What principles should be paid attention to in the process design of welded structure?

Date:2021-10-12 13:03:54

What are the welding materials? General principles for selecting welding materials

Date:2021-10-12 13:00:00

Application and advantages of visual inspection system in appearance inspection

Date:2021-09-30 13:42:44

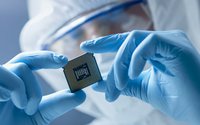

Introduction to main equipment for semiconductor appearance inspection and performance test

Date:2021-09-29 14:20:00

How should the company deal with the failure analysis of electronic components?

Date:2021-09-28 18:13:55

Failure analysis of electronic products: what is the cause of component failure?

Date:2021-09-28 18:03:14

What should we pay attention to in incoming inspection of components? What is included?

Date:2021-09-28 15:10:16

Testing tips: what tests are included in performance testing?

Date:2021-09-28 15:03:28

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou