SERVICE

-

IC Counterfeit Detection

- IC Counterfeit Detection-Introduce

-

Non-Destructive Testing (NDT)

-

Destructive Testing

-

Value-Added Services

-

Destructive Physical Analysis (DPA)

- Destructive Physical Analysis (DPA)-Introduce

- External Visual Inspection

- X-Ray inspection

- Functional Testing (FT)

- Particle Impact Noise Detection (PIND/PIN-D)

- Hermeticity

- Internal Water Vapor

- Scanning Acoustic Tomography (SAT Testing)

- Solderability Test

- Decapsulation/Delid Test

- Bond Strength

- Die Shear Strength

- Configuration

-

Failure analysis

- Failure analysis-Introduce

-

Non-Destructive Analysis

-

Electrical Testing

-

Fault Location

-

Destructive Physical Analysis (DPA)

-

Physical Analysis

-

Engineering Sample (ES) Packaging Service

-

Competitor Analysis

-

Development and Functional Verification

- Development and Functional Verification-Introduce

-

New Product Development Testing (FT)

-

Key Functional Testing

-

Materials Analysis

- Materials Analysis-Introduce

-

FIB Circuit Edit

-

Structural Observation

-

Compositional Analysis

- EDS Analysis

-

Reliability Testing

- Reliability Testing-Introduce

-

Reliability Verification of Automotive Integrated Circuits (ICs)

-

Environmental Testing

-

Mechanical Testing

- Pull Test

- Die Strength Test

- High Strain Rate Test - Vibration Test

- Low Strain Rate Test - Bending Test

- High Strain Rate Test - Mechanical Shock Test

- Package Assembly Integrity Test - Wire Bonding Integrity

- Package Assembly Integrity Test

- Combined Vibration/Temperature/Humidity Test

- Combined Temperature/Humidity/Vibration/Altitude Test

- Free Fall Drop Test

- Box Compressive Strength Test

-

Corrosion Testing

-

IP Waterproof/Dust Resistant Test

-

Electromagnetic Compatibility (EMC)

- Electromagnetic Compatibility (EMC)-Introduce

- Immunity to Conducted Disturbances, Induced by Radio Frequency (RF) Fields

- Conducted Immunity Test

- Specific Absorption Rate (SAR) Testing for Electromagnetic Radiation

- Electrical Fast Transient/Burst (EFT/B) Test

- Voltage Flicker/Fluctuation Test

- Voltage Dips, Short Interruptions and Voltage Variations Immunity Test

- Power Frequency Magnetic Field (PFMF) Immunity Test

- Harmonic Interference Test

- Electrostatic Discharge (ESD) Immunity Test

- Surge/Lightning Immunity Test

- Radiated Emissions (RE) Test

- Radio Frequency (RF) Test

-

Chemical Analysis

- Chemical Analysis-Introduce

-

High-Performance Liquid Chromatography (HPLC)

-

Pyrolysis-Gas Chromatography-Mass Spectrometry (PY-GC-MS)

-

Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES)

- Flame Retardancy Test

Description:Scanning acoustic microscopy (SAM), also denominated acoustic micro imaging (AMI) and scanning acoustic tomography (SAT), is a non-destructive testing method. It utilizes the contrast between images and acoustic waves to analyze the internal layers of specimens, determine defect shapes and sizes, and identify defect orientations. It can also detect the counterfeit detection of surface printing duplication, surface grinding, and re-coating on integrated circuits.

Our Strengths:ChuangXin Testing Center is equipped with a complete range of probes, ranging from low frequencies such as 15MHz, 30MHz, 50MHz, 75MHz, to high frequencies like 100MHz and 230MHz. These probes can meet the testing requirements of integrated circuits and PCB boards with various packaging types such as SOP, DIP, PLCC, TO, QFP, BGA, SOT, QFN, TQFP, DFN, Flip Chip, WLCSP, FCBGA, as well as IGBTs and capacitors and so on.

Image of Scanning Acoustic Tomography Equipment:

Case Studies:

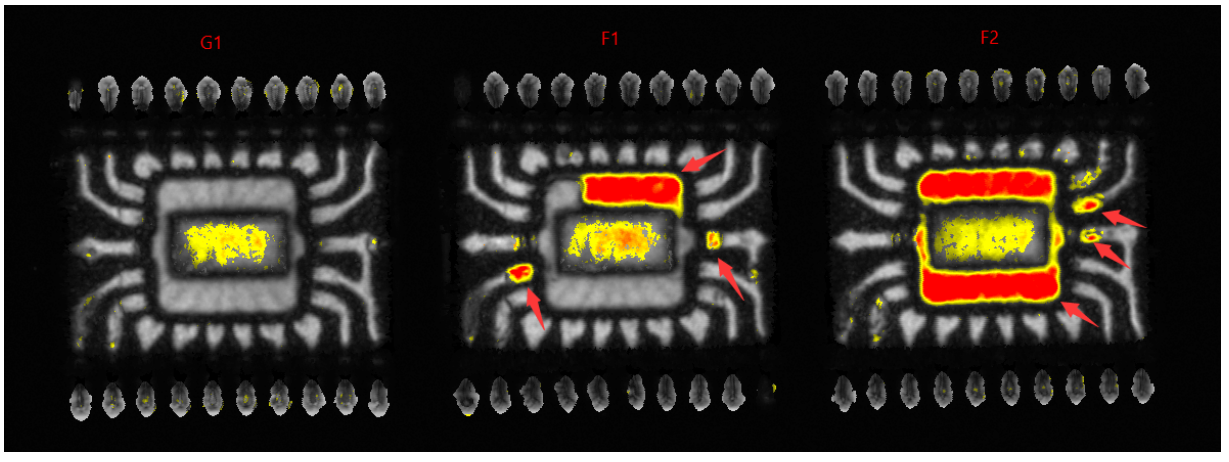

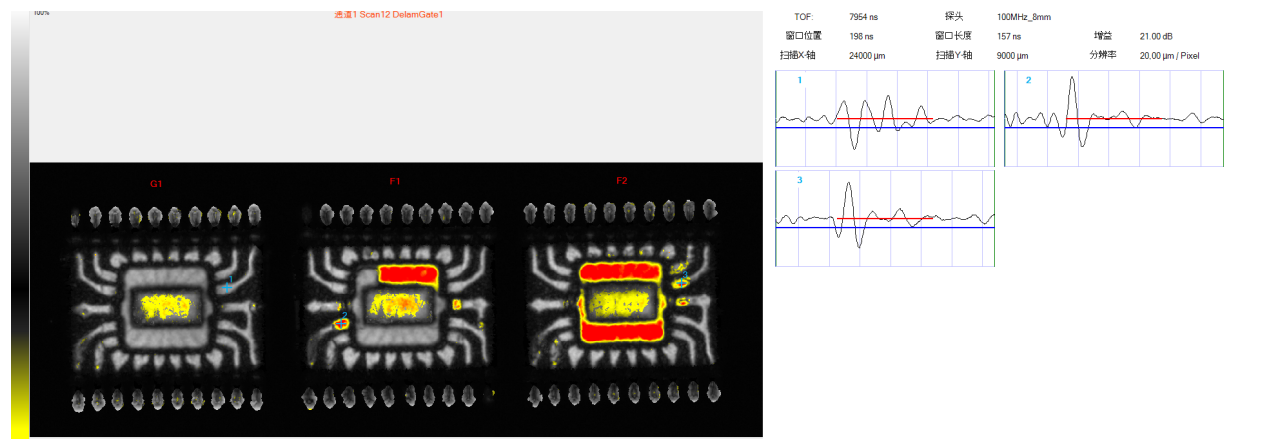

1.Abnormal Case in SOP Package:

Delamination Anomalies Between Internal Pins, Substrate Surface, and Encapsulation Interface (Reflection-Mode View)

Delamination Anomalies Between Internal Pins, Substrate Surface, and Encapsulation Interface (Reflection-Mode Waveform View)

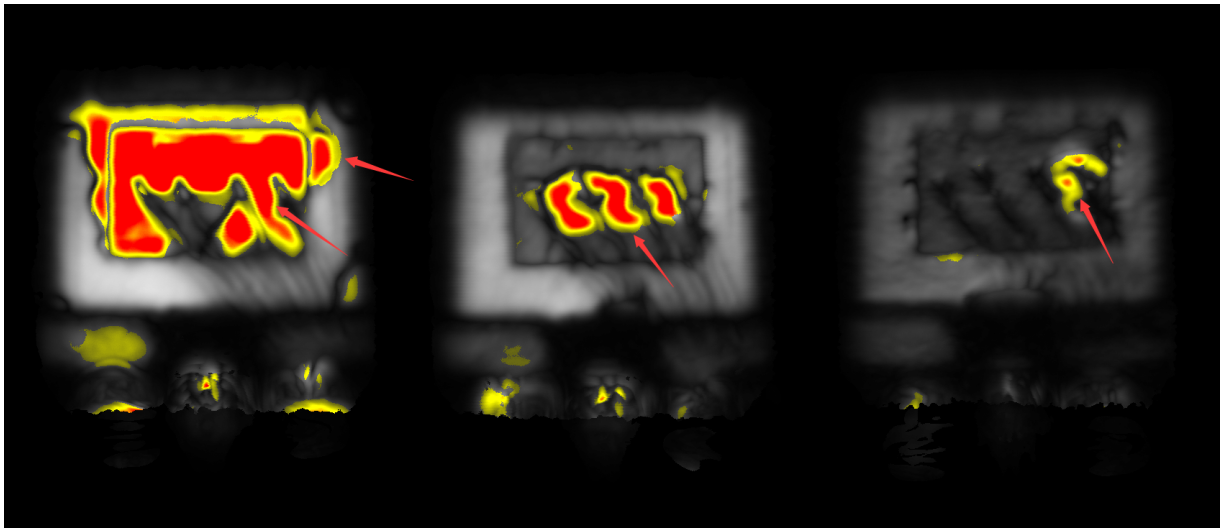

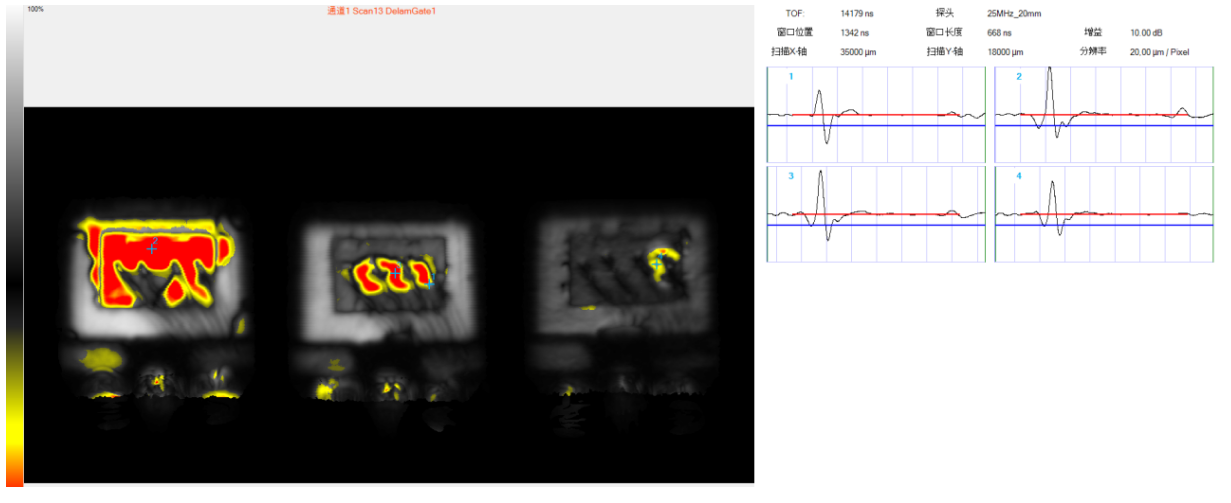

2. Abnormal Case in TO Package:

Delamination Anomalies Between Wafer, Substrate Surface, and Encapsulation Interface (Reflection-Mode View)

Delamination Anomalies Between Wafer, Substrate Surface, and Encapsulation Interface (Reflection-Mode Waveform View)

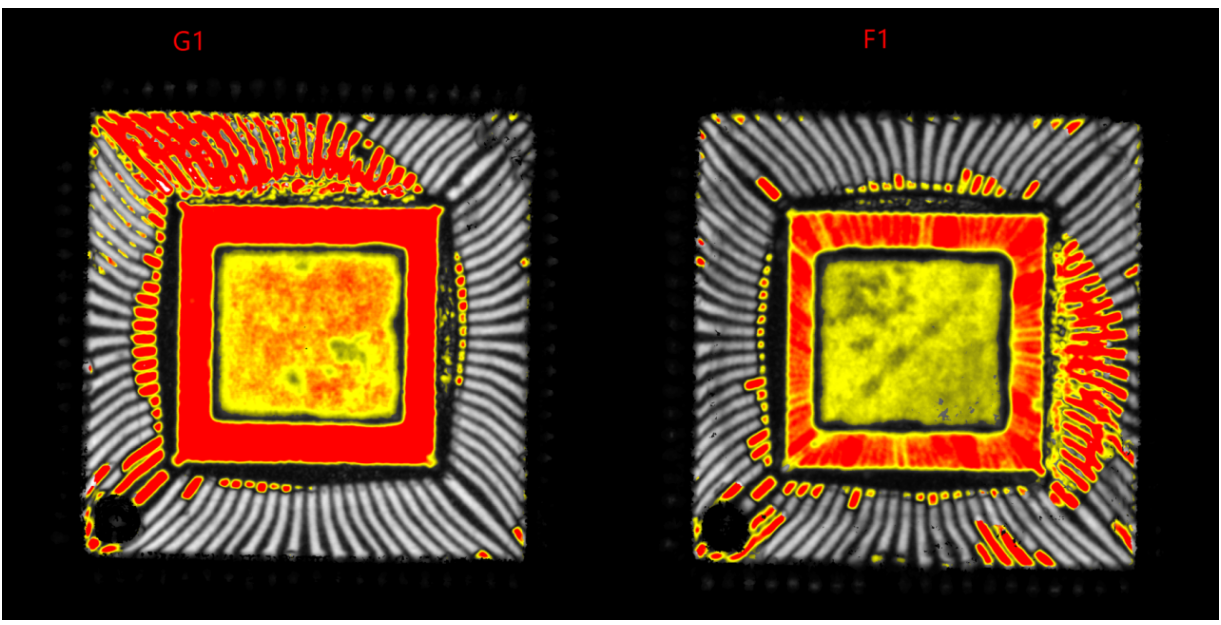

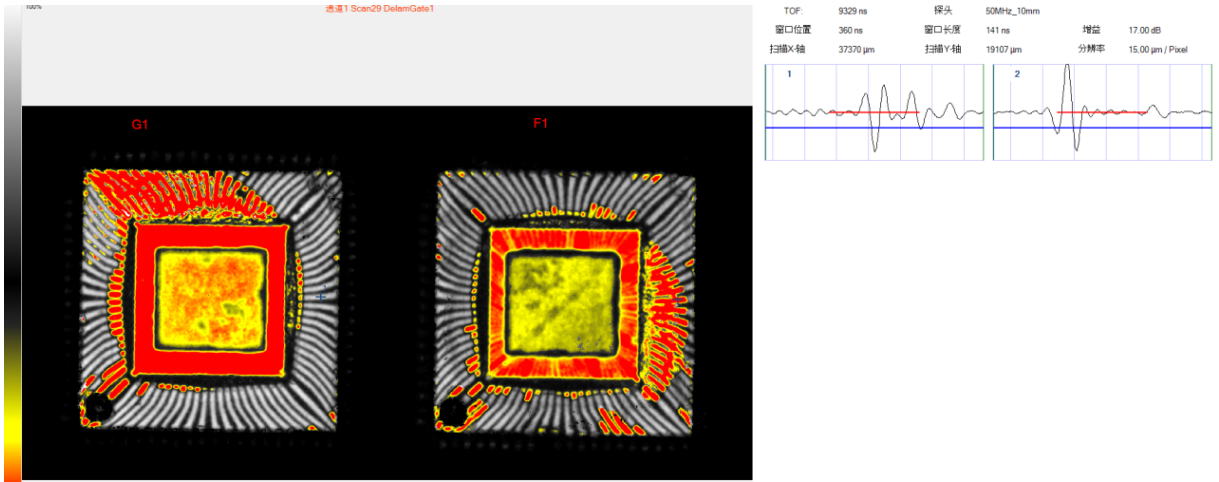

3. Abnormal Case in QFP Package:

Delamination Anomalies Between Internal Pins, Substrate Surface, and Encapsulation Interface (Reflection-Mode View)

Delamination Anomalies Between Internal Pins, Substrate Surface, and Encapsulation Interface (Reflection-Mode Waveform View)

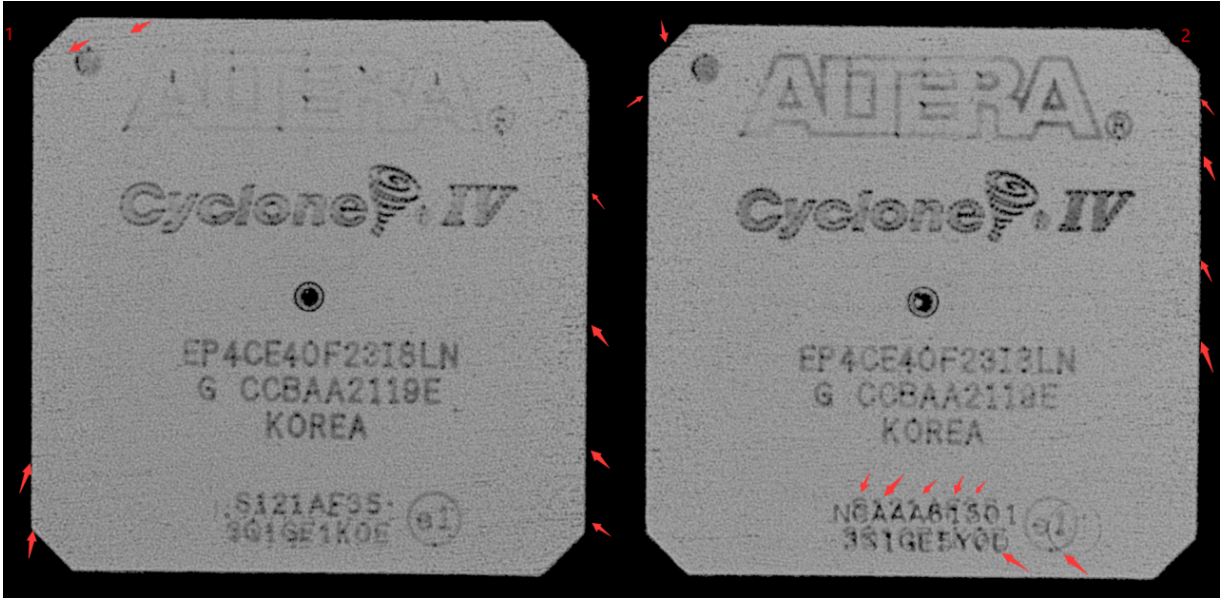

4. Abnormal Case in Counterfeit Detection:

Surface Printing Duplication, Abnormal Edge Grinding Marks (Reflection-Mode View)

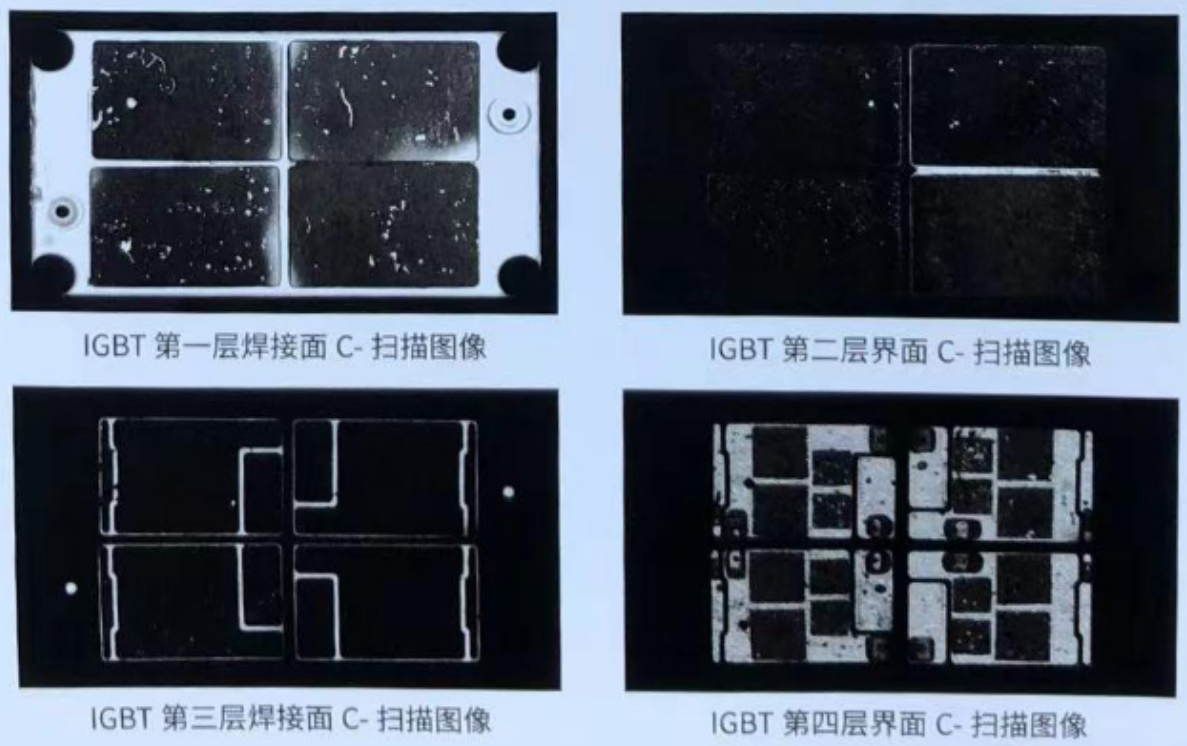

5.IGBT Testing Case:

First layer: Solder side between the heat-dissipated copper substrate and the bottom copper-clad layer of the DBC ceramic substrate;

Second layer: Interface between the bottom copper-clad layer of the DBC ceramic substrate and the ceramic;

Third layer: Interface between the ceramic of the DBC ceramic substrate and the upper copper-clad layer;

Fourth layer: Solder side between the upper copper-clad layer of the DBC ceramic substrate and the chip

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou