let's understand the composition, structure, working principle and application field of X-ray detection equipment.

In all X-ray testing instrumentsComposition structure:

1. X-ray tube: X-ray tube is the core component of X-ray detector. This X-ray tube mainly produces X-rays. According to the principle of X-rays, it can observe the interior of the detection body through the workpiece.

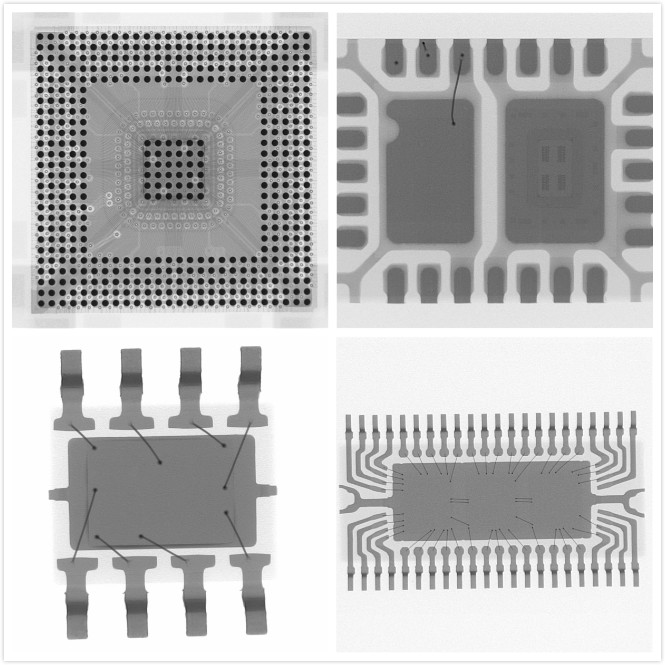

2. Image receiving device: the image receiving device can capture the X-ray passing through the template and convert it into an image that can be presented in front of the user, such as BGA Solder Joints, defects and cracks of castings.

3. Machine architecture: the architecture is the main part supporting the X-ray detector. This part determines the measuring stroke and convenience of X-ray detector.

4. Software and computer control system: software control is the soul of X-ray detector.

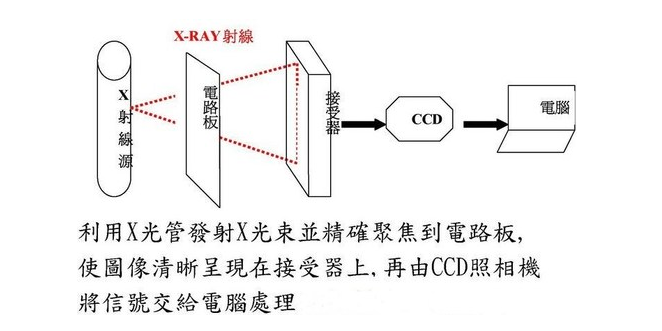

X-ray detection technology has brought new changes to SMT production. First, let's understandX-ray testing principle。

The basic principle of all X-ray detection equipment is X-ray projection microscope. Under the action of high voltage, the X-ray emitting tube generates X-rays, passes through the test sample (such as PCB board, SMT, etc.), and then has different absorption of X-rays according to the density and atomic weight of the sample material, so as to generate an image on the image receiver. The density of the measured workpiece determines the intensity of the X-ray. The higher the density, the deeper the shadow of the material. The closer to the X-ray tube, the larger the shadow, on the contrary, the smaller the shadow, which is the principle of geometric magnification. Of course, not only the density of the workpiece has an impact on the intensity of the X-ray, but also the intensity of the X-ray can be adjusted through the voltage and current of the power supply on the console. The operator can freely adjust the imaging conditions according to the imaging conditions, such as the display size of the image, the brightness and contrast of the image, etc. the operator can also freely adjust and detect the position of the workpiece through the automatic navigation function.

X-ray applications:The discovery and development of X-ray provides a new way for industrial nondestructive testing. Its emergence has also successfully become a means to realize quality testing, quality control and quality assurance in modern industrial production. Today, X-ray nondestructive testing technology is mainly used for SMT, led, BGA, CSP flip chip testing, semiconductor, packaging components, lithium battery industry, electronic components, auto parts, photovoltaic industry, aluminum die casting, molding plastics, ceramic products and other special industries.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou