What are the methods for identifying the authenticity of electronic components through appearance?

Date:2024-07-24 14:00:00 Views:1942

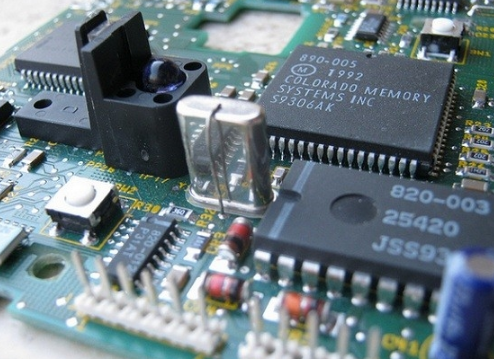

ICAuthenticity verification of chipsIt is an important step to ensure the quality and reliability of electronic components. The following are methods for identifying the authenticity of electronic components through appearance:

Appearance inspection steps

Identification and Text

Printing clarity: genuine productICThe markings and text on the chip are usually very clear, without blurring or ghosting.

Font consistency: Genuine products have consistent font size and style, while counterfeit products may have inconsistent or blurry text.

Packaging and pins

Packaging appearance: Check whether the packaging surface is smooth and flat, without obvious scratches, cracks, or bubbles.

Pin status: The pins should be free of oxidation, bending, damage, or soldering marks. Genuine pins are usually neat and consistent, with a clean surface.

Batch number and date code

Consistency check: The batch number and date code of chips in the same batch should be consistent. If multiple different batches of chips are found in the same packaging, be alert.

Correct format: The batch number and date code should comply with the manufacturer's format specifications. Counterfeit products may have incorrect formats or unreasonable dates.

LOGOAnd brand identity

brandLOGO: Authentic productICBrand of chipLOGOUsually very clear and accurate, without ambiguity or errors.

Check reference image: You can check the chip by comparing official materials or genuine picturesLOGOIs it consistent with the identification.

Packaging type and size

Packaging type: Check if the packaging type is consistent with the product specification, such asDIPTheSOPTheQFPWait.

Dimensional inspection: Use tools such as calipers to measure the chip size and ensure it matches the dimensions in the specification sheet.

manufacturing process

Surface coating: genuine productICThe surface coating of the chip is uniform, with no obvious color difference or gloss difference.

Mold traces: Observe whether the mold traces of the chip are regular, and counterfeit products may have rough and irregular traces.

Use tools to assist in inspection

Magnifying glass or microscope

Magnification inspection: Use a magnifying glass or microscope to examine the details of the chip surface, including textLOGOPin and packaging quality.

High precision weighing

Weight inspection: Different manufacturers use different materials and processes, and the weight of genuine chips is usually the same, which can be preliminarily judged by weighing.

Light inspection

Ultraviolet light: some genuine productsICChips may display specific markings or textures under ultraviolet light, which counterfeit products may not have.

conclusion

By careful inspectionICAppearance, identification, packaging, batch number, and brand of the chipLOGOWait, we can preliminarily identify the authenticity of the components. However, visual inspection can only detect obvious counterfeit and inferior products. For some highly imitated products, it may be necessary to combine electrical performance testingXFurther confirmation of authenticity through radiographic examination. In addition, it is recommended to purchase from reputable suppliers to ensure the reliability of the components.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou