SERVICE

-

IC Counterfeit Detection

- IC Counterfeit Detection-Introduce

-

Non-Destructive Testing (NDT)

-

Destructive Testing

-

Value-Added Services

-

Destructive Physical Analysis (DPA)

- Destructive Physical Analysis (DPA)-Introduce

- External Visual Inspection

- X-Ray inspection

- Functional Testing (FT)

- Particle Impact Noise Detection (PIND/PIN-D)

- Hermeticity

- Internal Water Vapor

- Scanning Acoustic Tomography (SAT Testing)

- Solderability Test

- Decapsulation/Delid Test

- Bond Strength

- Die Shear Strength

- Configuration

-

Failure analysis

- Failure analysis-Introduce

-

Non-Destructive Analysis

-

Electrical Testing

-

Fault Location

-

Destructive Physical Analysis (DPA)

-

Physical Analysis

-

Engineering Sample (ES) Packaging Service

-

Competitor Analysis

-

Development and Functional Verification

- Development and Functional Verification-Introduce

-

New Product Development Testing (FT)

-

Key Functional Testing

-

Materials Analysis

- Materials Analysis-Introduce

-

FIB Circuit Edit

-

Structural Observation

-

Compositional Analysis

- EDS Analysis

-

Reliability Testing

- Reliability Testing-Introduce

-

Reliability Verification of Automotive Integrated Circuits (ICs)

-

Environmental Testing

-

Mechanical Testing

- Pull Test

- Die Strength Test

- High Strain Rate Test - Vibration Test

- Low Strain Rate Test - Bending Test

- High Strain Rate Test - Mechanical Shock Test

- Package Assembly Integrity Test - Wire Bonding Integrity

- Package Assembly Integrity Test

- Combined Vibration/Temperature/Humidity Test

- Combined Temperature/Humidity/Vibration/Altitude Test

- Free Fall Drop Test

- Box Compressive Strength Test

-

Corrosion Testing

-

IP Waterproof/Dust Resistant Test

-

Electromagnetic Compatibility (EMC)

- Electromagnetic Compatibility (EMC)-Introduce

- Immunity to Conducted Disturbances, Induced by Radio Frequency (RF) Fields

- Conducted Immunity Test

- Specific Absorption Rate (SAR) Testing for Electromagnetic Radiation

- Electrical Fast Transient/Burst (EFT/B) Test

- Voltage Flicker/Fluctuation Test

- Voltage Dips, Short Interruptions and Voltage Variations Immunity Test

- Power Frequency Magnetic Field (PFMF) Immunity Test

- Harmonic Interference Test

- Electrostatic Discharge (ESD) Immunity Test

- Surge/Lightning Immunity Test

- Radiated Emissions (RE) Test

- Radio Frequency (RF) Test

-

Chemical Analysis

- Chemical Analysis-Introduce

-

High-Performance Liquid Chromatography (HPLC)

-

Pyrolysis-Gas Chromatography-Mass Spectrometry (PY-GC-MS)

-

Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES)

- Flame Retardancy Test

Description:

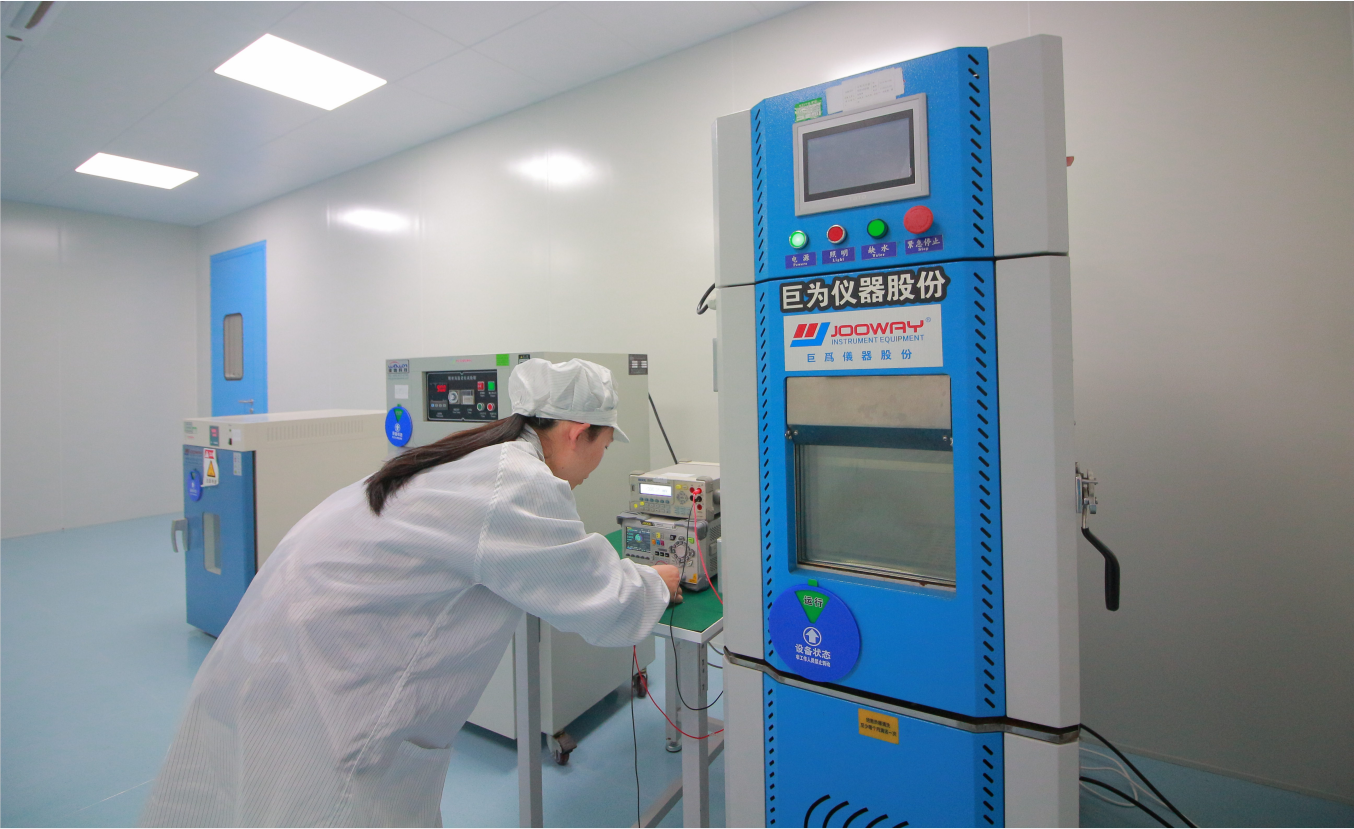

Thermal cycling test is a test in which samples are exposed to alternating environments of set temperatures and humidity to evaluate changes in the functional characteristics of the samples after temperature and humidity cycling or storage.

The storage and working environments of products are subject to certain temperatures and humidity, which constantly vary. For example, temperature differences between day and night, different humidity levels at different temperatures and times, and exposure to different temperature and humidity regions during transportation. These alternating temperature and humidity environments can affect the performance and lifespan of products, accelerating their aging process. Temperature cycling simulates the temperature and humidity environments in which products are stored and used, and tests whether the effects on the products within a certain period of time are within acceptable limits.

Purpose: To verify the ability of products and materials to withstand environmental changes under high and low temperature and atmospheric humidity conditions.

Purpose of high and low temperature cycling test: To test the impact of thermal stress on product performance after long-term exposure to alternating hot and cold temperatures.

Purpose of humidity test: To test the degradation characteristics of products under high temperature and high humidity conditions, evaluate the moisture absorption and condensation characteristics of materials, and assess the storage and performance of products under humid conditions.

Test Failures: Material expansion due to water absorption, loss of physical strength, changes in chemical properties, degradation of insulation performance, corrosion of components, failure of lubricants, oxidation of materials, loss of ductility, accelerated chemical reactions, degradation of electronic components.

Scope of Application:

Instrumentation materials, electrical engineering, electronic products, household appliances, automotive parts, chemical coatings, aerospace products, and other related product components.

Image of Thermal Cycling Testing Equipment:

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou