What items does the reliability test of electronic components include?

Date:2021-04-28 17:49:28

What tests should be done for the quality of electronic components? X-ray detection is not unknown

Date:2021-04-28 17:26:00

Summary and analysis of five main causes of semiconductor component failure

Date:2021-04-27 16:04:37

Failure analysis and causes of electronic components

Date:2021-04-27 15:35:00

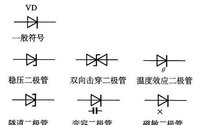

Identification and detection of crystal diodes for electronic components

Date:2021-04-26 17:52:00

It is worth learning from! PCB reliability test method sharing

Date:2021-04-26 16:47:42

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou