Common steps for electronic component inspection and screening

Date:2024-07-24 15:00:00 Views:1498

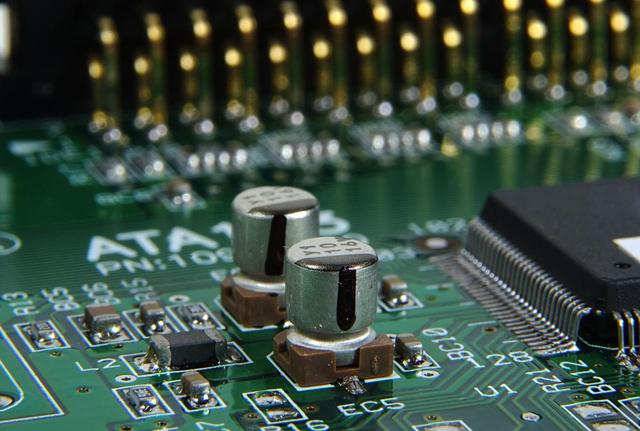

Inspection of electronic componentsScreening is an important process to ensure its quality and performance. Here are some common testing and screening steps:

1. Appearance inspection

Packaging and pins: Check the packaging for damage, scratches, or other physical damages, and the pins for oxidation, bending, or damage.

Identification and Text: Check whether the identification and text on the components are clear and consistent with the description in the specification sheet.

Size and weight: Measure the size and weight of the components to confirm compliance with the specifications.

2. Electrical performance testing

Parameter testing: Use electronic testing equipment (such as multimeters, oscilloscopes, etc.) to test the electrical performance parameters of components, such as resistance, capacitance, voltage, current, etc., to confirm whether they are within the specified range.

Functional testing: for components with specific functions (such asICChips, sensors, etc. require functional testing to confirm their proper functioning.

Environmental adaptability testing: Testing the performance of components in extreme environments such as high temperature, low temperature, high humidity, and low pressure to confirm whether they meet the requirements of the working environment.

3. Long term reliability testing

Lifetime testing: By continuously running components for a long time, observe whether their performance has decreased and evaluate their expected lifespan.

Thermal cycling test: By repeatedly changing the ambient temperature, the thermal stability and heat cycling performance of the components are tested.

4. Safety and environmental testing

Material testing: Check whether the materials of the components comply with environmental regulations, such asROHSandREACH.

Electromagnetic compatibility testing: testing the electromagnetic emission and anti-interference ability of components to confirm whether they meet the requirementsEMCStandard.

5. Other special tests

XRadiographic inspection: For components inside the package that cannot be directly observed, they can be usedXRadiographic inspection of its internal structure and welding quality.

Acoustic microscopy examination: For acoustic sensitive components, acoustic microscopy can be used to examine their internal structure and material quality.

The above steps can help us conduct comprehensive inspection and screening of electronic components to ensure their quality and performance. However, the specific inspection and screening steps may vary depending on the type of component, application requirements, and testing resources.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou