SERVICE

-

IC Counterfeit Detection

- IC Counterfeit Detection-Introduce

-

Non-Destructive Testing (NDT)

-

Destructive Testing

-

Value-Added Services

-

Destructive Physical Analysis (DPA)

- Destructive Physical Analysis (DPA)-Introduce

- External Visual Inspection

- X-Ray inspection

- Functional Testing (FT)

- Particle Impact Noise Detection (PIND/PIN-D)

- Hermeticity

- Internal Water Vapor

- Scanning Acoustic Tomography (SAT Testing)

- Solderability Test

- Decapsulation/Delid Test

- Bond Strength

- Die Shear Strength

- Configuration

-

Failure analysis

- Failure analysis-Introduce

-

Non-Destructive Analysis

-

Electrical Testing

-

Fault Location

-

Destructive Physical Analysis (DPA)

-

Physical Analysis

-

Engineering Sample (ES) Packaging Service

-

Competitor Analysis

-

Development and Functional Verification

- Development and Functional Verification-Introduce

-

New Product Development Testing (FT)

-

Key Functional Testing

-

Materials Analysis

- Materials Analysis-Introduce

-

FIB Circuit Edit

-

Structural Observation

-

Compositional Analysis

- EDS Analysis

-

Reliability Testing

- Reliability Testing-Introduce

-

Reliability Verification of Automotive Integrated Circuits (ICs)

-

Environmental Testing

-

Mechanical Testing

- Pull Test

- Die Strength Test

- High Strain Rate Test - Vibration Test

- Low Strain Rate Test - Bending Test

- High Strain Rate Test - Mechanical Shock Test

- Package Assembly Integrity Test - Wire Bonding Integrity

- Package Assembly Integrity Test

- Combined Vibration/Temperature/Humidity Test

- Combined Temperature/Humidity/Vibration/Altitude Test

- Free Fall Drop Test

- Box Compressive Strength Test

-

Corrosion Testing

-

IP Waterproof/Dust Resistant Test

-

Electromagnetic Compatibility (EMC)

- Electromagnetic Compatibility (EMC)-Introduce

- Immunity to Conducted Disturbances, Induced by Radio Frequency (RF) Fields

- Conducted Immunity Test

- Specific Absorption Rate (SAR) Testing for Electromagnetic Radiation

- Electrical Fast Transient/Burst (EFT/B) Test

- Voltage Flicker/Fluctuation Test

- Voltage Dips, Short Interruptions and Voltage Variations Immunity Test

- Power Frequency Magnetic Field (PFMF) Immunity Test

- Harmonic Interference Test

- Electrostatic Discharge (ESD) Immunity Test

- Surge/Lightning Immunity Test

- Radiated Emissions (RE) Test

- Radio Frequency (RF) Test

-

Chemical Analysis

- Chemical Analysis-Introduce

-

High-Performance Liquid Chromatography (HPLC)

-

Pyrolysis-Gas Chromatography-Mass Spectrometry (PY-GC-MS)

-

Inductively Coupled Plasma Optical Emission Spectroscopy (ICP-OES)

- Flame Retardancy Test

Description:

Flicker measurements assess the effects of continuous voltage fluctuations, reflecting the unstable perceptual effects caused by time-varying light stimulation on human visual perception.

Test standard basis: IEC 61000-3-3/GB 17625.2 Electromagnetic compatibility-Limits-Limitation of voltage fluctuations and flicker in low-voltage power supply systems for equipment with rated current greater than 16A.

IEC standards specify: de does not exceed 3%; dd with a duration exceeding 3% is less than 200ms; dmax does not exceed 4%.

Voltage flicker: There are two main indicators used to assess flicker in power systems. Short-term flicker, Pst, and long-term flicker, Plt.

Short Term Flicker Perceptibility (Pst) is the measure over a short period (within 10 minutes) of how irritating flicker is thought to be and uses Pst=1 as the threshold for flicker perception. Pst simulates the flicker sensation produced by a 60W incandescent lamp operating on a 230V AC voltage in a 50Hz power grid under voltage fluctuation conditions.

Long Term Flicker Perceptibility (Plt) is a further measure for cumulative irritation over a longer period (within 2 hours), and the standard uses PLt=0.65 as the threshold for flicker perception.

Scope of Application:

Electronics and electrical products.

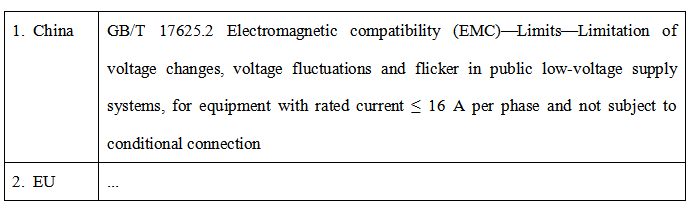

Applicable Countries and Standards:

![]()

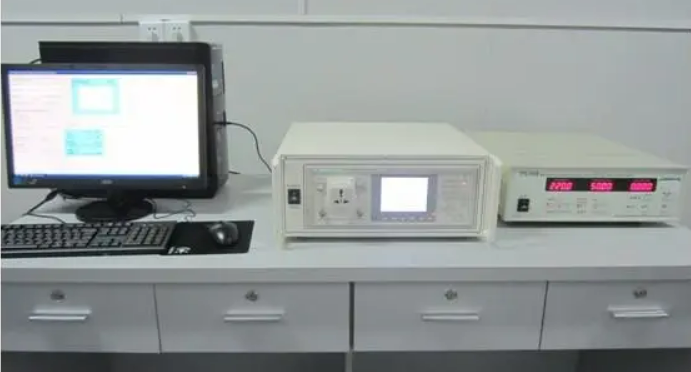

Image of Testing Equipment:

Weixin Service

Weixin Service

DouYin

DouYin

KuaiShou

KuaiShou