What is the purpose of IC chip baking? What are the conditions and requirements?

Date:2021-11-11 11:39:44

What are the key function tests of PCBA processing? What should be noted during testing?

Date:2021-11-10 15:31:41

Principle, advantages and reference standards of X-ray technology detection chip

Date:2021-11-09 13:54:46

Failure analysis mechanism: analysis of poor performance of PCBA in welding

Date:2021-11-09 13:37:00

What do you mean by opening the cover? Summary of common problems in cover opening test

Date:2021-11-08 18:25:01

Rapid temperature change test - Reliability Test

Date:2021-11-05 15:00:00

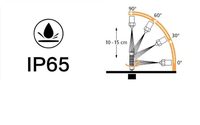

IP dustproof and waterproof test

Date:2021-11-05 14:10:00

Waterproof test - Reliability Test

Date:2021-11-05 13:30:00

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou