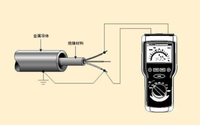

Basic knowledge of nondestructive testing four common methods for weld nondestructive testing

Date:2022-04-20 17:43:09

Specification and standard for nondestructive testing of welds professional testing organization

Date:2022-04-20 17:30:00

How to check whether the power chip is good or bad? IC chip detection method

Date:2022-04-20 15:38:46

Common safety regulations and basic requirements for electronic components

Date:2022-04-20 15:00:00

What are the main electrical tests? Electronic component authenticity detection mechanism

Date:2022-04-19 15:14:09

Since April, such test reports shall be stamped with CMA mark or CNAs approval mark

Date:2022-04-19 15:00:00

Failure analysis of basic knowledge of integrated circuits and explanation of steps

Date:2022-04-19 14:16:00

EMC testing technology and fault diagnosis method

Date:2022-04-19 14:00:00

How to check the quality of components? Sharing skills of detecting circuit board components

Date:2022-04-18 15:17:10

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou