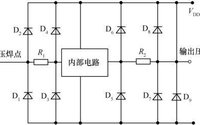

Common methods to improve reliability in integrated circuit design

Date:2021-07-23 16:52:00

What are the characteristics of electronic products? How to improve the reliability of components?

Date:2021-07-23 16:19:00

Basic principles of reliability design detailed version with PDF information for free download

Date:2021-07-23 16:00:00

What conditions do CNAs certified laboratories need to meet? How to rectify the nonconformities?

Date:2021-07-22 13:48:24

What is CNAs certification? Here comes the specific process of applying for CNAs certification

Date:2021-07-22 13:19:00

Mature process chips are in short supply, and manufacturers see the right time to expand production

Date:2021-07-22 10:24:00

Super full summary! List of standards for reliability test of military and civil products

Date:2021-07-21 14:23:00

What are the environmental protection test items of components? Handling of ROHS test report

Date:2021-07-21 11:44:00

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou