Scratch test - Reliability Test

Date:2021-11-04 17:45:51

Constant temperature and humidity test - Reliability Test

Date:2021-11-04 17:22:00

Dust proof test - Reliability Test

Date:2021-11-03 17:26:00

Cross cut test - Reliability Test

Date:2021-11-03 16:52:00

Accelerated aging test (HAST) - Reliability Test

Date:2021-11-03 16:23:00

Product reliability analysis: failure judgment method of hast high pressure accelerated aging test

Date:2021-11-03 16:11:00

What does acetone include? Standard for acetone detection method

Date:2021-11-03 14:56:50

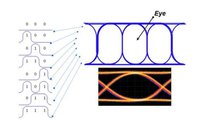

Eye diagram test - electrical performance test

Date:2021-11-02 17:11:10

Circuit noise - electrical performance test

Date:2021-11-02 16:19:32

Temperature rise test - electrical performance test

Date:2021-11-02 15:15:48

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou