SERVICE

-

IC Counterfeit Detection

- IC Counterfeit Detection-Introduce

-

Non-Destructive Testing (NDT)

-

Destructive Testing

-

Value-Added Services

-

Destructive Physical Analysis (DPA)

- Destructive Physical Analysis (DPA)-Introduce

- External Visual Inspection

- X-Ray inspection

- Functional Testing (FT)

- Particle Impact Noise Detection (PIND/PIN-D)

- Hermeticity

- Internal Water Vapor

- Scanning Acoustic Tomography (SAT Testing)

- Solderability Test

- Decapsulation/Delid Test

- Bond Strength

- Die Shear Strength

- Configuration

-

Failure analysis

- Failure analysis-Introduce

-

Non-Destructive Analysis

-

Electrical Testing

-

Fault Location

-

Destructive Physical Analysis (DPA)

-

Physical Analysis

-

Engineering Sample (ES) Packaging Service

-

Competitor Analysis

-

Development and Functional Verification

- Development and Functional Verification-Introduce

-

New Product Development Testing (FT)

-

Key Functional Testing

-

Materials Analysis

- Materials Analysis-Introduce

-

FIB Circuit Edit

-

Structural Observation

-

Compositional Analysis

- EDS Analysis

-

Reliability Testing

- Reliability Testing-Introduce

-

Reliability Verification of Automotive Integrated Circuits (ICs)

-

Environmental Testing

-

Mechanical Testing

- Pull Test

- Die Strength Test

- High Strain Rate Test - Vibration Test

- Low Strain Rate Test - Bending Test

- High Strain Rate Test - Mechanical Shock Test

- Package Assembly Integrity Test - Wire Bonding Integrity

- Package Assembly Integrity Test

- Combined Vibration/Temperature/Humidity Test

- Combined Temperature/Humidity/Vibration/Altitude Test

- Free Fall Drop Test

- Box Compressive Strength Test

-

Corrosion Testing

-

IP Waterproof/Dust Resistant Test

-

Electromagnetic Compatibility (EMC)

- Electromagnetic Compatibility (EMC)-Introduce

- Immunity to Conducted Disturbances, Induced by Radio Frequency (RF) Fields

- Conducted Immunity Test

- Specific Absorption Rate (SAR) Testing for Electromagnetic Radiation

- Electrical Fast Transient/Burst (EFT/B) Test

- Voltage Flicker/Fluctuation Test

- Voltage Dips, Short Interruptions and Voltage Variations Immunity Test

- Power Frequency Magnetic Field (PFMF) Immunity Test

- Harmonic Interference Test

- Electrostatic Discharge (ESD) Immunity Test

- Surge/Lightning Immunity Test

- Radiated Emissions (RE) Test

- Radio Frequency (RF) Test

-

Chemical Analysis

- Chemical Analysis-Introduce

-

High-Performance Liquid Chromatography (HPLC)

-

Pyrolysis-Gas Chromatography-Mass Spectrometry (PY-GC-MS)

-

Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES)

- Flame Retardancy Test

Description:

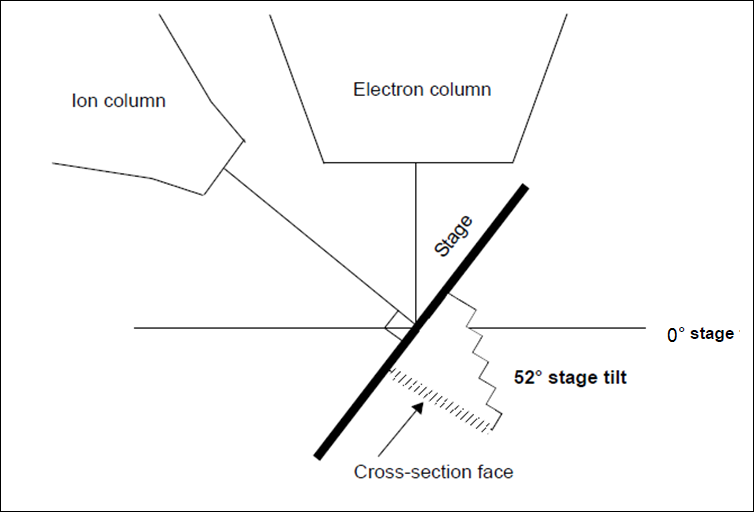

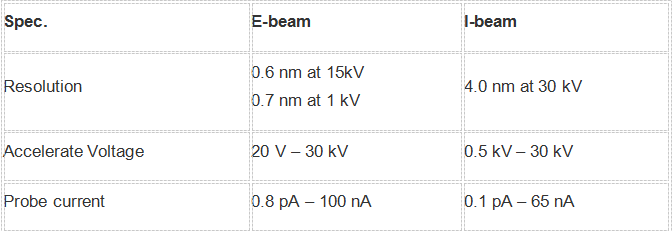

Dual-Beam FIB (Focused Ion Beam) machines use an ion beam to cut samples and an electron beam to observe the cross-section of the sample. They can also perform EDX (Energy Dispersive X-ray) elemental analysis.

Dual-Beam FIB has ultra-high-resolution ion and electron beams, allowing for nanoscale positioning and observation of fine structures in samples. The ion beam can provide a maximum current of up to 65nA, the excellent cutting speed can significantly shorten the analysis time and reduce experimental costs.

Scope of Application:

Failure analysis of semiconductor components and structure analysis (capable of reaching advanced processes down to 14 nm);

Process anomaly analysis in semiconductor production lines;

Analysis of epitaxy and thin film structures;

Preparation of transmission electron microscope (TEM) samples.

Testing Images:

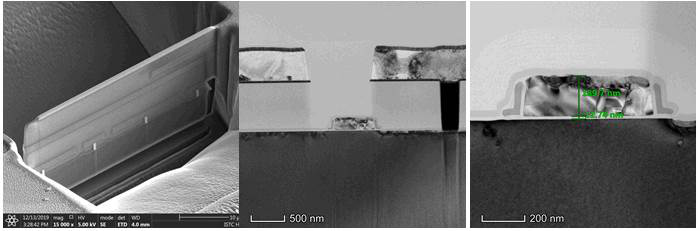

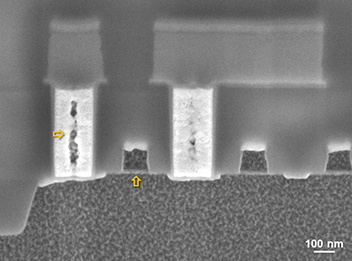

TEM Sample Preparation: TEM specimens with a thickness of approximately 15nm can be prepared using a layer-by-layer delayering technique.

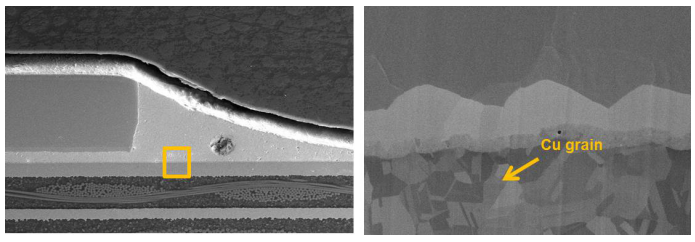

Copper Grain Analysis: By using special sample preparation techniques (grinding + ion milling), a large-area image of copper grains can be quickly obtained.

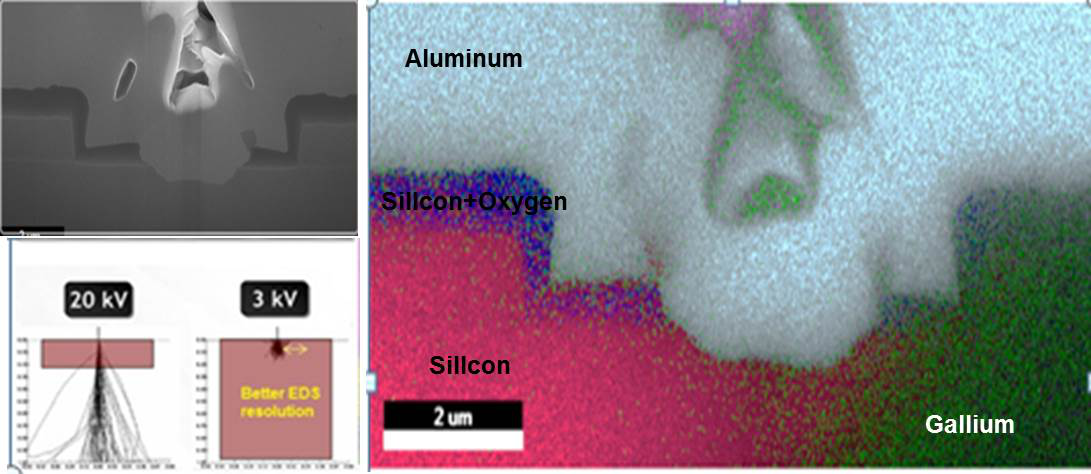

EDS Analysis: Large-area EDS detector (75 mm2) with excellent spatial resolution, is capable of high-end applications involving simultaneous cutting, imaging, and analysis.

Cross-section Analysis: The Helios NanoLab has excellent E-beam resolution, allowing clear visualization of voids and gate oxide with a resolution as fine as 3nm.

Images of Testing Equipment Energy:

FEI Helios NanoLab 660

Maximum sample size: 150mm;

Equipped with a 75mm2 SDD EDS detector for real-time EDS analysis;

Equipped with MultiChem gas system capable of introducing six types of deposition or stain gases;

When the observation width exceeds 100um or the depth exceeds 50um, it is recommended to switch to Plasma FIB, which has a faster cutting speed.

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou