Characteristic analysis and function of Nondestructive Testing Technology

Date:2022-02-21 14:29:00

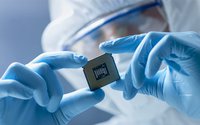

Integrated IC visual inspection component appearance defect detection

Date:2022-02-21 14:00:00

What is a low temperature test? Low temperature test conditions and methods

Date:2022-02-21 13:39:29

Basic principle and characteristics of ultrasonic nondestructive testing

Date:2022-02-21 13:25:02

Introduction to the basic principles and methods of chemical composition analysis

Date:2022-02-18 16:23:00

Why do we do damp heat test? Importance of alternating damp heat test

Date:2022-02-18 16:20:00

What are the chemical composition analysis? Demand for samples and use methods

Date:2022-02-18 16:00:00

Knowledge related to electronic product inspection third party testing organization

Date:2022-02-17 18:08:31

Welding estimation and testing methods of metal materials and their performance influencing factors

Date:2022-02-16 18:17:03

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou