What is an electrical performance test? What are the important electrical performance test items?

Date:2021-11-02 14:39:25

Voltage withstand test - electrical performance test

Date:2021-11-01 18:26:32

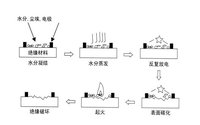

Leakage tracking (CTI) - electrical performance test

Date:2021-10-29 17:41:12

Insulation test - electrical performance test

Date:2021-10-29 17:24:00

Grounding resistance test - electrical performance test

Date:2021-10-29 17:05:00

Contact resistance test - electrical performance test

Date:2021-10-29 15:23:00

Introduction to application and standard of X-ray testing technology

Date:2021-10-28 16:33:00

What is X-ray testing? What are the X-ray testing methods?

Date:2021-10-28 15:36:00

How to inspect and screen electronic components

Date:2021-10-27 18:05:49

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou