Detailed explanation of IC chip appearance inspection standards and methods and professional component inspection

Date:2021-07-20 13:19:00 Views:9877

After the IC chip packaging process is completed, it must undergo strict testing to ensure the quality of products. Chip appearance testing is an essential and important link, which directly affects the quality of IC products and the smooth progress of subsequent production links. However, in the process of manufacturing products, surface defects are usually inevitable. At present, automatic intelligent detection and identification has been used to replace manual judgment in the detection of many electronic products. While improving efficiency, it can reduce the labor cost of enterprises, keep the machine in a high-precision standard working state for a long time, and effectively avoid the adverse effects caused by manual fatigue, misjudgment and missed judgment.

Common requirements for IC appearance inspection:

Key points: silk screen printing, main body and pin;

Silk screen printing requirements: clear, complete, correct, uniform position, regular font, logo specification, die number and gravure printing of origin, and obvious Pin1;

Main requirements: the size specification, crack, deformity, scratch, glue overflow, deformation and substrate leakage meet the standards;

Pin requirements: deformation, copper leakage, excessive tin, missing, abnormal size, discoloration, etc;

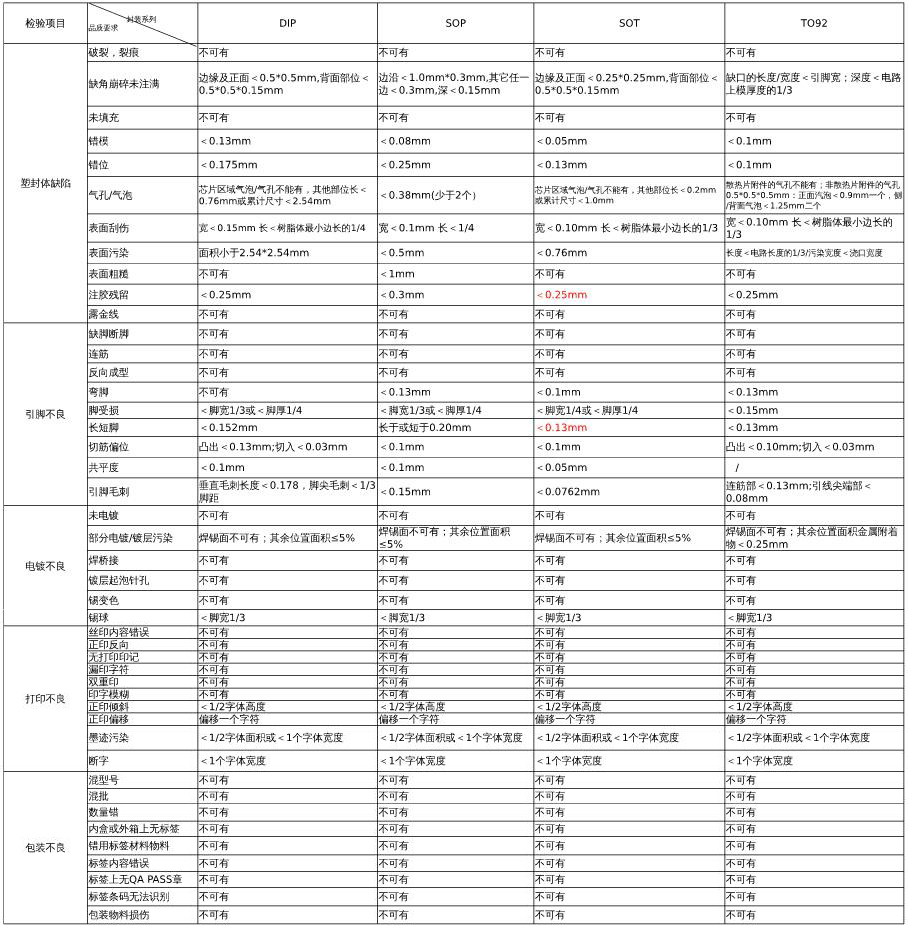

IC appearance inspection standard:

Introduction to operation method of IC chip appearance inspection:

1. It is a traditional manual detection method, which mainly depends on visual inspection, manual detection, low reliability, low detection efficiency, high labor intensity, defect detection and so on. It cannot adapt to mass production and manufacturing

2. It is a detection method based on laser measurement technology, which has high hardware requirements, high cost, high failure rate and difficult maintenance;

3. This method is based on machine vision. Because the hardware of the detection system is easy to integrate and implement, the detection speed is fast, the detection accuracy is high, and the use and maintenance is relatively simple, it is becoming more and more popular in the field of chip appearance detection.

Inspection process of IC chip appearance automatic inspection equipment based on machine vision:

1. The chips are neatly arranged and transported to the front end of the linear track through the vibrating disk, conveyor belt or manipulator

2. The integrated circuit chip is transmitted to the industrial camera through the operation of conveyor belt or glass disk, and then photographed and transmitted to the visualization software processing system

3. Distinguish good products from bad products through visual software operation analysis

4. Pneumatic element, actuator of automatic test equipment. Control the on-off of high-pressure air according to the command of PLC. Blow the tested good and bad products into different receiving devices.

Machine vision detection can carry out high-speed flying photography and maintain efficient operation for a long time. It makes an important contribution to detection, recognition, positioning and so on. Machine vision is generally customized products. Due to different needs of customers and differences in installation environment, technicians will customize their plans. Detection speed, field of vision, placement status of inspected objects, installation environment, etc. are all important factors affecting machine vision selection. The IC pin appearance detection system of machine vision system is one of the typical applications of machine vision instead of manual detection. The detectable contents include: IC pin coplanarity and positive position; Characters on IC; Surface defects such as excessive tin on pins; The detection accuracy is 0.003mm; The detection speed can reach 2-3 times per second.

The above is the whole content of "what is component testing? Standards and methods for IC chip appearance inspection". With the continuous progress of science and technology, machine vision is more and more widely used in the production, manufacturing and quality testing of various industries. The use of machine vision detection system has greatly improved the detection accuracy and accelerated the production efficiency, so it has gradually become an indispensable detection solution in the industry.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou