Integrated IC visual inspection component appearance defect detection

Date:2022-02-21 14:00:00 Views:3671

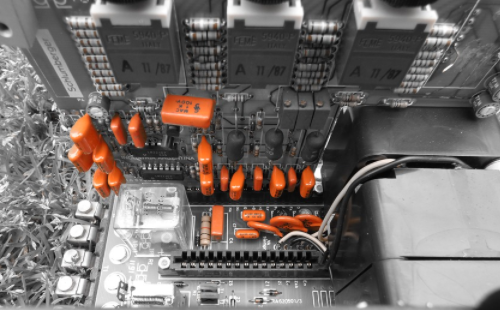

IC chip appearance detection system in the production process of IC integrated chip devices, the appearance quality detection of the chip is an essential link, including the detection items such as pin size, deformity, deflection, uneven spacing and poor flatness of the chip, and the above quality problems will directly affect the quality of circuit products. The automatic detection of appearance defects requires the use of electronic component appearance detection equipment. Then, how to detect the appearance defects of electronic components?

What are the main functions of the appearance inspection system? Visual inspection system mainly includes defect detection, which can detect various defects in products, such as size, location, existence and damage; The measurement of the geometry measurement as the target object; Including identification. Size code, character text, etc.

When identifying and testing electronic components, the following operations shall be carried out:

1. Check that the model, specification, manufacturer and place of origin of components must meet the design requirements, and the outer packaging must be intact.

2. The electrode leads of electronic components shall be free from crimping and bending, and the coating shall be intact and smooth without oxidation and corrosion.

3. Check whether the appearance of electronic components must be intact, whether there are defects such as depression, scratch and crack on the surface, and whether the components with coating on the outside must be free of falling off and scratch.

4. The model and specification marks on electronic components shall be clear and complete, the color code position and color shall meet the standards, and the characters on the integrated circuit shall be carefully checked.

5. The size of components of mechanical structure shall be qualified, the thread shall be flexible and the rotation feel shall be appropriate.

6. Flexible operation and good hand feel of switch components; The connector shall have proper tightness and good contact.

The components in various electronic products have their own characteristics. During inspection, the inspection contents shall be determined according to the specific requirements of each component.

Machine vision inspection has a wide range of applications, such as connector appearance inspection, capacitor appearance inspection, inductor appearance inspection, resistor appearance inspection, pin pin appearance inspection, transformer appearance inspection, wafer size and appearance defect inspection, etc. The product detection through the visual detection system will not affect the efficiency and quality of the detection due to fatigue, and the non-contact detection will not damage the product. While expanding the vision of human eyes, it can also maintain longer working hours.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou