A super comprehensive summary of component failure analysis methods

Date:2021-10-26 17:46:00

How to detect the quality of circuit board electronic components?

Date:2021-10-25 16:14:00

Reliability test: what are the items of product reliability test?

Date:2021-10-25 16:08:00

Importance and purpose of testing and screening of electronic components

Date:2021-10-22 16:39:00

Failure analysis and detection of electronic product materials

Date:2021-10-22 16:12:00

Identification and detection of circuit board components

Date:2021-10-22 15:28:00

Fracture failure analysis: fracture causes and solutions of SMT chip components

Date:2021-10-22 14:35:00

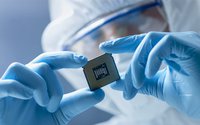

Common test methods for IC detection of semiconductor chips

Date:2021-10-21 18:15:03

Purpose of chip baking: under what circumstances does BGA chip need to be baked?

Date:2021-10-21 17:26:00

What is the function of IC chip baking? What are the requirements?

Date:2021-10-21 16:56:00

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou