Capacitor failure analysis how to detect the quality of capacitor?

Date:2021-12-06 15:59:37 Views:4658

Electrical appliances operate through the movement of current, while capacitors achieve the effect of capacitance through the voltage of electrical appliances. This type of products often encounter a fatal problem in the process of use, that is, short circuit. Once the product is short circuited, it is nothing more than the failure or damage of the internal capacitance, Therefore, it is very important to analyze and solve the causes of short circuit.

The capacitor enables the motor to start and run by shifting the phase of single-phase current. The motor of single-phase power supply fixed frequency air conditioning compressor adopts single-phase asynchronous motor. According to the working principle of the motor, it is necessary to realize the phase difference of the current in the two sets of motor windings, otherwise it cannot be started.

According to polarity, capacitance is divided into: polar capacitance and non-polar capacitance. The total capacitance of the shunt capacitor is equal to the sum of the capacitances of each capacitor. Namely: C = C1 + C2 + C3. The character symbol of capacitance is: C; Capacitance (UF).

It is worth noting that the larger the capacitance is, the better. If the capacitance is larger, the working current of the motor will increase during operation, and the motor will be easy to burn out. If the capacitance is smaller, the starting torque will become smaller, the motor will be weak, the speed will decrease, and the motor will be difficult or unable to start. Therefore, it is necessary to select the capacitor reasonably.

1、 Failure mode and mechanism of capacitor

The common failure modes of capacitors are: breakdown and short circuit; Fatal failure open circuit; Changes in electrical parameters of fatal failure (including out of tolerance of capacitance, increase of loss tangent, decline of insulation performance or increase of leakage current); Partial function failure and liquid leakage; Partial function failure, lead corrosion or fracture; Fatal failure insulator rupture; Fatal failure insulator surface arcing; There are various reasons for capacitor failure due to partial function failure. The material, structure, manufacturing process, performance and service environment of various capacitors are different, and the failure mechanism is also different.

The main failure mechanism causing capacitor breakdown ① the dielectric material has defects or defects, or contains conductive impurities or conductive particles; ② Electrical aging and thermal aging of dielectrics; ③ Electrochemical reaction inside dielectric; ④ Silver ion migration; ⑤ Dielectric is mechanically damaged during capacitor manufacturing; ⑥ Change of dielectric molecular structure; ⑦ Interelectrode arcing in high humidity or low pressure environment; ⑧ Dielectric transient short circuit under mechanical stress.

Prevention of capacitor overvoltage failure

Capacitors are easy to be broken down under overvoltage, and instantaneous high voltage often occurs in practical application.

Select the capacitor with good transient overvoltage performance and find the original manufacturer to make it safe and reliable. Zhixu JEC electronics specializes in manufacturing and selling capacitors.

2、 How to detect the quality of capacitor?

Test method I:Connect it directly with 220V AC. you can connect one pole first and touch the other capacitor pin with another power line. If there are obvious small sparks when touching, you can be sure that the capacitor is charged, that is, the capacitor is not broken.

testingMethod 2:Pointer multimeter can also measure the capacitance of digital meter. If a pointer multimeter is used, generally use R × 1K gear, connect the probes to the two poles of the capacitor respectively. At this time, the pointer of the multimeter will swing, and then slowly return to the zero position or near the zero position. Such a capacitor is good. The larger the capacity of the capacitor, the longer the charging time, and the slower the pointer swings in the 00 direction. If the pointer does not move after connecting, the displayed resistance value is very few and does not move, it can be sure that it is bad.

testingMethod 3:Detect with a digital multimeter, check with a digital multimeter, turn the digital multimeter to the appropriate resistance gear, and the red probe and black probe contact the two poles of the tested capacitor respectively. At this time, the display value will gradually increase from 0 until the overflow symbol "1" is displayed. If 0 is always displayed, it indicates that there is an internal short circuit in the capacitor. If overflow is always displayed, it may be an open circuit between the internal poles of the capacitor, or the selected resistance gear may not be appropriate.

testingMethod 4:Use a multimeter to measure the capacitance. Adjust the function switch to 20uf or 200uf. The probe is in the middle two holes. The probe is used to measure the two poles of the capacitance respectively. At this time, its capacity will be displayed. If it is a used capacitor, it must be discharged before measurement.

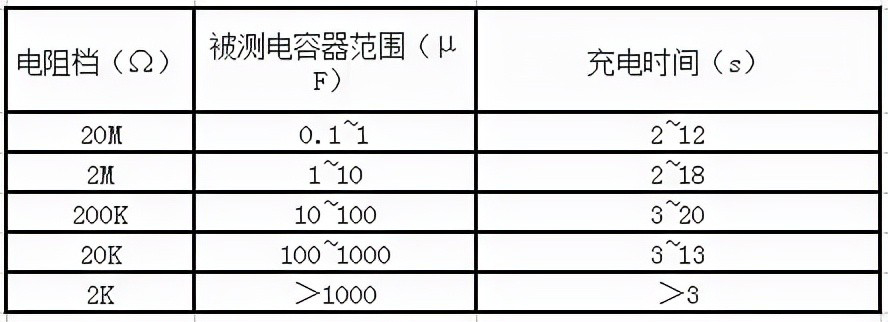

The principle of selecting resistance gear is: when the capacitor is large, low resistance gear shall be selected; If the capacitor capacity is small, high barrier should be selected.

Selection of resistance gear when measuring capacitor:

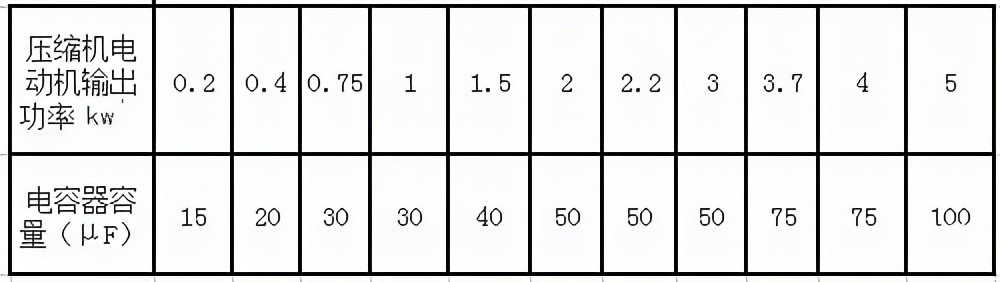

After the capacitor is broken down or open circuit, it cannot be repaired and can only be replaced with a new capacitor of the same model. In order to facilitate selection during repair, the following table lists the selection of capacitor capacity and compressor motor output power for reference.

3、 Common causes of capacitor failure

Common causes of capacitor failure:

1. Capacitor quality problem, withstand voltage can not reach the rated value;

2. Short circuit or grounding between rings (shell);

3. The power supply voltage is too high;

4. Insufficient starting capacitance;

5. Excessive load;

6. Frequent start in a short time;

7. Incomplete separation of centrifugal switch (auxiliary winding) and continuous operation;

8. Damp capacitance, grounding (shell), etc.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou