SERVICE

-

IC Counterfeit Detection

- IC Counterfeit Detection-Introduce

-

Non-Destructive Testing (NDT)

-

Destructive Testing

-

Value-Added Services

-

Destructive Physical Analysis (DPA)

- Destructive Physical Analysis (DPA)-Introduce

- External Visual Inspection

- X-Ray inspection

- Functional Testing (FT)

- Particle Impact Noise Detection (PIND/PIN-D)

- Hermeticity

- Internal Water Vapor

- Scanning Acoustic Tomography (SAT Testing)

- Solderability Test

- Decapsulation/Delid Test

- Bond Strength

- Die Shear Strength

- Configuration

-

Failure analysis

- Failure analysis-Introduce

-

Non-Destructive Analysis

-

Electrical Testing

-

Fault Location

-

Destructive Physical Analysis (DPA)

-

Physical Analysis

-

Engineering Sample (ES) Packaging Service

-

Competitor Analysis

-

Development and Functional Verification

- Development and Functional Verification-Introduce

-

New Product Development Testing (FT)

-

Key Functional Testing

-

Materials Analysis

- Materials Analysis-Introduce

-

FIB Circuit Edit

-

Structural Observation

-

Compositional Analysis

- EDS Analysis

-

Reliability Testing

- Reliability Testing-Introduce

-

Reliability Verification of Automotive Integrated Circuits (ICs)

-

Environmental Testing

-

Mechanical Testing

- Pull Test

- Die Strength Test

- High Strain Rate Test - Vibration Test

- Low Strain Rate Test - Bending Test

- High Strain Rate Test - Mechanical Shock Test

- Package Assembly Integrity Test - Wire Bonding Integrity

- Package Assembly Integrity Test

- Combined Vibration/Temperature/Humidity Test

- Combined Temperature/Humidity/Vibration/Altitude Test

- Free Fall Drop Test

- Box Compressive Strength Test

-

Corrosion Testing

-

IP Waterproof/Dust Resistant Test

-

Electromagnetic Compatibility (EMC)

- Electromagnetic Compatibility (EMC)-Introduce

- Immunity to Conducted Disturbances, Induced by Radio Frequency (RF) Fields

- Conducted Immunity Test

- Specific Absorption Rate (SAR) Testing for Electromagnetic Radiation

- Electrical Fast Transient/Burst (EFT/B) Test

- Voltage Flicker/Fluctuation Test

- Voltage Dips, Short Interruptions and Voltage Variations Immunity Test

- Power Frequency Magnetic Field (PFMF) Immunity Test

- Harmonic Interference Test

- Electrostatic Discharge (ESD) Immunity Test

- Surge/Lightning Immunity Test

- Radiated Emissions (RE) Test

- Radio Frequency (RF) Test

-

Chemical Analysis

- Chemical Analysis-Introduce

-

High-Performance Liquid Chromatography (HPLC)

-

Pyrolysis-Gas Chromatography-Mass Spectrometry (PY-GC-MS)

-

Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES)

- Flame Retardancy Test

Description:

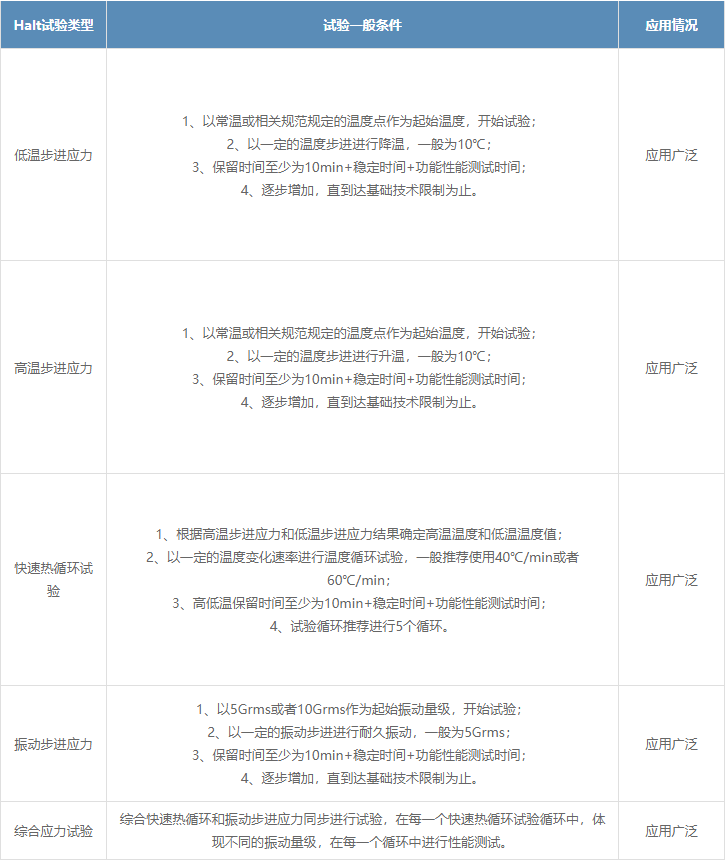

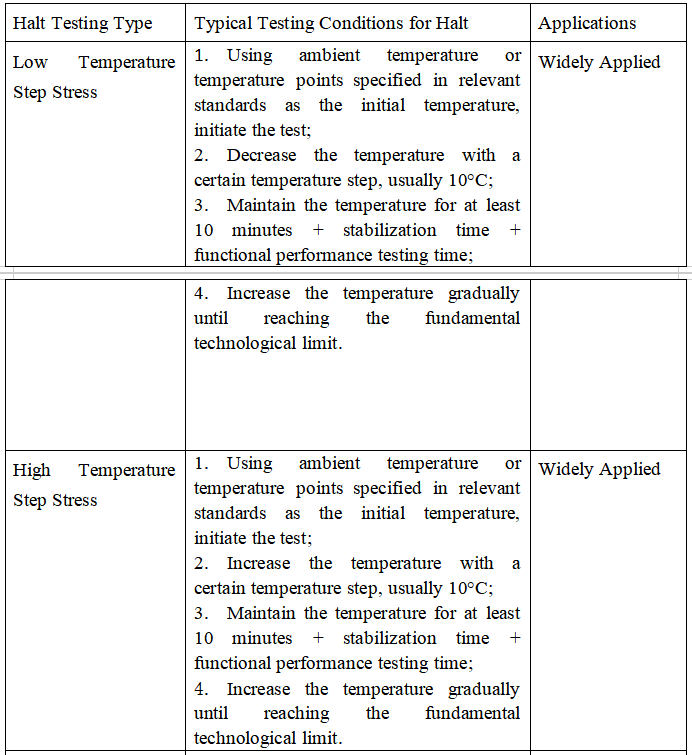

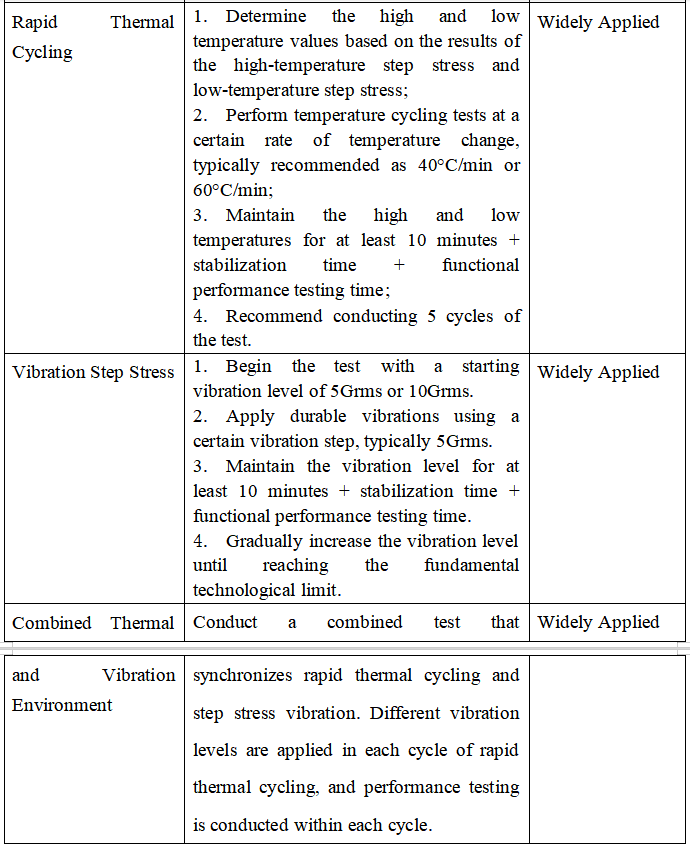

Highly Accelerated Life Testing (HALT) is a process used to identify design flaws in which progressively increasing levels of accelerated environmental stress are applied to test samples. This process aims to expose weaknesses and defects in the samples, allowing for analysis and improvement of the design, manufacturing process, and materials to enhance reliability. A key characteristic of HALT is the application of stress levels that exceed the operational limits of the sample design, significantly shortening the time required to expose failures compared to normal reliability stress conditions.

Purpose: HALT is aimed to determine the operational and destruction limits of the tested object under temperature and vibration stress conditions; to provide developers with a basis for improving product design by identifying and addressing design flaws in a timely manner; to guide the selection of stress types and levels for HASS (Highly Accelerated Stress Screening).

Benefits: Rapidly identifying weaknesses in product design and manufacturing processes; Improving product design robustness; Enhancing product reliability effectively; Saving design time and costs; Troubleshooting product design issues; Assisting in evaluating design changes.

Principle: Evaluating pass/fail criteria; Testing samples until failure occurs; Real-time monitoring of the samples during testing; Analyzing any problems discovered during the test to determine the cause of failure; Noting that the results obtained from the test cannot be used to quantify the reliability of the product.

Scope of Application :

Electrical and electronic components such as electronics, components, printed circuit boards (PCBs), and others.

Testing Items:

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou