Sharing of sample selection methods for metallographic analysis

Date:2022-11-07 16:28:00

Several Mosaic Methods of Metallographic Specimens

Date:2022-11-07 16:00:00

Introduction of commonly used methods for measuring the depth of decarburized layer

Date:2022-11-04 14:30:00

How to grind the metallographic specimen? Detailed step process

Date:2022-11-04 14:08:00

Summary of problems in X-ray weld inspection of electronic components

Date:2022-10-28 16:15:02

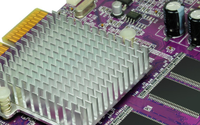

What are the contents of chip testing? IC Chip Reliability Test Standard

Date:2022-10-28 16:13:28

How to choose the appropriate burning mode for different chip models?

Date:2022-10-27 11:00:00

What is the purpose of FMEA for the three elements of fmea risk assessment?

Date:2022-10-27 11:00:00

Low temperature welding tools and precautions for electronic components

Date:2022-10-26 16:13:45

How to select NDT methods? Comparison of four NDT methods

Date:2022-10-26 16:11:44

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou