Component testing knowledge the necessity of electronic product quality inspection

Date:2022-07-06 15:47:40

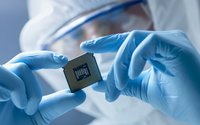

IC chip appearance inspection component appearance defect inspection

Date:2022-07-06 15:44:53

Failure analysis of semiconductor devices and the role of electronic components

Date:2022-07-06 15:43:42

What safety inspection items need to be carried out for electronic products?

Date:2022-07-05 15:10:17

Characteristics analysis and technical difficulties of lead-free welding process

Date:2022-07-05 15:06:24

EU rohs2.0 exemption clause update considerations

Date:2022-07-04 17:12:39

What are the failure modes of metal materials? specialized industrial testing institution

Date:2022-06-30 17:36:31

What are the aspects of formal failure analysis? What's the point?

Date:2022-06-30 17:03:25

Semiconductor shortage led to a new high of chip fraud last year

Date:2022-06-29 16:39:39

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou