What is X-ray testing? What are the X-ray testing methods?

Date:2021-10-28 15:36:00 Views:3827

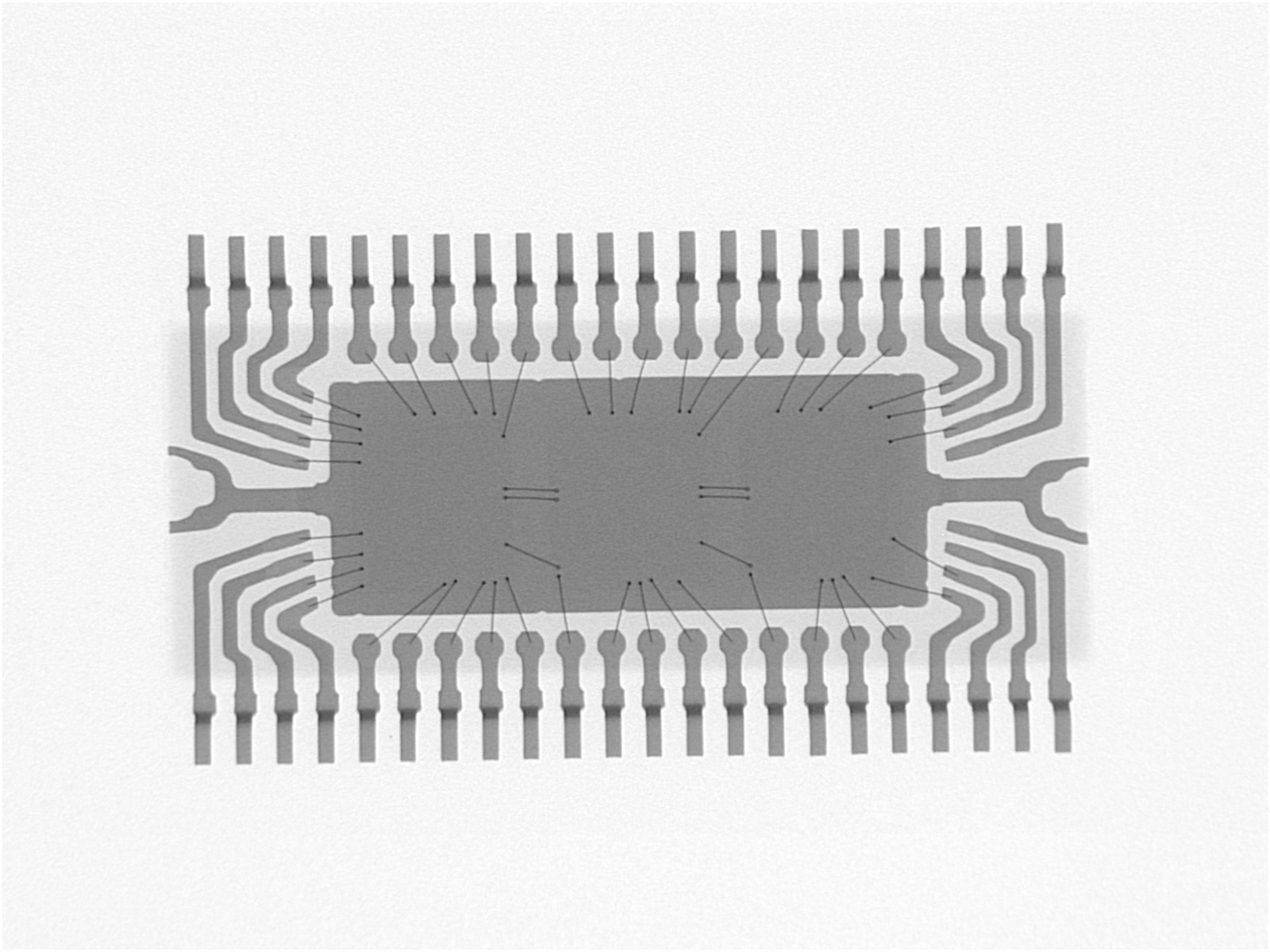

What is X-ray testing? X-ray testing is an experimental technology that uses X-ray technology to observe, study and inspect the microstructure, chemical composition, surface or internal structural defects of materials. Such as X-ray powder diffraction, X-ray fluorescence spectrometry, X-ray photography, X-ray topography, etc. X-ray has been widely used in radiology as one of the five conventional detection methods in industry. This paper collects and arranges some X-ray data, hoping that this paper can have great reference value to all readers.

X-rays can penetrate objects that can not be penetrated by visible light, and have complex physical and chemical interactions with substances. It can ionize atoms and make some substances emit fluorescence. It can also make some substances produce photochemical reactions. If the workpiece has local defects, it will change the attenuation of light by the object and cause the change of transmitted light intensity. In this way, using a certain detection method, we can judge whether the workpiece has defects, as well as the location and size of defects. The penetration ability is related to the wavelength of X-ray, the density and thickness of penetrating material. The shorter the X-ray wavelength, the greater the penetration; The lower the density, the thinner the thickness, and the easier the X-ray penetration. When X-rays are absorbed by a substance, the molecules that make up the substance are broken down into positive and negative ions, which is called ionization. The number of ions is proportional to the amount of X-rays absorbed by the substance. The amount of X-rays can be calculated by measuring the degree of ionization of air or other substances.

The basic principle of X-ray image formation is due to the characteristics of X-ray and the difference of component density and thickness. X-ray inspection technology can be divided into four applications: quality inspection, thickness measurement, article inspection and dynamic research. Quality inspection is widely used in casting, welding process defect detection, industry, lithium battery and electronic semiconductor. Thickness measurement can be used for online, real-time and non-contact thickness measurement. Article inspection can be used for airport, station, customs inspection and determination of structural dimensions. Dynamic research can be used to study dynamic processes, such as trajectory, explosion, nuclear technology and casting technology.

X-ray detection will not damage the inspected object, which is convenient and practical. It can achieve the unique detection effect that can not be achieved by other detection methods. At present, X-ray detection equipment can image in real time, which greatly improves the detection efficiency. Most people talk about the application of X-ray technology in industry, electronics, semiconductors, medical treatment and other fields. In fact, another function is also widely used, that is, foreign object detection. At present, the X-ray foreign body detection equipment on the market is mainly used in the fields of food inspection, industrial use and safety inspection.

X-ray food foreign matter detection

Due to the physical characteristics of X-rays, when the product to be inspected is irradiated with X-rays, the greater the density and atomic number of the substance, the greater the X-ray absorption rate of the substance, and the higher the absorption rate of the substance. X-ray absorption rates of proteins, carbohydrates, fats, moisture and bones in food (calcium) and glass (silica), metals, hair and other components are different, so X-ray photos with different gray levels will be presented.

X-ray foreign matter detection for industrial use

X-ray foreign matter equipment is mainly used to detect metal impurities in products in industry, such as metal and non-metal impurities in aquatic products, health products, additives and condiments; Medical detection of foreign bodies in tablets and powders; Broken needles and nails in clothes, toys, etc.

X-ray examination in safety field

Channel X-ray machines are also widely used for safety inspection. They are similar to foreign object inspection machines. They can centrally check and control knives, prohibited goods, inflammable and explosive materials for personnel at stations and airports. Color images are formed according to organic and inorganic substances. Quickly and accurately help employees conduct hidden danger investigation.

The above is the related content of "X-ray testing" brought by the core test. I hope it can be helpful to you. We will bring more wonderful content later. The company's testing services cover: electronic component testing and verification, IC authenticity identification, product design and material selection, failure analysis, function testing, factory incoming material inspection, tape braiding and other testing items. Welcome to call Chuangxin testing, we will serve you wholeheartedly.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou