Basic knowledge of patch welding three common welding technologies

Date:2022-03-03 15:23:00

Visual inspection scope, working principle and characteristics of nondestructive test

Date:2022-03-03 14:55:00

What are the common components on the PCB? Professional chip test

Date:2022-03-03 14:15:00

Test items and standards of IC chip electrical performance test

Date:2022-03-02 17:56:00

What are the reasons for the damage of electronic chips? Method for measuring chip quality

Date:2022-03-02 17:18:00

Electronic test items: 8 methods of circuit fault analysis

Date:2022-03-01 18:08:00

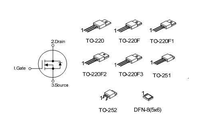

Main specifications and parameters of MOS field effect tube

Date:2022-03-01 16:38:00

Welding knowledge: reflow technical index and defect analysis and treatment

Date:2022-02-28 15:21:45

How to deal with chip failure analysis? Third party testing unit

Date:2022-02-28 14:43:00

X-ray nondestructive testing is used for casting quality inspection

Date:2022-02-28 14:22:00

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou